Mass Timber is increasingly being used in larger scale commercial construction on an institutional, industrial, and residential mid to high-rise level. With this comes the need for an efficient building design, and its connection technology is no exception. Besides the desire to reduce cost and construction time, we must also obtain the desired building performance while maintaining a sustainable forward-thinking mindset throughout the process. Safety is always a high priority when it comes to connection design, however, using excessive amounts of fasteners can trigger the exact opposite since a connection may not behave the way we intent it to behave.

In mass timber framing systems, the most common connection types are:

Understanding the different failure modes of structural self-tapping screws (STS) in these configurations is essential for any designer working on a mass timber project. In the second part of this blog series, we will investigate the failure modes and yielding mechanisms for axial connections with fasteners loaded in tension parallel to their axis.

Approximately 4-min read

Understanding Mass Timber Connections Behavior

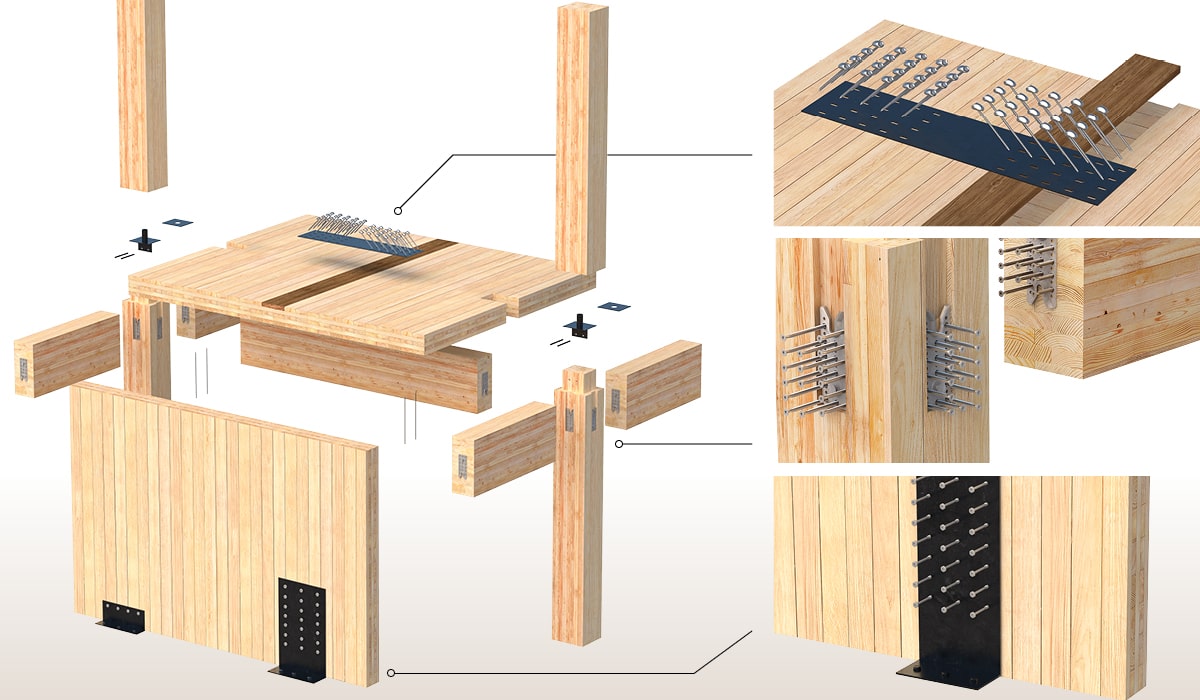

The first step in understanding mass timber’s connection behavior is understanding how fasteners behave in connecting systems, but why is that? Looking below, we have a basic overview of where fastening technology for connections can be used. In fact, they are currently an essential element in all types of designed solutions: posts and beams, wall and floor panels, straps, plates, in wood-to-wood, and steel-to-wood configurations.

Please note that the below-mentioned behaviors are applicable for monotonic loading only. Under cyclic conditions, fasteners behavior and failure modes may vary.

