MTC Solutions beam hangers are tested pre-engineered connectors designed to meet the diverse needs of modern mass timber construction projects. These systems can all be preinstalled in a controlled shop environment, improving on-site assembly efficiency, reducing installation errors, and optimizing labor time and overall project costs.

This article gives a summary of MTC Solutions beam hangers, highlighting their features and installation configuration possibilities.

Approximately 8-minute read.

Performance Distinctions Between GIGANT, RICON S VS, and MEGANT

MTC beam hangers are proven through rigorous testing programs so engineers can specify them with confidence. Each of our beam hangers are designed for fast and repeatable drop-in installation, enabling a streamlined and efficient workflow. While all three systems share common benefits, such as pre-installability and the flexibility to be exposed or fully concealed for aesthetic preferences, they also have distinct structural performance advantages.

Whether it’s the MEGANT’s high-capacity, the RICON S VS’s hybrid compatibility, or the efficient simplicity of the GIGANT, each system is designed to meet structural and aesthetic goals with dependable, code-compliant performance.

The GIGANT is manufactured from mild steel, and consists of two identical brackets, one installed in the primary member and the other in the secondary member. Once installed, the two brackets simply hook into each other in a dovetail-like fashion.

The ICC-certified RICON S VS is made from mild steel with a welded collar bolt, and consists of two identical parts, one installed in the primary member and the other in the secondary member. Once installed, the collar bolt simply slides into the V-shaped notch.

