Concealed connection systems are often selected for mass timber projects where the wood is a structural element and an architectural feature. Architects and designers often take advantage of the natural beauty of timber by leaving the wood exposed and hiding structural steel connections. Rather than encasing structural members in fireproofing materials such as gypsum board, leaving the wood exposed means that fire protection for the connection systems must be achieved through the combustible wood members themselves.

This blog post provides an overview of design guidelines to achieve fire-rated concealed post-to-beam and beam-to-girder connections using MTC Solutions pre-engineered Beam Hanger Systems.

Approximately 12-minute reading time.

Charring

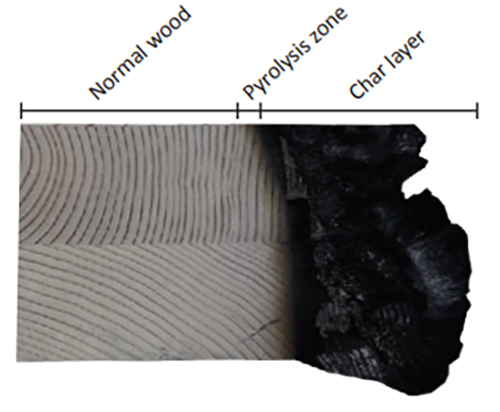

Heavy timber elements have long been recognized for having excellent performance in fire due to the beneficial effects of charring. In a fire event, a layer of char insulates the unburned wood forming an insulating layer that slows down further combustion. Charring of wood can also protect non-combustible steel elements and therefore can achieve Fire Resistance Ratings (FRR). Industry testing has modeled charring rates as predictable functions of time, meaning that sacrificial char layers in beams and columns can be designed such that the reduced effective cross-section can effectively carry the structural load.

