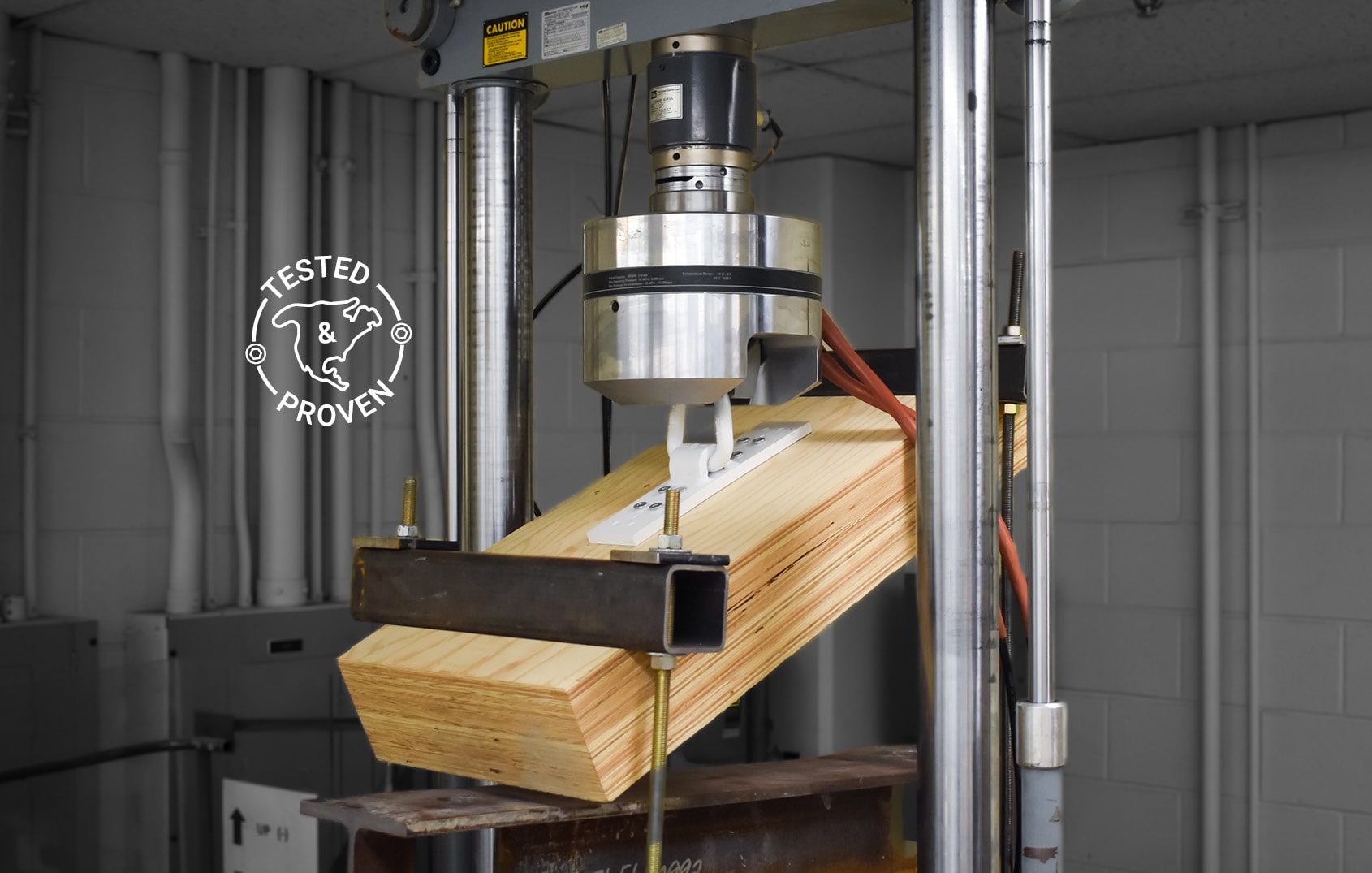

Tested and proven in North America, the MTC Solutions rigging devices are designed to handle engineered wood products of all sizes. All our rigging products meet safety standards for the Occupational Safety and Health Administration (OSHA) in the USA and the Infrastructure Health & Safety Association (IHSA) in Canada, providing peace of mind to both designers and builders in these two jurisdictions.

The MTC Solutions Rigging Design Guide offers general guidelines on the potential lifting capacities of the Yoke and Transport Anchor rigging systems used in combination with ICC-ES- and CCMC-approved ASSY® self-tapping screws (STSs). It provides rigging options for lifting most engineered wood products in North America, including cross-laminated timber (CLT) panels, mass plywood panels (MPPs), glue-laminated timber (glulam) beams, light-frame assemblies, and more! You can name it, we can lift it.