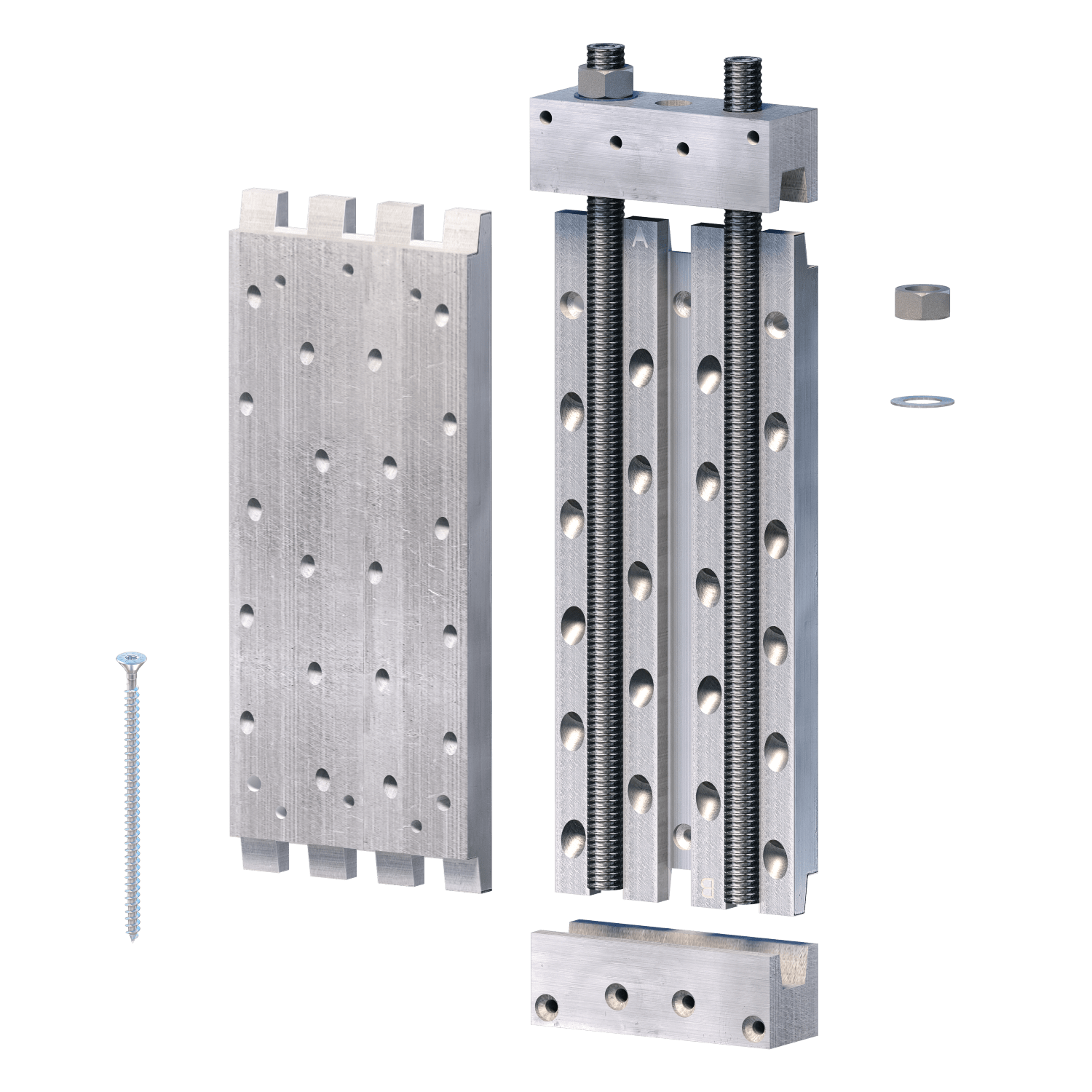

The MEGANT is manufactured from aluminum, and is a system composed of several pieces that tighten the system together; two plates, two clamping jaws, and one to two threaded rods, nuts, and washers.

*Connector capacity varies based on configuration and wood species they are installed in

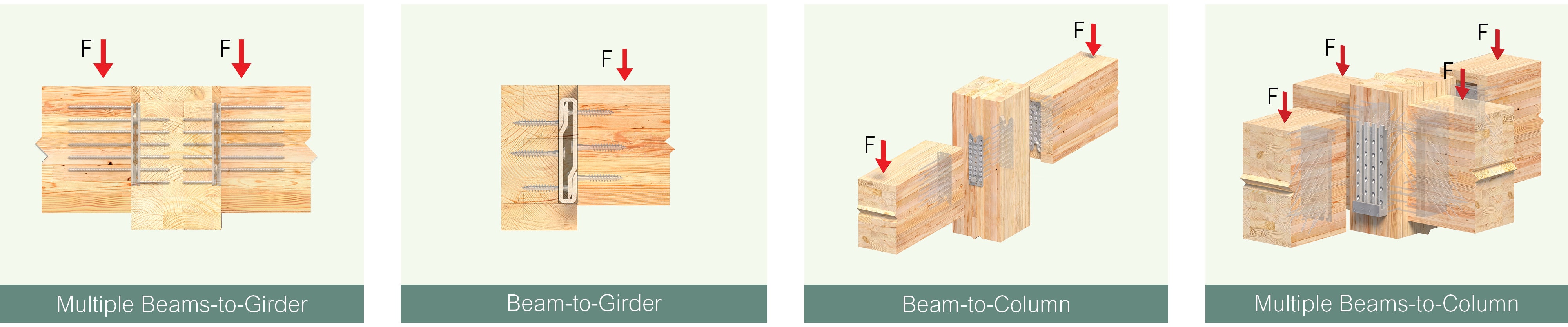

Commonly Used Beam Hanger Installation Configurations

The GIGANT, RICON S VS, and MEGANT are most commonly used in squared or perpendicular connections, such as beam-to-girder and beam-to-column connections. These connections are often concealed by routing the connector into either the primary or secondary member, resulting in a clean, architecturally pleasing finish.

In addition to their visual appeal, concealed configurations enhance fire resistance. During a fire, a protective char layer forms on the surface of the member, insulating the inner material and the concealed connector system. With the proper concealment details, all MTC Solutions beam hangers can achieve FRRs of up to two hours.

Refer to our blog post on Concealed Fire Rated Beam Hanger Systems for guidance on establishing fire-resistance-rated concealed connections using MTC Solutions beam hangers.