Technical Report No. 10

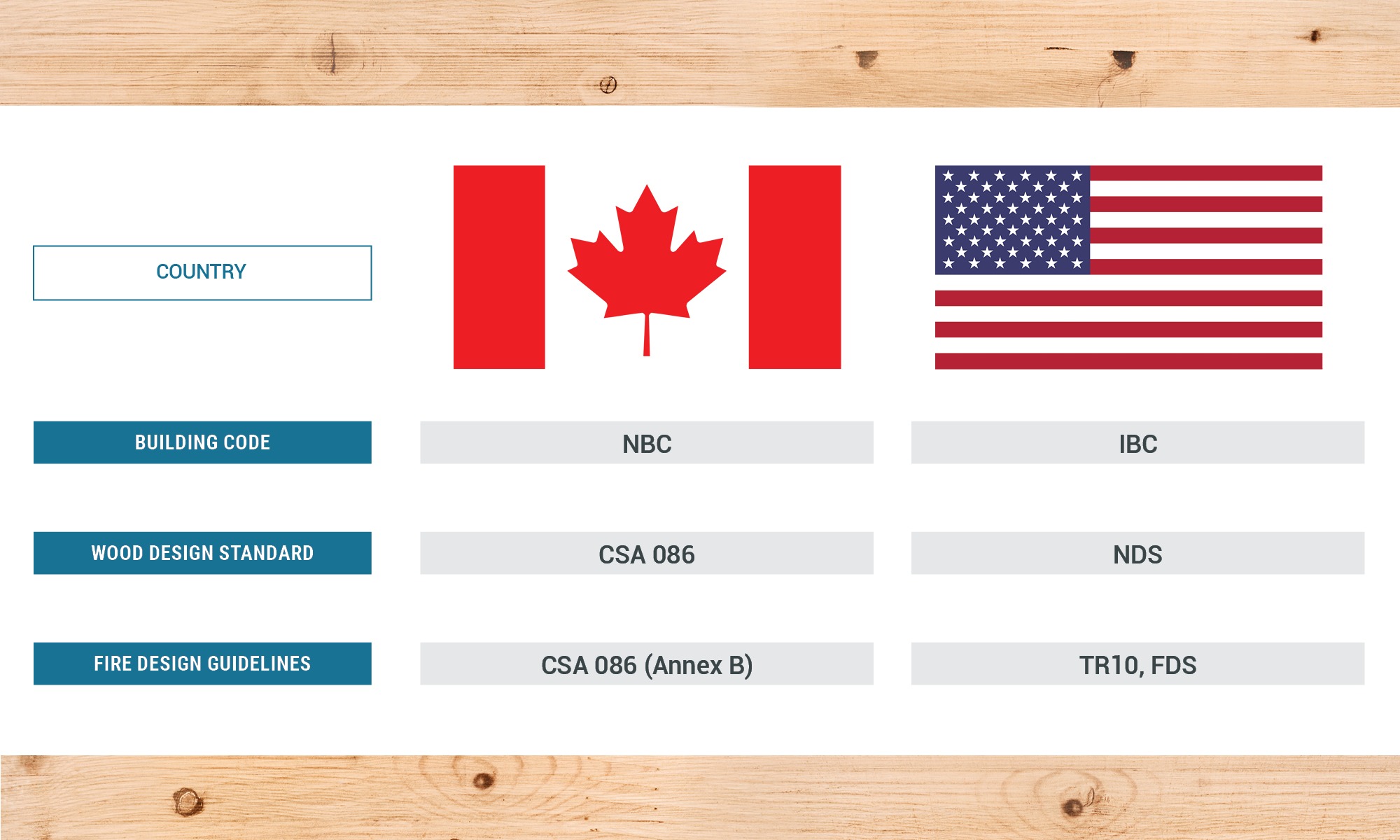

Technical Report No. 10 (TR 10), published by the American Wood Council, is technically applicable in the US, while Annex B of CSA 086, is employed to provide guidance on calculating fire resistance rating based on structural criteria in Canada.

Section 4.1.1 of the TR 10, 2021 outlines a method for calculating the char depth, a char, and effective char depth, a eff, for a given FRR.

As an example, a nominal char rate, in/hr [linear char rate based on 1-hour exposure], βn, of 1.5”/hr corresponds to a char depth (a char) of 1.5″, and an effective char depth (a eff) of 1.8″ for a 1-hour FRR. For structural calculations, section properties are calculated using dimensions which have been reduced for each surface exposed to fire. The dimensions are reduced by the effective char depth, a eff, which is 20% greater than the actual char depth, a char. The 20% increase accounts for strength and stiffness loss in the heated zone and rounding at corners.

