MTC Solutions fully threaded and partially threaded self-tapping screws (STSs) require adapted equipment for a safe, efficient, and accurate installation. This blog post provides tool recommendations, as well as detailed steps to follow for an optimized installation.

Approximately 7-minute read.

Equipment

The first key component to achieve a proper installation of the ICC-ESR-approved MTC fasteners is to have the right equipment.

The Bits

Installation of MTC fasteners require typical bits & accessories, most common of which are the patented RW bits. The new RW bits are designed for the partially threaded 4.0 series & fully threaded fasteners series, existing in three different models:

The optimized fit of the RW bits allows a deep-seated fit into the screw drive, generating a better torque transfer, easing the installation and resulting in an efficient installation, especially with large quantities of fasteners. Installation of long, 9/16 in. [ 14 mm ] diameter VG RH reinforcing fasteners (up to 59 in. [ 1,500 mm ] in length) requires the use of the high torque-transmitting reverse head socket adaptor accessory.

The Power Tools

Selecting the right drill depends on multiple factors, including the diameter and length of the fastener, the quantity being installed, and the materials involved—such as the specific gravity of the timber or the presence of steel or aluminum components.

To improve accuracy and alignment when installing long fasteners, a predrilling jig can be used to assist with angle control and positioning. Predrilling jigs also help reduce contact between the fastener threads and steel plates. We recommend using low-RPM, high-torque drills equipped with a feather (variable speed) trigger, and avoiding excessive acceleration and deceleration during the drive-in process. Fasteners should be installed in a continuous manner until seated, as stopping and restarting the drive-in process can cause increased torque peaks.

The use of impact drills is not recommended for installing STSs—especially in beam hanger applications—due to the risk of overtorquing and the cyclic fatigue loading caused by their stop-and-go impact action. This can compromise fastener integrity, particularly in long or large-diameter screws. For more information on this recommendation, see our blog post, “Why Impact Drills Might Not Be the Best Tools for Mass Timber Hardware Installation?”

Regardless of the drill used, all fasteners must be installed within the recommended torque range. Allowable insertion torques for MTC fasteners are listed below.

Preparation

Before driving the fasteners, pilot holes or predrilling may be recommended. Examples include—but are not limited to—installation in wood species with specific gravities exceeding 0.49 or in species more sensitive to splitting; installation with reduced spacing, end, and edge distances; installation of fasteners with length exceeding 16 in. [ 400 mm ]; or installation into extremely dry (< 10% MC) timber. Pilot holes and predrilling also help reduce installation torque, result in less wear on tools, and increase installation precision. To learn more, read our tips & tricks blog post on the subject.

Installation

To optimize the installation of MTC self-tapping screws, here is a list of tips & guidelines to follow:

A predrilled hole might be required prior to installation. Drill along the desired angle of the fastener following pre-drilling recommendations from our design guide. Do not force the fasteners’ position by using a hammer. It may damage them.