Alternative Applications

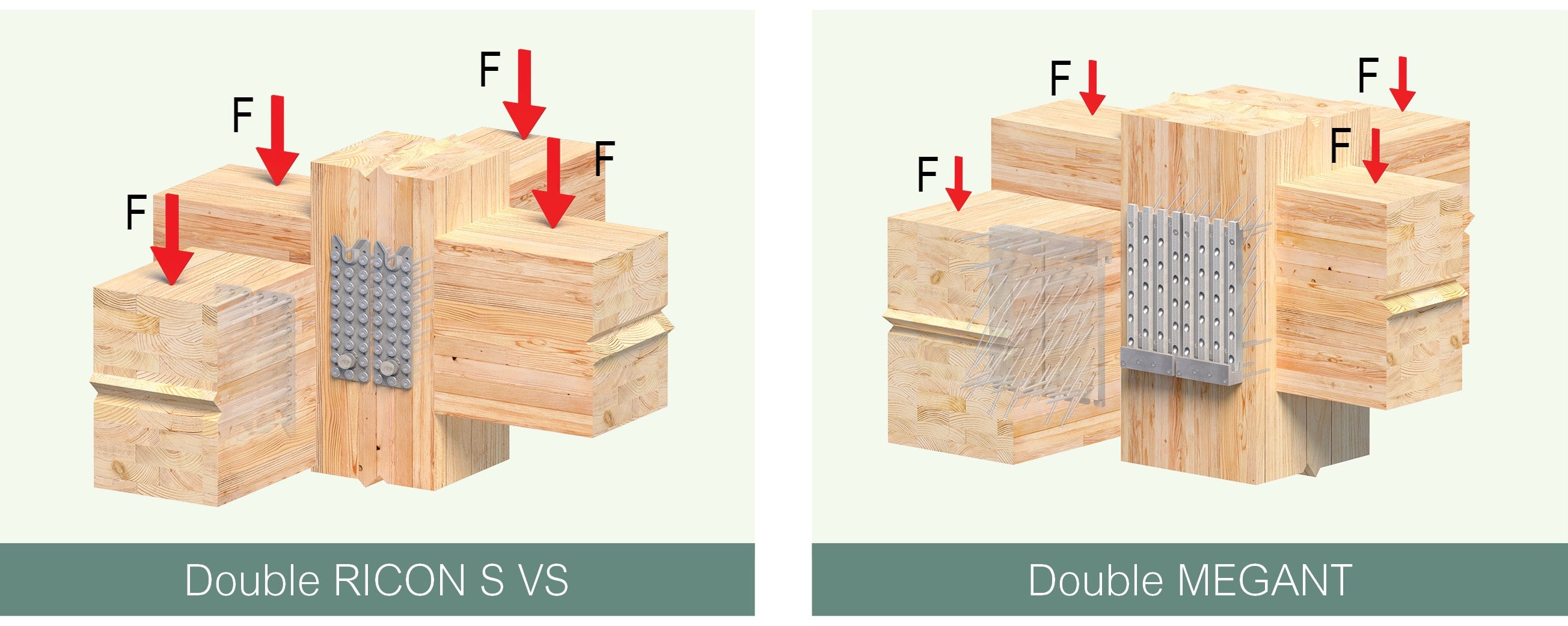

When higher connection capacities are required but architectural constraints limit beam sizes, both the RICON S VS and MEGANT systems can be installed in double configurations. This setup effectively increases connection strength without requiring oversized members, making it ideal for achieving structural performance while maintaining clean, compact beam dimensions.