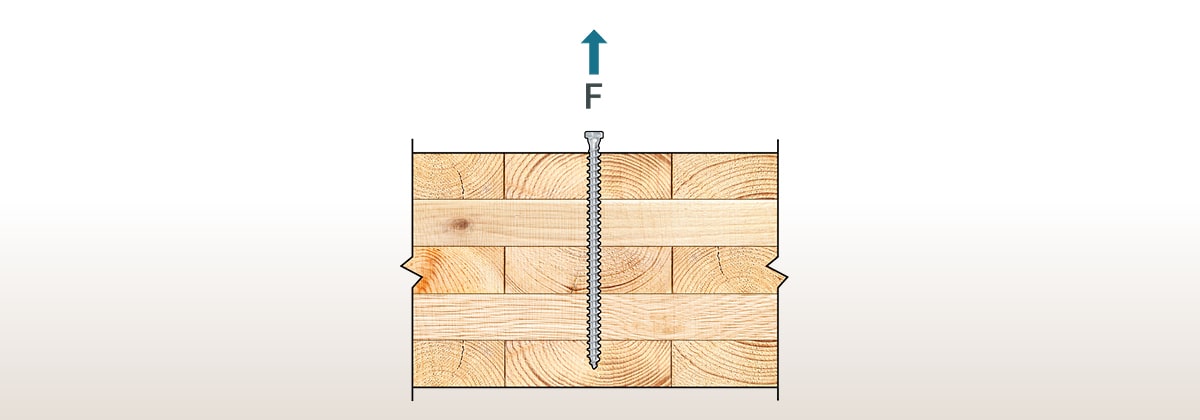

Axial Connections with Fasteners Loaded in Tension Parallel to Their Axis

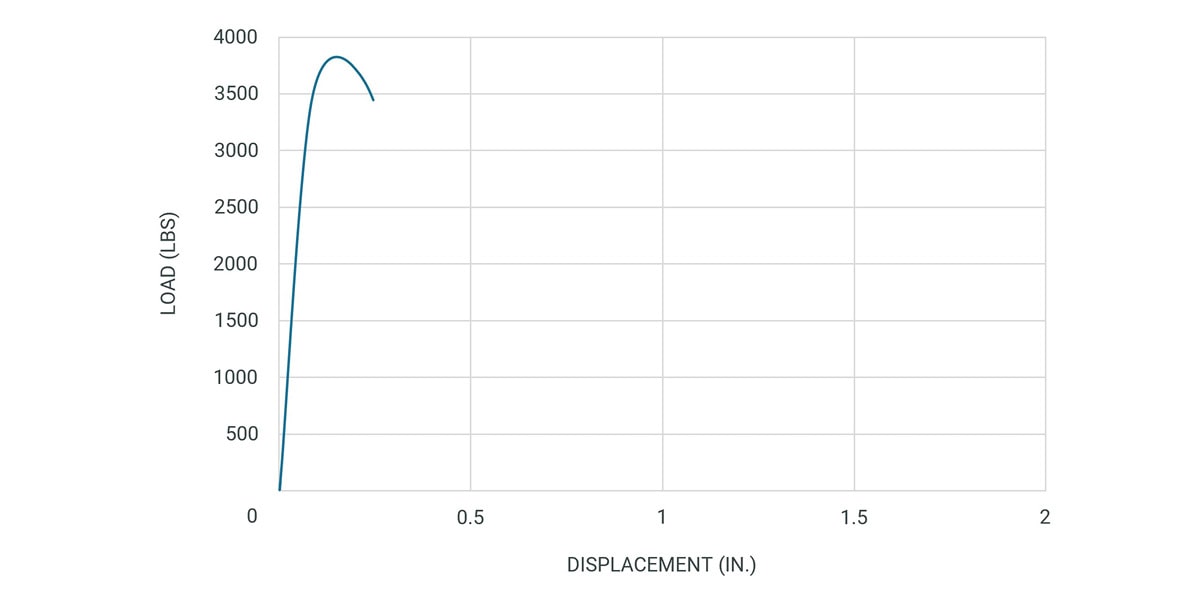

In this configuration, with respective embedding, the failure modes tend to be typical and predictable. The load displacement curve below showcases a steep linear line with limited yielding until failure in withdrawal or in steel tension occurs. This failure can typically be classified as rather brittle and occurs with limited plateau once the peak resistance is reached. These fastener arrangements are great for connections where limited deformation is desired.

The withdrawal resistance of a fastener is a function of

Where the fastener tensile resistance forms the upper limit of the withdrawal resistance.

Besides the withdrawal failure, axial connections with the fastener loaded parallel to their axis may also yield wood-related failure modes with non consistent load path, such as net tension, perpendicular-to-grain splitting, and various related wood group failures. Consistent load path design is essential for this type of connection.

In MTC’s tests, the typically observed Coefficient of Variation (COV) related to steel tension failure of the wood screws was around 1% while related typical COVs for withdrawal resistance failures were approximately 12% depending on the actual thread embedding depth.

Current design codes are not yet calibrated on all aspects for mass timber design, and one must accordingly expect irregularities. Improving codes and standards so that connection technology can be applied efficiently is a critical part in achieving a more sustainable mass timber building and design culture.

Complementary blogs about lateral connections with fasteners loaded in shear and lateral connections with fasteners loaded in tension at a 45⁰ angle will provide the necessary information to understand standard mass timber connections’ behavior. For more information on how to design these connections with MTC structural fasteners, you can also download & read our Structural Screw Catalog.

If you have any further questions, please contact our Technical Service Team 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.