Mass Timber is increasingly being used in larger scale commercial construction on an institutional, industrial, and residential mid- to high-rise level. With this comes the need for an efficient building design, and its connection technology is no exception. Besides the desire to reduce cost and construction time, we must also obtain the desired building performance while maintaining a sustainable forward-thinking mindset throughout the process. Safety is always a high priority when it comes to connection design, however, using excessive amounts of fasteners can trigger the exact opposite since a connection may not behave as intended.

In mass timber framing systems, the most common connection types are:

Understanding the different failure modes of structural self-tapping screws (STS) in these configurations is essential for any designer working on a mass timber project. In the last part of this blog series, we will investigate the failure modes and yielding mechanisms for lateral connections with fasteners loaded in tension at a 45⁰ angle in both steel-to-wood and wood-to-wood configurations.

Approximately 3-min read

Understanding Mass Timber Connections Behavior

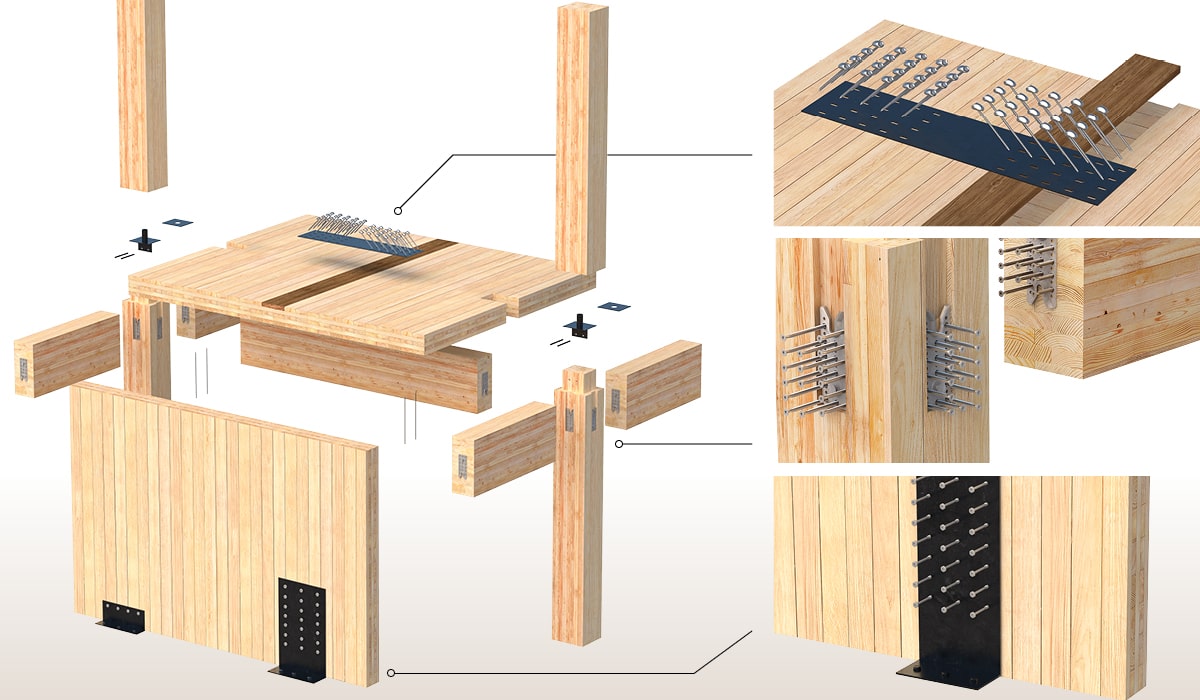

The first step in understanding mass timber’s connection behavior is understanding how fasteners behave in connecting systems, but why is that? Looking below, we have a basic overview of where fastening technology for connections can be used. In fact, they are currently an essential element in all types of designed solutions: posts and beams, wall and floor panels, straps, and plates, in wood-to-wood, and steel-to-wood configurations.

Please note that the below-mentioned behaviors are for monotonic loading only. Under dynamic conditions, fasteners behavior and failure modes may vary.

