Beam hangers provide versatile options for connecting mass timber elements. This white paper provides information on priorities for designing and detailing beam hanger connections. Placement of the beam hanger merits careful consideration, as it can influence the need for additional reinforcement in connections as well as their fire resistance and other structural properties. Techniques to minimize supplemental reinforcement, relevant brittle wood failure modes to consider, and tips for efficient design are included.

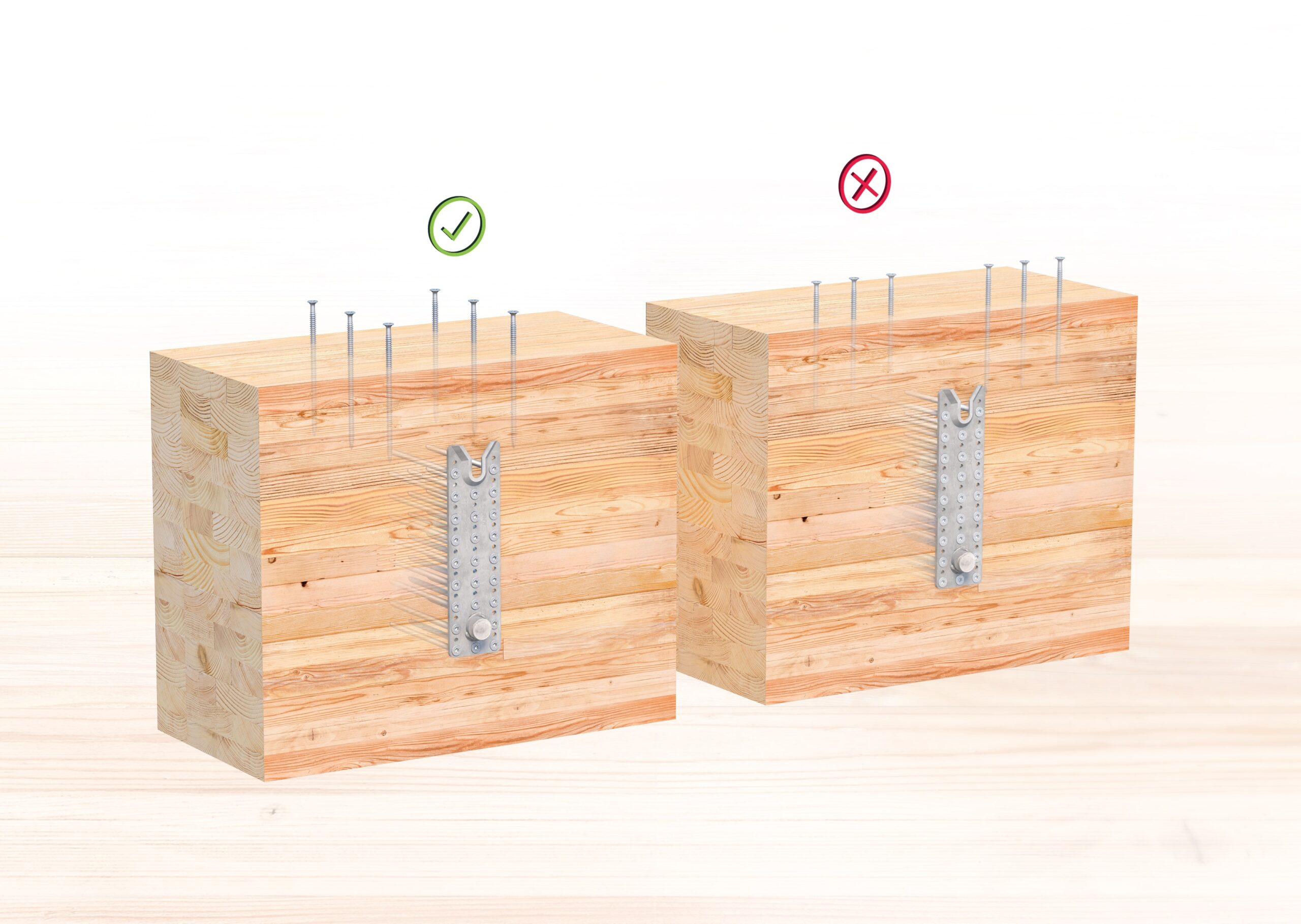

It is preferable to minimize the need for supplemental reinforcement around beam hangers to simplify connection detailing; however, project demands sometimes make reinforcement necessary. For such instances, best practice recommendations for the location of self-tapping screws (STSs) are included. Guidance on installing reinforcing screws, preventing fastener collision, and maximizing fastener efficiency is also provided.

