With the increasing use of mass timber in mid and high-rise construction, there is a growing need for design guidance on connecting systems that use structural Self-Tapping Screws (STS). Understanding connection behavior is critical in promoting the competitiveness of a structure, and mass timber is no exception.

In addition to reducing costs and construction time for a project, reaching the desired performance while reducing the amount of materials to install will contribute to a sustainable forward thinking that we embrace at MTC Solutions. On a side note, it is worth mentioning that using an excessive number of fasteners, even though it could appear at first to create additional safety, may change the behavior and capacity of a system (and vice versa).

In mass timber framing systems, the most common connection types are:

Understanding the different failure modes of structural self-tapping screws (STS) in these configurations is essential for any designer working on a mass timber project. In the first part of this blog series, we will investigate the failure modes and yielding mechanisms for lateral connections with fasteners loaded in shear.

Approximately 6-min read

Understanding Mass Timber Connections Behavior

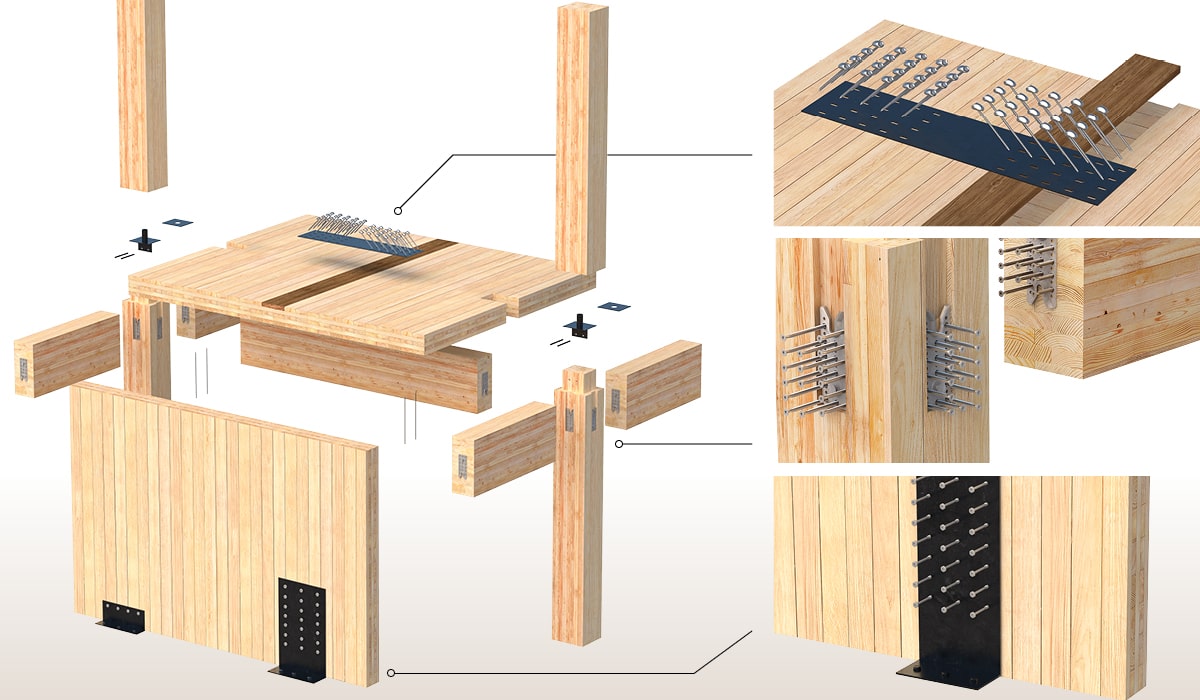

The first step in understanding mass timber’s connection behavior is understanding how fasteners behave in connecting systems, but why is that? Looking below, we have a basic overview of where fastening technology for connections can be used. In fact, they are currently an essential element in all types of designed solutions: posts and beams, wall and floor panels, straps, and plates, in wood-to-wood, and steel-to-wood configurations.

Please note that the below-mentioned behaviors are for monotonic loading only. Under dynamic conditions, fastener behavior and failure modes may vary.