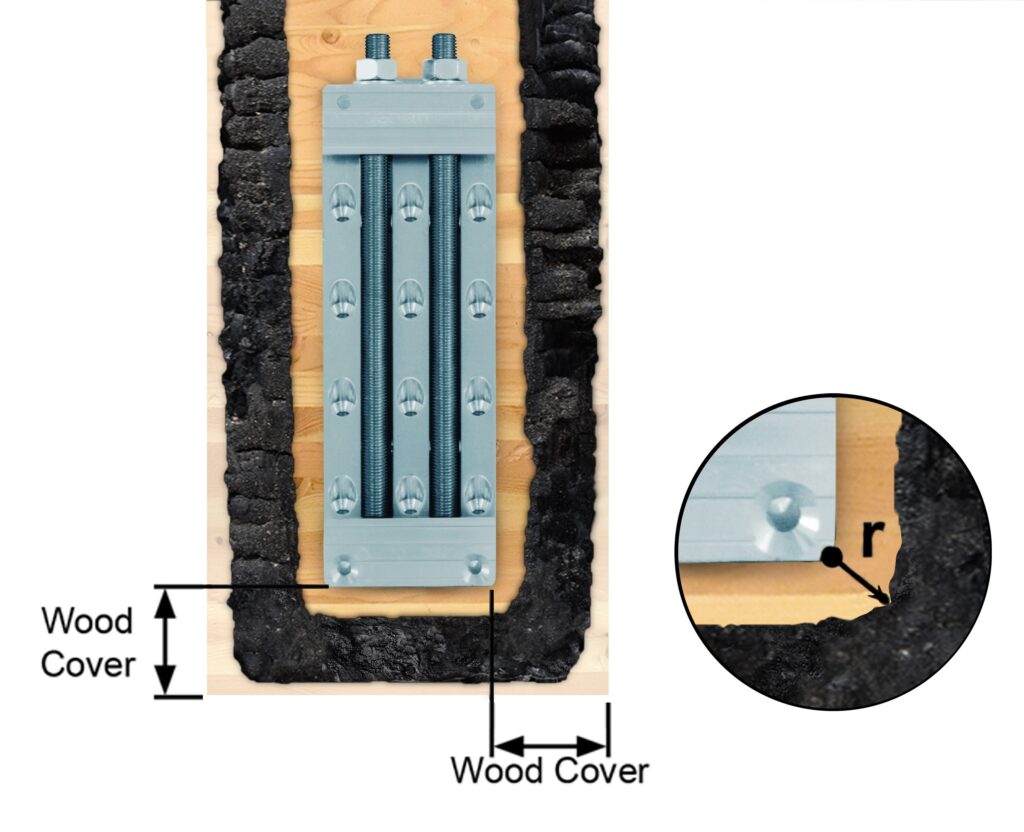

The minimum or maximum size of the gap between the two components at the connection point is not specified clearly in the current version of the TR-10. However, the Eurocode 5, states that the gap should not be larger than 3 mm. The penetration of ignition into gaps at ends of unbonded wood members due to char contraction shall be taken as twice the char depth, 2a char, while the thickness of wood cover required to provide thermal separation for bonded connections should be taken only as 1.14a char. Common bonding elements are including fire caulking, intumescent tape, glued wood, etc.

Corner Rounding Effect

During a fire event, structural members may be exposed to fire on more than one face, which will result in corners experiencing a faster charring rate. The unidirectional models used to estimate char layer thickness exclude the effect of fire exposure from multiple directions on a wood member. To account for increased charring at corners, corner rounding is considered in structural fire design. As shown in the figure below, the radius of the corner (r) illustrates the additional charring experienced and the increased cover requirements at corners.

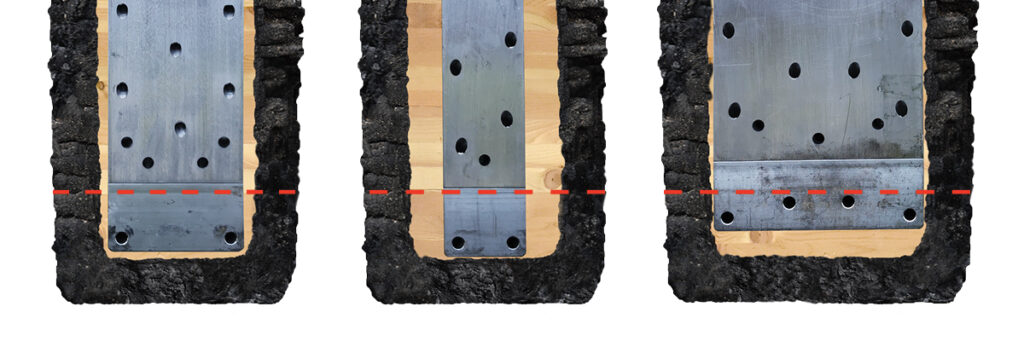

This corner rounding effect is especially important when designing concealed beam hanger connections. In the figures below, the undamaged wood represents the section of the beam that will be insulated from a fire event and will be protected by the charred layers. Following regular design requirements outlined in our connection design guides, the dashed red line represents the maximum distance from the bottom of the member cross-section, a sec max (see MTC’s Beam Hanger Design Guide), at which the connector may be installed. MTC Solutions beam hangers consider this requirement to avoid the use of reinforcing screws (perpendicular to grain splitting), and this is still an important detail in fire design. To achieve a proper fire-rated connection, the connector must fit inside this region of undamaged wood and the bottom of the connector must sit below this dashed red line.

