Screw crosses, known for their bidirectional resistance, play a pivotal role in transferring lateral forces, especially under reverse loading conditions. This note explores essential considerations to ensure their optimal performance.

Approximately 3-minute read.

Use of inclined self-tapping screws (STSs)—STSs inserted at a non-zero and non-perpendicular angle relative to the grain direction—is a common practice for creating connections with high stiffness and high load-bearing capacity. STSs are readily available off the shelf and can be installed using standard handheld tools. Arranging inclined screws in parallel offers a notable advantage in withstanding unidirectional loads. In this scenario, the screws are primarily loaded in tension while undergoing minimal bending behavior.

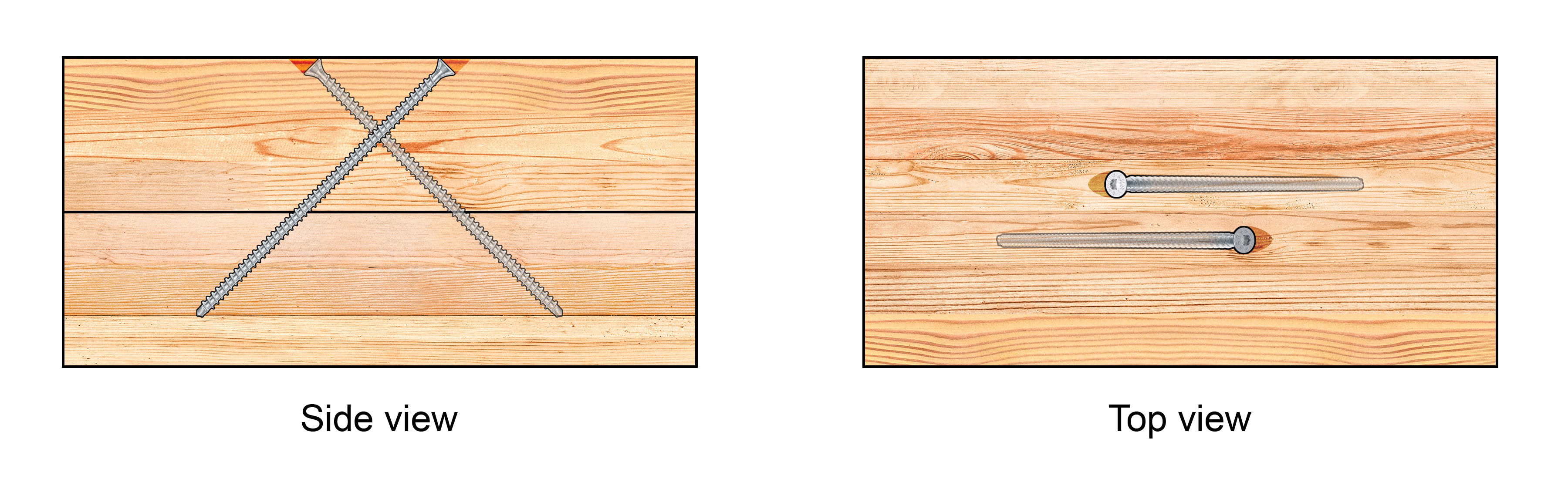

To transfer reverse lateral loads, that is, cyclic bidirectional loads, a favored approach involves employing pairs of inclined screws. Each pair, referred to as a screw cross, comprises two screws inserted at identical angles (typically 45°) relative to the shear plane. These screws are symmetrically positioned but oriented in opposite directions. Within each cross, one screw predominantly bears tensile loading, while the other screw primarily undergoes compressive loading.

Figure 1. Illustration of a screw cross

Attaining optimal performance with screw crosses requires attention to some factors. It is imperative to maintain a minimum offset of 1.5 times the nominal screw diameter between the two constituent screws to prevent any potential interference. Moreover, for consistent angle placement, it is advisable to predrill short pilot holes during installation, particularly when working with screws longer than 10 inches. For detailed predrilling guidance and best practices, along with methods for calculating resistance, please refer to the Structural Screw Catalog and relevant articles provided by MTC Solutions below:

Screw crosses excel in connections between cross-laminated timber panels and beams that experience frequent bidirectional movement and feature high design loads. However, in seismically active regions, their high stiffness may limit their suitability for connections (e.g., lap joints) requiring high-ductility performance. Notably, the ANSI/AWC 2021 Special Design Provisions for Wind and Seismic does not cover the application of inclined screws in diaphragm connections, as they may not achieve the required yield modes involving plastic hinge development. In regions with lower seismic activity, the use of screw crosses in diaphragm connections generally presents no significant concerns.

While screw crosses offer an appealing solution for transferring bidirectional loads and delivering high stiffness, it is vital to consider various factors to ensure their effectiveness. For more information and design guidance, please contact our Technical Support Team. 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.