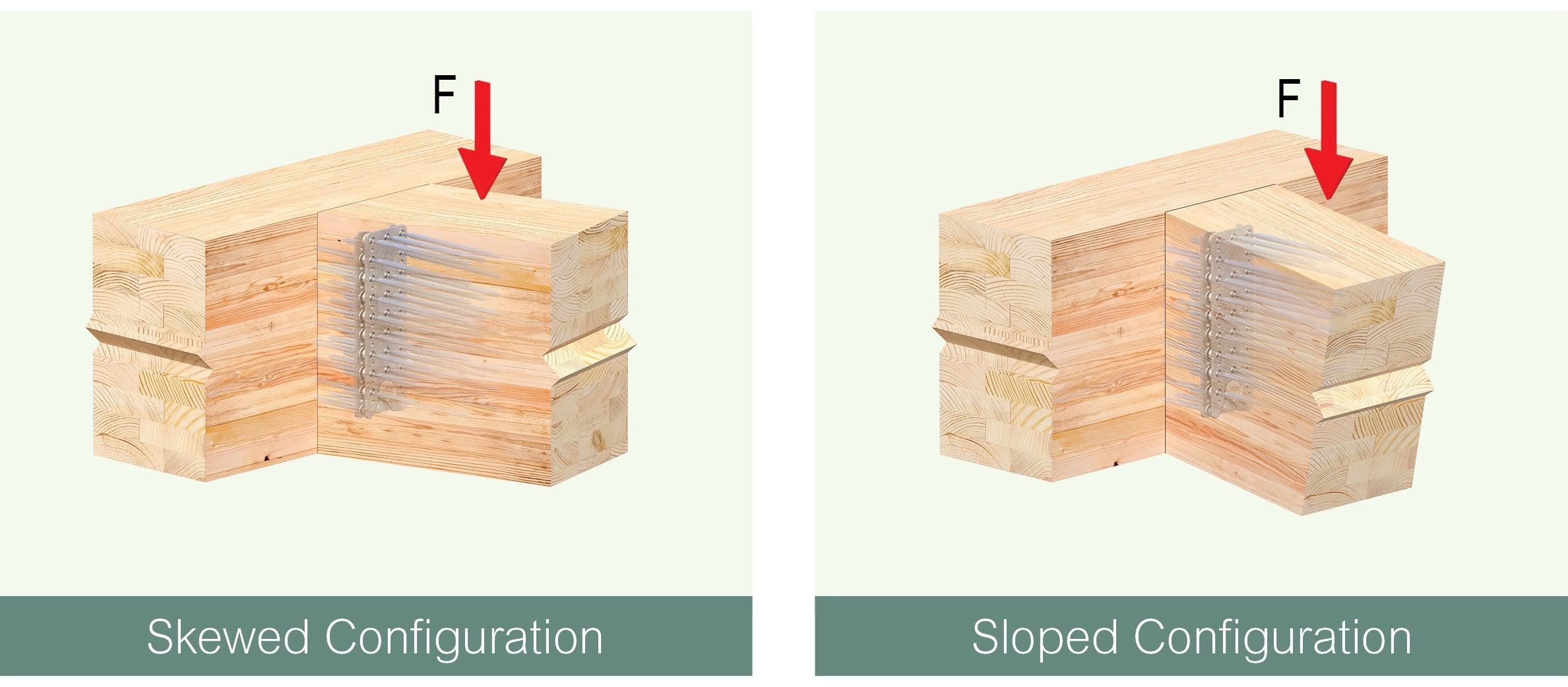

The RICON S VS system can also be used in sloped or skewed configurations, such as rafter-to-ridge beam or angled joist-to-beam connections. This added flexibility makes it a practical solution for projects with unique geometry considerations, allowing designers to maintain clean lines and meet distinct architectural and structural requirements with the same reliable, drop-in installation process.