All MTC Solutions rigging devices meet the mandatory 5:1 safety factor and have been tested in CLT, glulam, and MPPs, all made from North American wood species. This follows safety standards required by OSHA, stipulated in Clause 1926.753.(e)(2), as well as Canadian standards such as IHSA and WorkSafeBC.

The Rigging Design Guide is organized with the rigging planning process in mind for a streamlined experience. Starting with determining the force per anchor (F) based on the weight of the element and the rigging conditions, it then helps you select the appropriate rigging system for the wood product you will be lifting. Following this, the guide provides installation instructions and checks for those working on-site. Check out our two-minute video walking you through this step-by-step process.

What’s more, our rigging systems are reusable, and with several sets on-site you can easily rotate through them as you unload and lift your prefabricated elements, resulting in further efficiency.

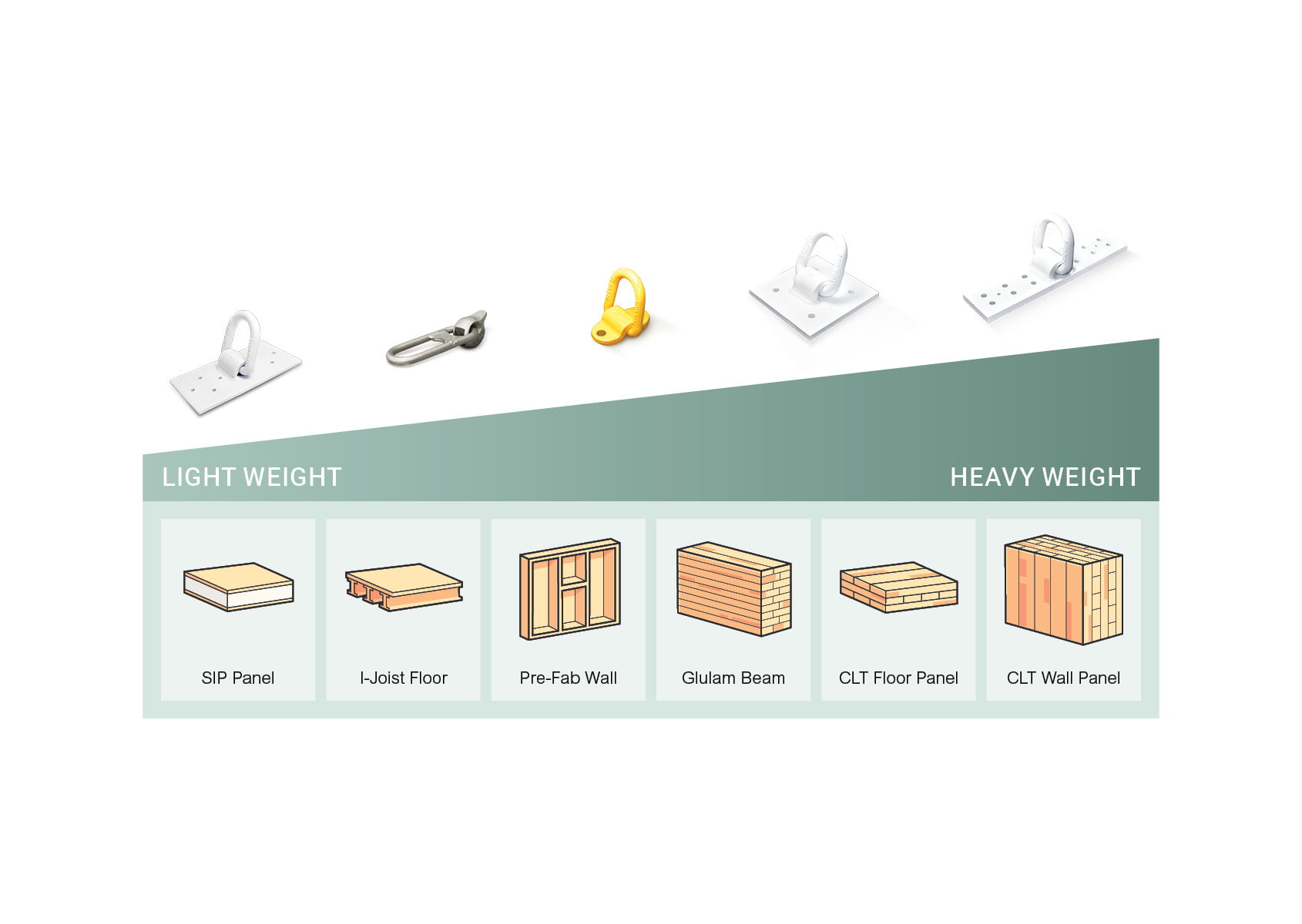

Our rigging devices are capable of lifting a wide range of engineered wood products. These include light-frame assemblies such as structural insulated roof panels and prefabricated I-joist floors and stud walls; mass timber panels such as CLT and MPPs in floor panel lifting and wall panel tilting; glulam beams; and log members. The lineup of rigging options we provide can handle virtually any wood products your project demands.