Lateral Connections with Fasteners Loaded in Tension at a 45⁰ Angle

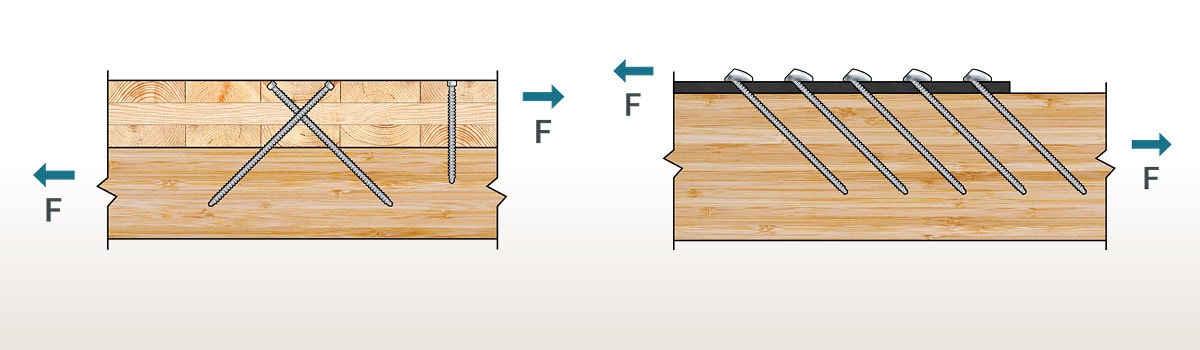

Connections with fasteners arranged at 45 degrees can essentially consist of three different main configurations: A cross wise arrangement, a parallel inclined arrangement with sufficient main member embedding to produce tension failure of the screw, and main member embedding to produce withdrawal failure of the screw (variations of either are also possible). Each configuration or combination thereof can produce different connection behaviours. Consideration shall be given to possible brittle wood-related failure modes such as plug tear out/net tension, group tear out, perpendicular-to-grain tension and longitudinal shear.

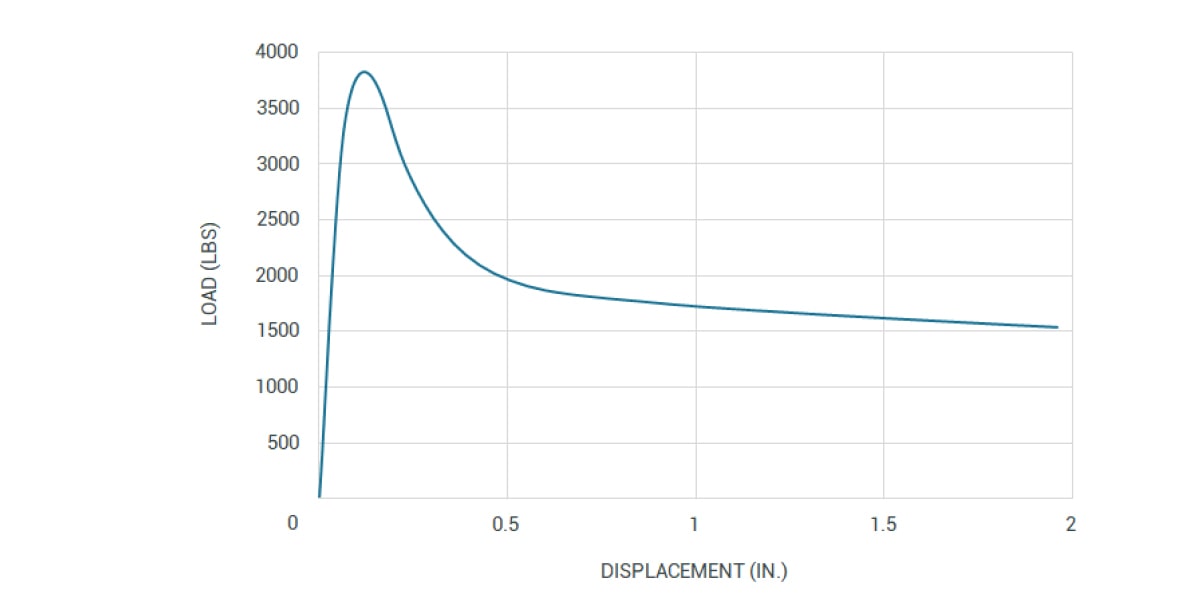

The most desirable connection configuration in terms of default ductility is shown in the idealised graph below. A properly detailed wood-to-wood connection with cross wise inclined 45° full thread fasteners would typically yield a predictable linear initial slope with a sharp load drop where a ductile plateau is held by the shear capacity of the cross wise fasteners after withdrawal or push out failure occurs. One other benefit of this connection worth mentioning is that it can transmit loads equally in both directions.

In Summary

Withdrawal-based connection configurations with force components in axial direction of the fastener exhibit a typically predictable linear force and displacement relationship resulting in higher stiffness and higher capacity. Shear connection configurations where force components are perpendicular to the fastener axis generally exhibit lower stiffness and lower capacity.

Complementary blogs about lateral connections with fasteners loaded in shear and axial connections with fasteners loaded in tension parallel to their axis will provide the necessary information to understand standard mass timber connections’ behavior. For more information on how to design these connections with MTC structural fasteners, download & read our Structural Screw Catalog.

If you have any further questions, please contact our Technical Service Team 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.