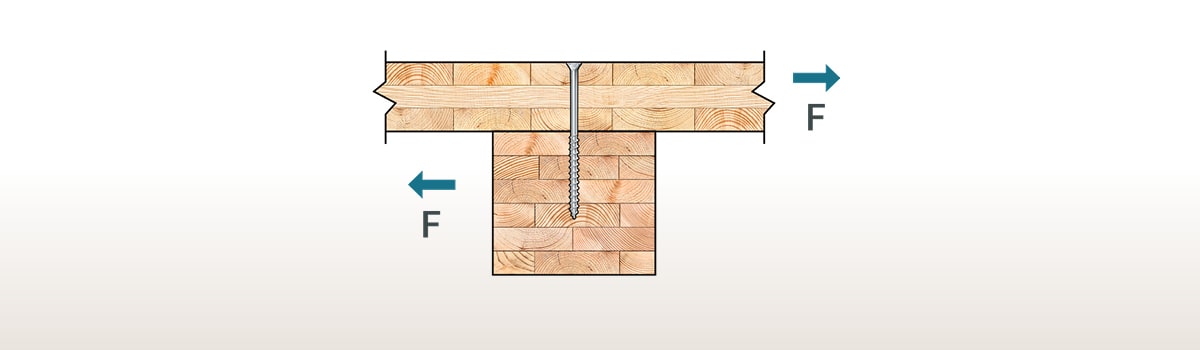

Lateral Connections with Fasteners Loaded in Shear in Wood-to-Wood Configurations

In such loading scenarios, the fastener’s yielding process occurs in several steps. When the load is first transferred to the fastener, bearing against the wood will initiate wood crushing. The crushed wood and the associated cavity allow fastener bending where the bending yield strength eventually becomes a controlling factor. Provided that the STS’s steel shall have the ability to deform significantly before breaking, we obtain the much-desired ductile performance.

Further factors influencing the ductility of a connection can be found in the specific gravity and the sensitivity of the timber species to splitting. Species such as Douglas Fir and Fir are typically prone to splitting and may contribute to a connection not behaving as desired if the connection detailing does not account for the specific properties of the species. Among other factors, thread length, thread length embedded in main and side members, as well as head geometry and head diameter can influence connection behaviour to become more brittle or more ductile. For instance, a fastener with a partial thread and a head pull-in promoting shape may produce more ductile results by default as the head will crush into the wood fibre (head pull-in) given a certain deformation. This can then produce a typical ductile load deformation response.

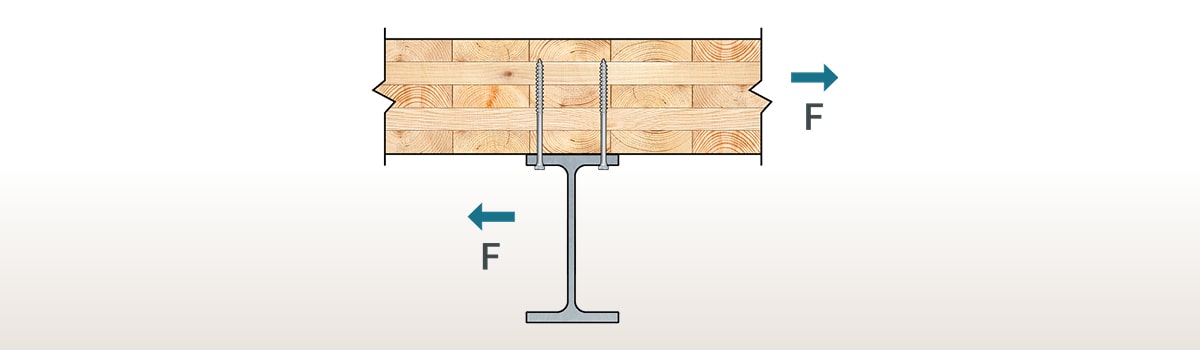

Lateral Connections with Fasteners Loaded in Shear in Steel-to-Wood Configurations

In configurations where the side member is a steel plate, connection ductility will rely on the fasteners’ ability to deform without breaking, as fastener heads cannot “crush” their way into steel material. The ductile response will solely be produced by fastener shank deformation and the ability of the fastener to deform under load without breaking.