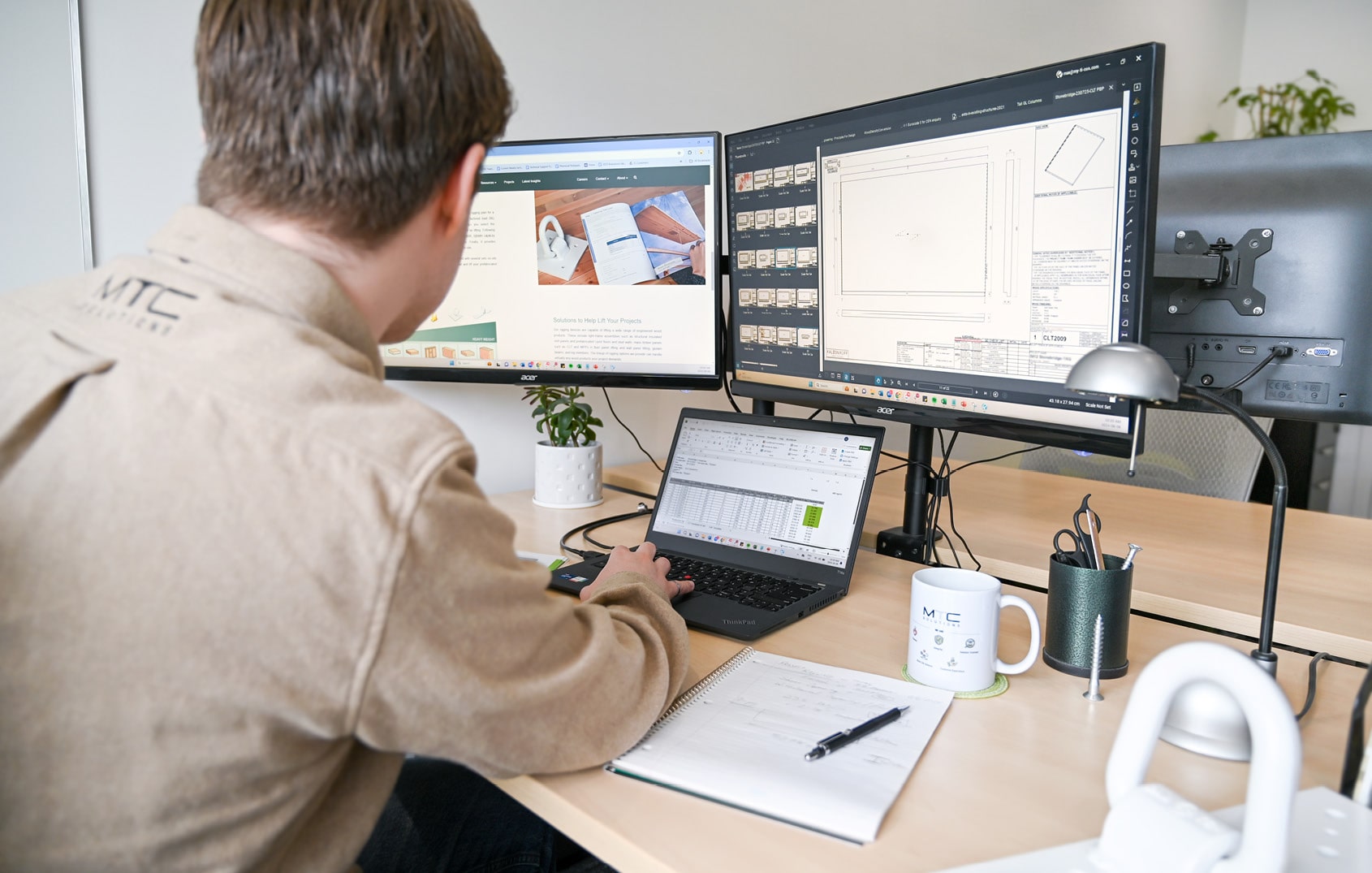

Our support goes beyond supplying mass timber hardware and documents. Our Technical Support Team is also available to answer any questions you may have about using our rigging solutions.

Share your production schedule for your mass timber elements, we’ll run weight calculations to ensure that the required factors of safety used in rigging are met with our yokes. One of our tech advisors will provide you with a tailored rigging solution and the associated hardware takeoff for your specific project, all with quick turnaround times! All that’s left is to seek approval from your rigging engineer.

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.