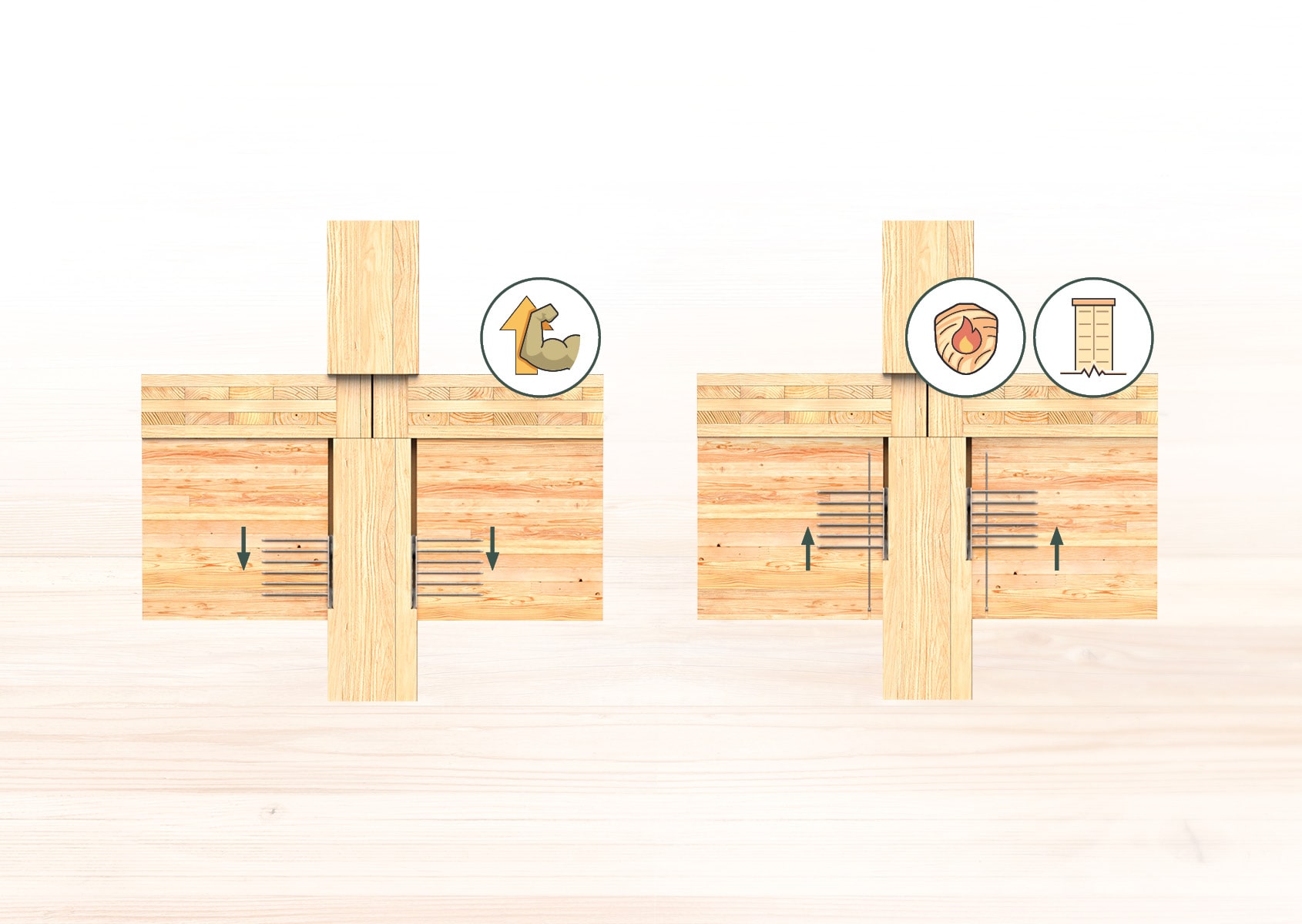

When using beam hanger connections, structural demands from gravity and lateral loads, fire resistance requirements, and architectural needs demand careful balancing from designers. Beam hangers connect a primary (supporting) member to a secondary (supported) member (i.e., a beam), and their placement with respect to the depth of the secondary member can impact the performance of the connection. Placing the hanger lower in the beam can help reduce its propensity for fracture at its end and the need for supplemental reinforcement, while placing the hanger higher in the beam offers enhanced fire resistance and seismic performance.

Brittle failure modes should always be evaluated for any multi-fastener connection, but current design standards do not always provide clear guidance on how to do so. In beam hanger connections, two primary brittle failure modes are of interest: tension-induced perpendicular-to-grain splitting in the side of primary members and beam-end fracture due to cross-grain tension. Beam-end fracture can occur in beams with a physical notch at the bearing point, or if the relative height of the connection allows for the development of a “virtual notch” in the secondary member. The use of STSs as reinforcement can help reduce the potential for splitting due to the cross-grain tension developed in these types of beam hanger connections.

STSs offer an effective and easy-to-install option for reinforcing beam hanger connections. Reinforcement should always be detailed to avoid fastener collision, conform with prescribed spacing and end- and edge-distance requirements, and effectively distribute forces. This paper provides a number of best practices and helpful tips for designers and installers alike, such as:

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.