Design Example

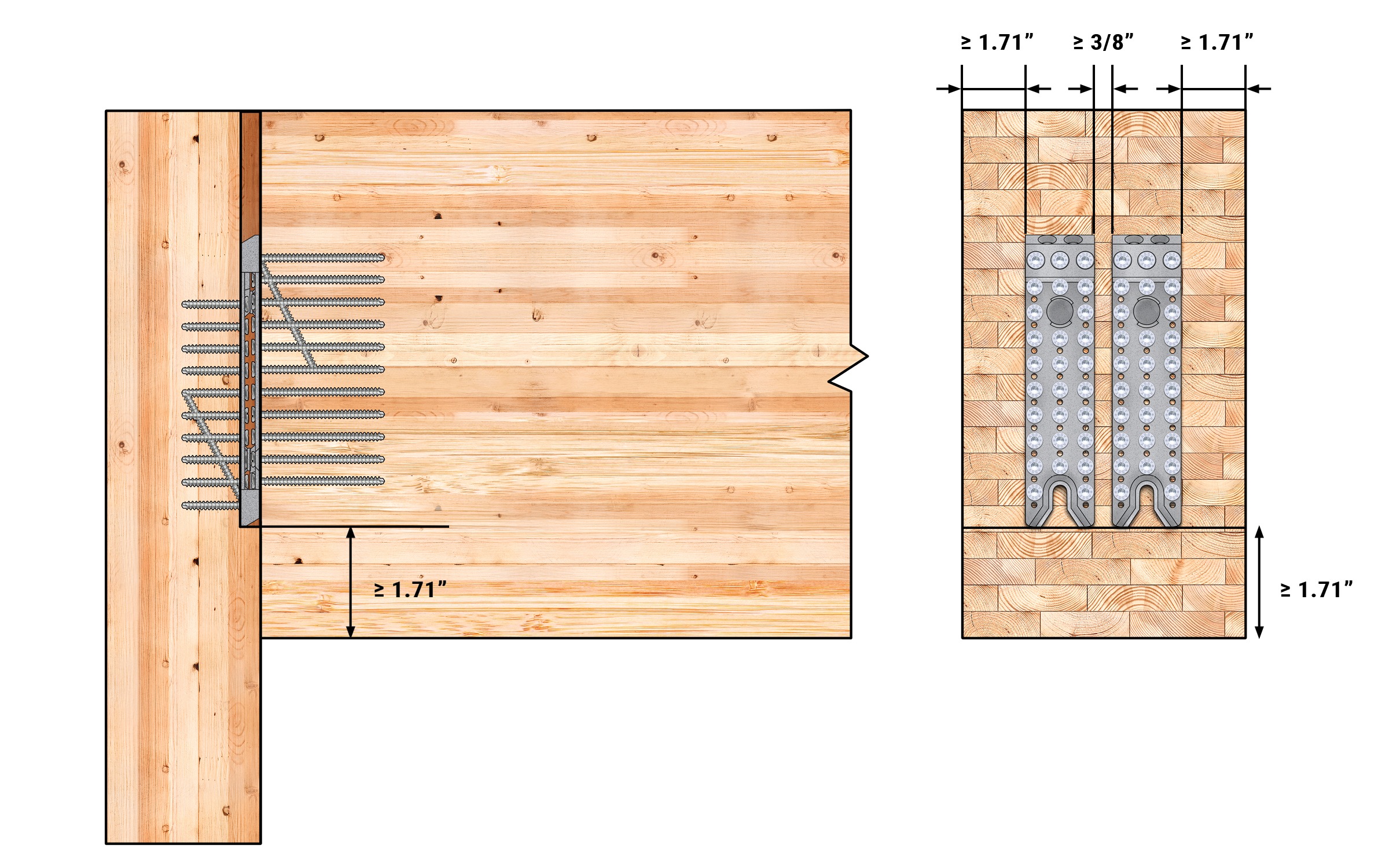

Let us assume a designer is working on a beam-to-column connection with a 10” x 27-5/6” beam carrying a shear reaction of 20.4 kips ASD while achieving a 1-hour fire-resistance rating. In accordance with the TR 10, bonded connections may be designed with the protective layer of wood of thickness 1.71” for 1-hour fire resistance requirement. On the 10” x 27-5/6” beam, the RICON S VS 390 x 80 easily meets the cover requirements outlined in the TR 10, leaving a minimum of 1.71” of cover on the sides and bottom of the connector.

For more information, MTC’s Beam Hanger Design Guide provides complete design tables to easily achieve concealed and fire-rated connections. The guide provides the minimum cross-section required to properly conceal the GIGANT, the RICON S VS and the MEGANT for 1-hour and 2-hour FRR. Moreover, the RICON S VS and the MEGANT were tested following ASTM standards and were awarded a 1.5-hour fire rating certification under a full-scale fully loaded test conducted at the South West Research Institute in San Antonio Texas.

If you have any questions, contact our Technical Support Team 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.