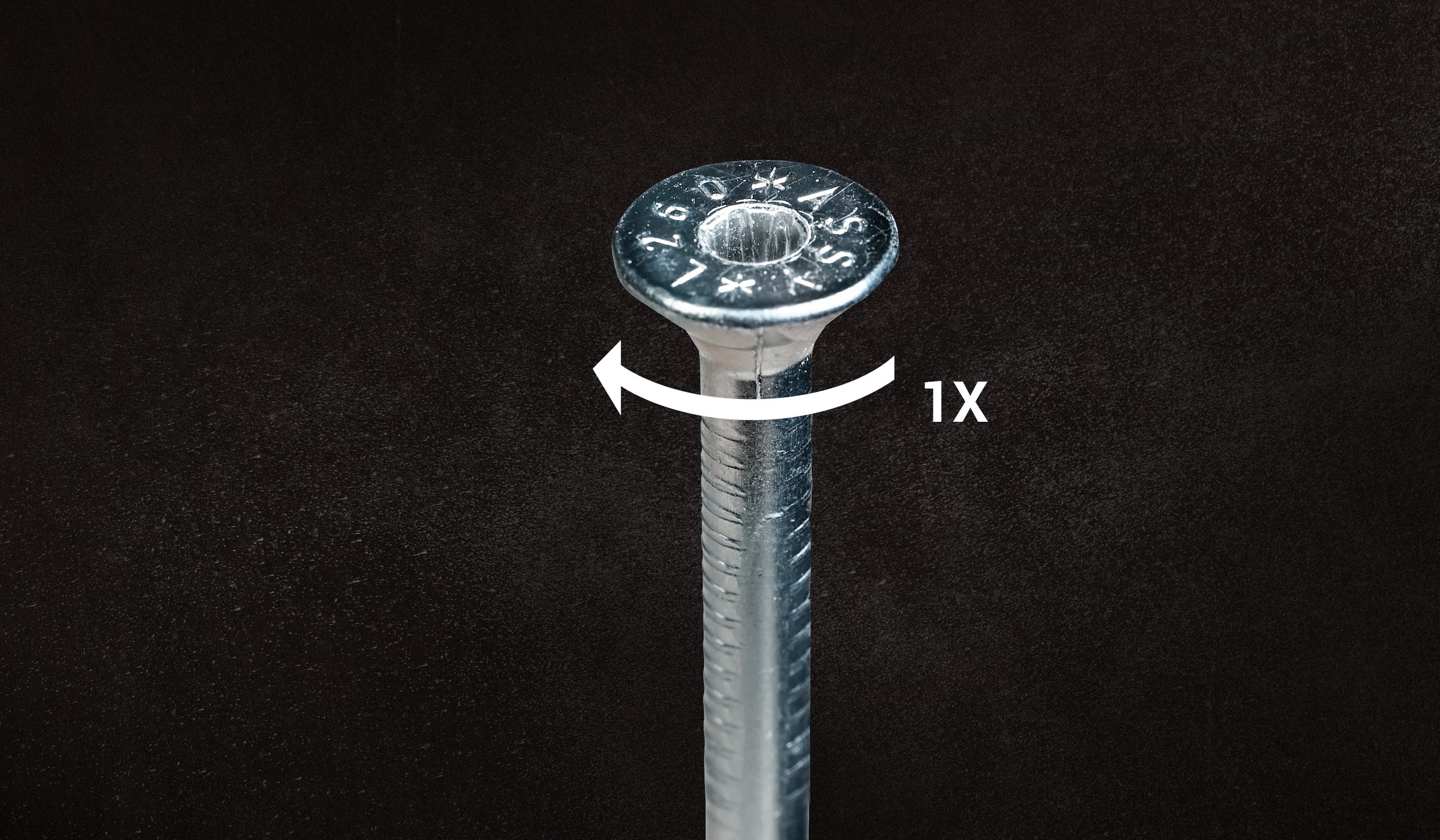

The RW drive bits and drill must be parallel to the fastener axis during installation to avoid stripping the bit or bit seat assuring proper torque transmission.

It is recommended to install MTC STSs in one continuous run. Restarting fasteners installation, especially long fully threaded ones, can be quite challenging and often yields difficulties.

Once the fastener is engaged in the wood members, do not apply an excessive downward force on it as it may buckle slender fasteners during installation and alter their direction of installation.

When completing the fastener installation, it is recommended to slow down the rotation speed of the drills once the fastener head is approximately 1/2 in. [ 12 mm ] from being seated. This will help avoid over-torquing the fastener. This is especially important in steel-to-wood connections or when using an impact drill.

If wood splitting is observed during or prior to installation, a qualified design professional must be contacted. Observed irregularities such as fastener damage or breakage must always be reported to a qualified design professional.

For more information on design properties of MTC Solutions fasteners, download our Structural Screw Catalog. Download our Structural Screw Connection Design Guide for engineering design values and specifications.

If you have any questions, contact our Technical Support Team 😉.

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.