Modern mass timber construction has gained increasing prestige in recent years. Projects have become more complex, combining traditional designs with modern connections engineering. The growth of the mass timber industry has been strengthened by the development of innovative connection technologies that amplify its benefits with in-shop pre-installation, shorter construction time, fewer power tools, and reduced risks of injuries or mis-installation.

The MEGANT beam hanger systems provide such innovative pre-engineered solutions. They are high capacity connecting systems, fire rated & tested in multiple scenarios, that offer an architecturally appealing & fully concealed solution. The installation of MEGANT beam hanger systems must be completed in accordance with engineering specifications to assure the desired structural performance. This blog post provides guidance for installation tools.

Approximately 8-minute read.

How to Accurately Install MEGANTs?

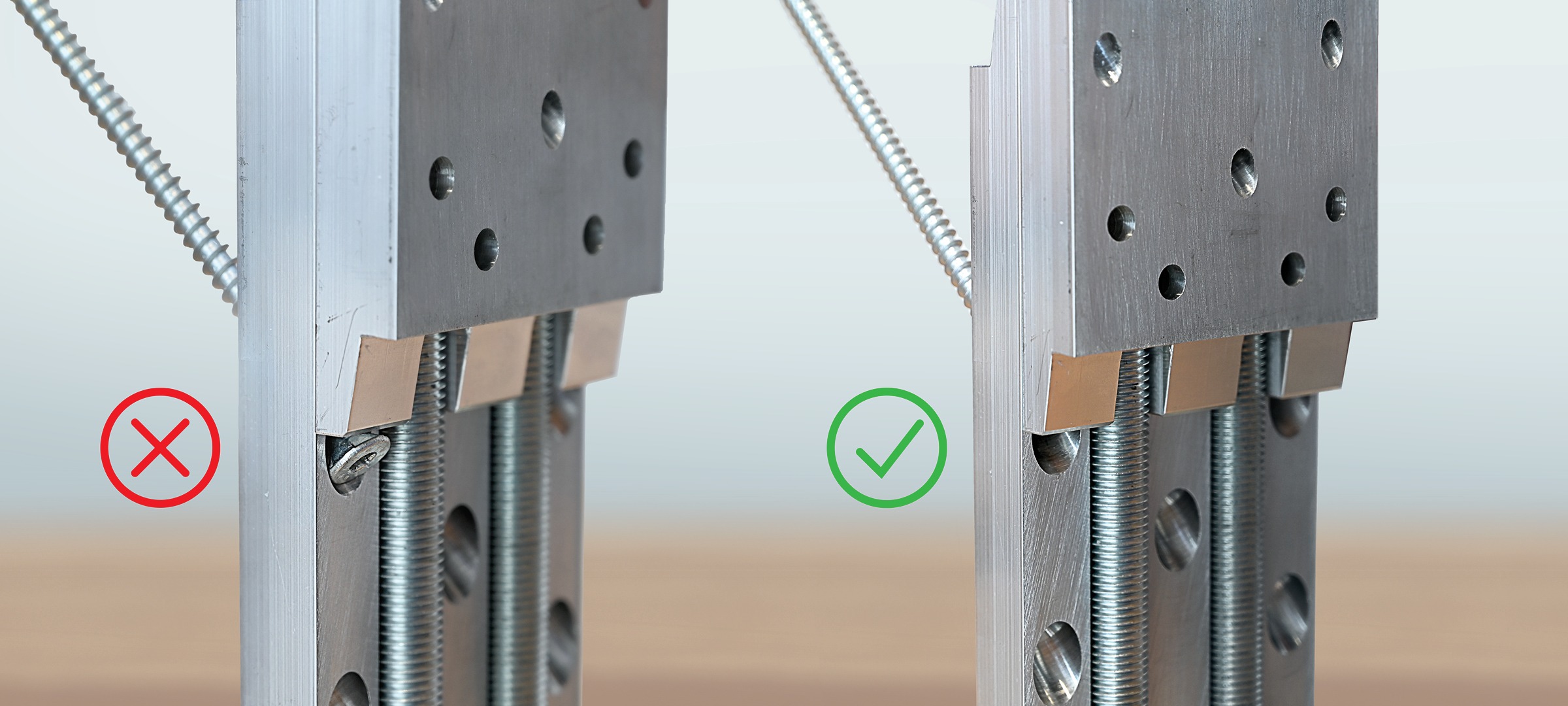

The MEGANT beam hanger systems are installed with a combination of 45⁰ & 90⁰ angle fasteners (ASSY VG CSK 5/16’’ x 6-1/4” [8 x 160 mm] ). Installation tolerances for the screw in angles are most often acceptable with a +/-3⁰ angle variation. Deviations exceeding this approximate tolerance boundary shall be verified by a qualified design professional.