By default, in the NDS 2018 edition and CSA-086, fasteners in shear configuration are expected to exhibit a ductile behavior considering the connection is detailed properly. This applies especially in Cross Laminated Timber (CLT) where brittle splitting can generally be avoided, given that proper connection geometry requirements are respected. CLT can however produce other, less obvious brittle failure modes such as block shear, plug shear and rolling shear failure, most often related to not accurately detailed connection geometry. However, both design standards do not regulate other critical properties around the design parameters of the bending yield strength [Fyb] values, thus, leaving room for potential unanticipated connection performances. Recently conducted research seems to support this assumption (See Hugh C. Merryday et al “Pushout Tests On Steel-Timber Connections Using Self-Tapping Screws).

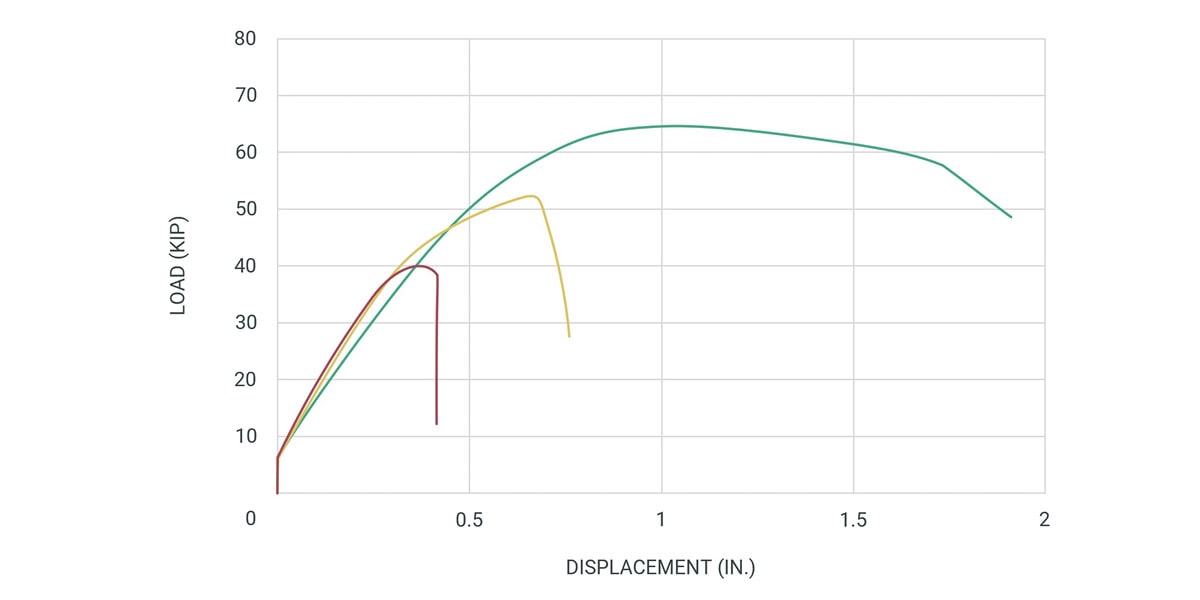

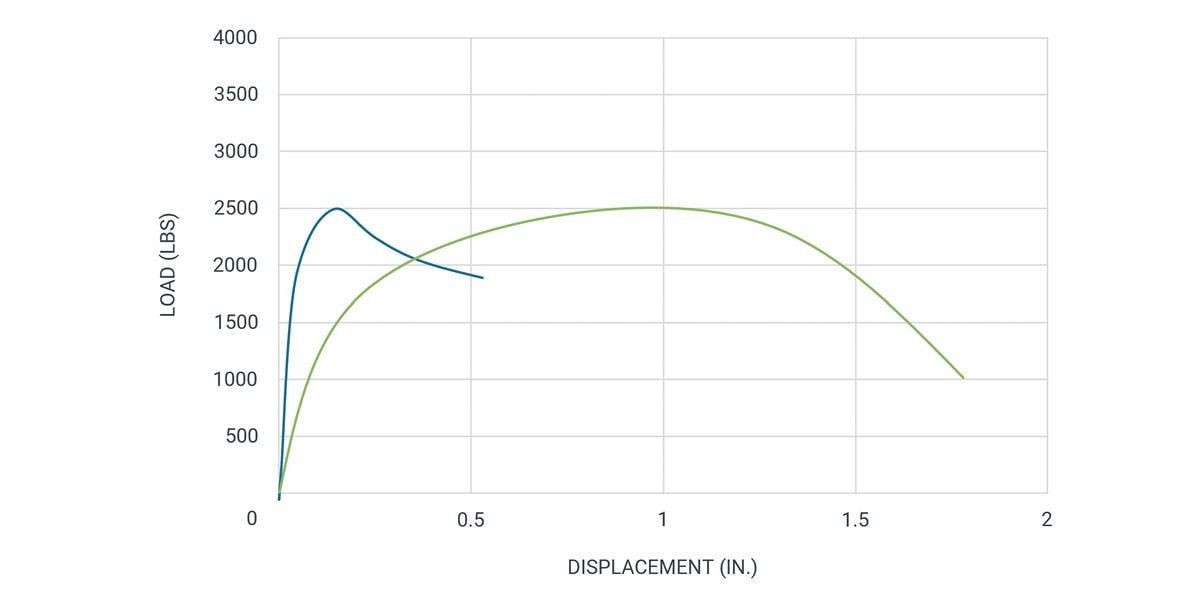

The above idealized load displacement curves, plotted from MTC Solutions’ tests of comparable, equal diameter threaded fasteners in steel-to-wood connections, showcase different yield mechanisms. The graphs exhibit failure modes from rather brittle (red curve) to typical ductile (green curve). The yielding mechanisms obtained appear to be influenced by a variety of typical factors which are addressed in applicable design standards while other, less typical factors are not addressed in typical design standards.

Manufacturing Process, Ductility and Bending Yield Strength Correlation

It is worth mentioning that the STS manufacturing process varies based on the selected manufacturer and distributor. Each manufacturer may calibrate certain boundary conditions of the process to obtain specific desirables for fastener strength. Increased strength, however, does not always correlate to the desired ductility which can be seen in the tests performed. An increase in strength properties may result in a reduction of the ability of a fastener to deform under loading and hence influence the overall predicted connection performance. As a rule of thumb, within a set of given boundary conditions, one can assume that as the bending yield strength value increases, the shear capacity increases and the ability to deform under load decreases. A good comparison we use is: “Ductility is like a currency”; In many ways, we must “pay” with ductility to “buy” stiffness, capacity, and strength.