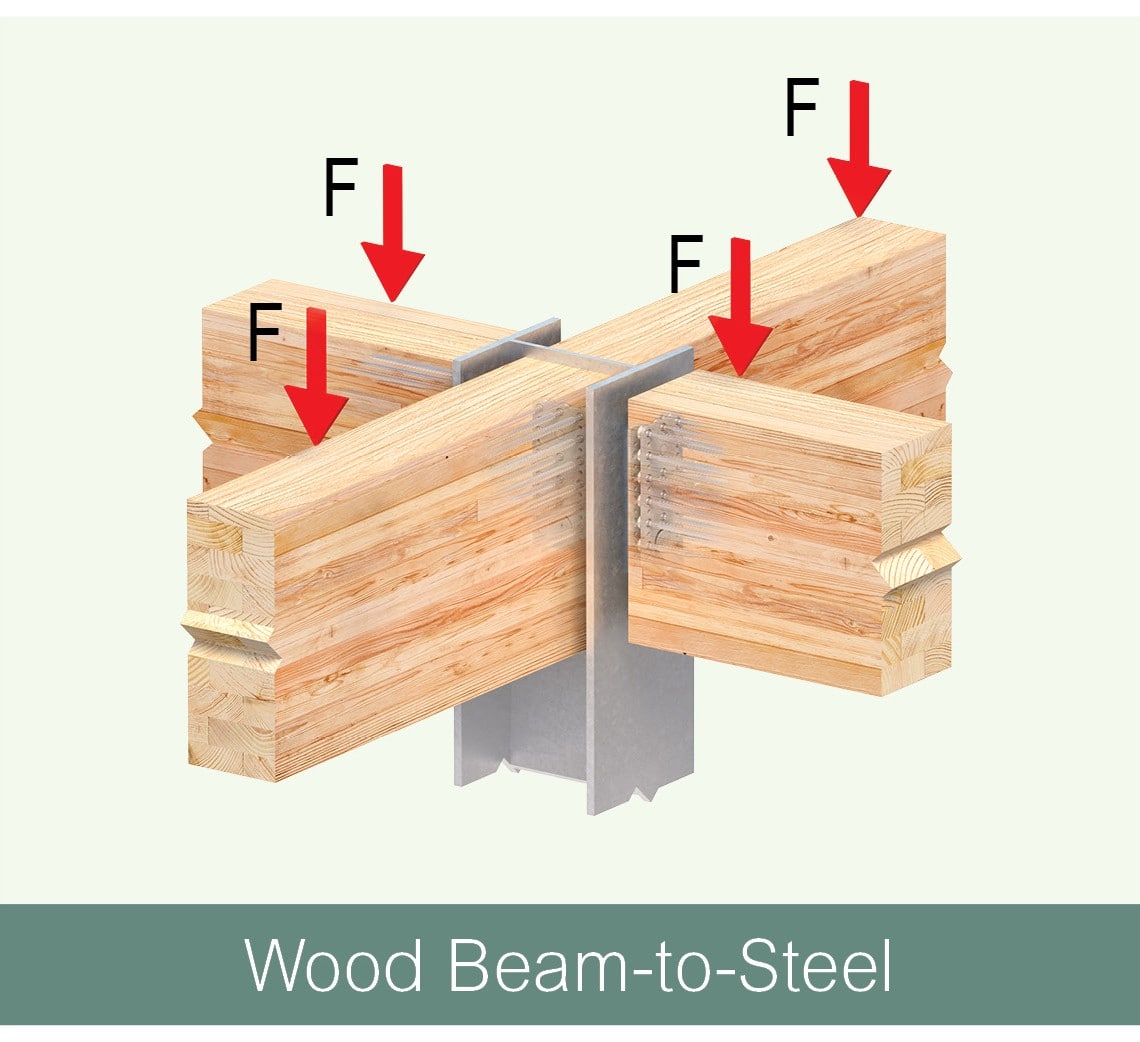

In addition to its wood-to-wood applications, the RICON S VS can be used in wood-to-steel or wood-to-concrete connections. This is achieved by welding the connector directly to the steel member or to a steel embed plate in concrete, expanding its use in hybrid construction projects.

MTC Solutions beam hangers offer versatile, tested connection solutions that optimize efficiency across every phase of mass timber construction projects—from design and detailing to installation. Backed by detailed tabulated design values and precise installation instructions, these pre-engineered products support cost optimization in the mass timber industry while providing reliable, code-compliant performance.

Download our Beam Hanger Design Guide to learn more about the specifics of how our beam hanger systems can bring added value to your project.

Have questions? Our Technical Support Team is here to help you find the right solution!

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.