To obtain the desired performance, all MEGANT fasteners must be seated appropriately into the machined countersunk seat, the screw heads must not sit proud or be over torqued. In some cases, shop installation of the MEGANT connection system is made more challenging since assisting tools and jigs are not used for accurate and easy screw install.

The MTC Pre-drilling Jig

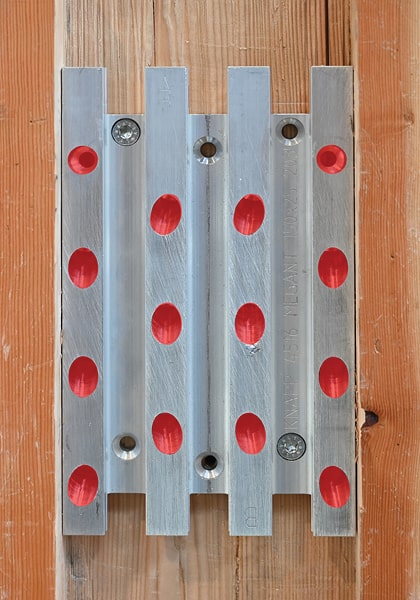

The MTC Pre-Drilling Jigs are a simple proven accessory that are specifically designed to allow for precise pre-drilling for the MEGANT’s ASSY VG CSK fasteners. Available in 5/16” [8 mm], our Jigs are readily compatible with the MEGANT beam hanger system, with shoulder geometry and tight tolerance at the tip to ensure rapid and automatic positioning and alignment with minimal play in the receiving hole. This supports fast and guided pre-drilling for the inclined screws characteristic of the MEGANT, resulting in a consistent, cost-efficient, and precise fastener installation.

Please note that it is essential to use the correct drill bit diameters to ensure that the fastener capacities are not adversely affected, and the load limits remain as intended for the MEGANT assembly. The inner diameter of our Jigs [ d ] accommodate standard imperial and metric drill bit diameters recommended for pre-drilling (3/16″ [5mm] for MEGANT fasteners). Pre-drilling requirements may differ in species of higher specific gravity, with pilot hole depths typically ranging from 3/4″ to 3”, but should meet any additional requirements specified by your project’s design professional.

Pre-drilling offers several benefits, including a faster wood bite and installation, reduction in installation torque and screw breakage hazards, and decrease in screw wandering and deviation, ensuring proper seating of fastener heads in receiving holes and minimizing the potential for screw collisions. If you would like to know more, refer to our blog post on predrilling & pilot holes.

Fasteners installation with fully housed MEGANTs?

MEGANT beam hanger systems can be fully concealed, offering architecturally appealing & fire rated connections, with the use of various housing options in mass timber members. Alternate installation tools may be required, however, depending on the housing configuration and positioning selected by the design teams. Drill chucks or drill motors may interfere with the housing edges, hindering precise and proper screw install. The collision of drill parts and wood can be easily avoided using common bit extensions available from your local hardware store.

In a Pinch? How to make a Custom Bit Extender

A suitable bit extension can be assembled from common 1/4” torx bits, a 1/4” extension and a 1/4” drive socket. We do however, recommend the use of the RW 40 bit instead of common 1/4” torx bits, for an effective installation of the MEGANT’s VG CSK 5/16’’ x 6-1/4” [8 x 160 mm]. Fastener installation into housed MEGANT connectors is now possible without collision of power tool body or chuck against the wood.

If you are in the early stages of involvement in Mass Timber and the installation of connection elements is in your scope of work, we highly recommend investing in the common basic tools we have highlighted in this blog post.

If you would like to learn more on how to install MTC pre-engineered connections, download our detailed Beam Hanger Design Guide. For any questions, contact our Technical Service Team. 😉

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.