In most cases design codes would estimate a higher capacity for the fastener with an increased bending yield strength while defaulting to a “ductile” performance given a certain embedding and connection geometry. However, under the consideration of results obtained from testing, fasteners with an increased bending yield strength appear to have ultimately not demonstrated this estimated higher capacity.

The figure below supports findings presented in the load displacement curve in this post after the specimens were disassembled. One can identify wood crushing and the exhibiting of failure modes III and IV for the fasteners with a rather lower bending yield strength.

At this time, we can not fully assume that existing design standards are suitable to accurately predict performances under all connection geometries and specifics of different fastener strength properties encountered in mass timber. Given the wealth of options available, we always encourage you to reach out to your trusted supplier and confirm design intentions as early as possible in your project scope. Most often the suppliers are experts on their products and can direct you in decision making and help you understand which choice to make.

To Summarize

Fasteners acting in shear can produce a variety of different results. Fasteners with a lower bending yield strength and great toughness appear to produce more consistent ductile results, while fasteners of greater bending yield strength with less toughness appear to fail in a more brittle fashion, hosting significantly less deformation ability. While there seems to be appropriate safety factors under static design considerations, current design code models can not be assumed to entirely accurately predict fastener performances used in a variety of typical Mass Timber Connections.

Complementary blogs about axial connections with fasteners loaded in tension parallel to their axis and lateral connections with fasteners loaded in tension at a 45⁰ angle will provide the necessary information to understand standard mass timber connections’ behavior. For more information on how to design these connections with MTC structural fasteners, you can also download & read our Structural Screw Catalog.

If you have any further questions, please contact our Technical Service Team 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.