Corrosion can weaken fasteners in mass timber connections over time, but with the right choices, you can protect your build. In this article, we’ll share expert tips to prevent corrosion and ensure lasting, reliable structures.

Approximately 3-minute read.

To effectively combat corrosion, it’s crucial to first evaluate the conditions your fasteners will face and then choose the right materials and methods to protect them.

I. Corrosion Risk Evaluation

Consider factors like the potential for exposure to moisture, salt (e.g., think pedestrian bridges), and pollutants (e.g., fertilizers, chlorides, and sulfates).

Check the acidity (pH) of the wood species—some woods, like yellow, red, and Alaskan cedars, are more acidic and may increase corrosion risks.

II. Material Selection & Compatibility

Choose the right fastener for its intended function and corrosion resistance.

Use stainless steel for pressure-treated timber, taking advantage of its superior corrosion resistance without a damage-prone coating.

For wet service conditions, prevent galvanic corrosion by avoiding contact between electrochemically dissimilar metals (e.g., galvanized fasteners and stainless steel plates). Opt for materials with similar electrochemical properties or, when necessary, isolate dissimilar metals with plastic washers.

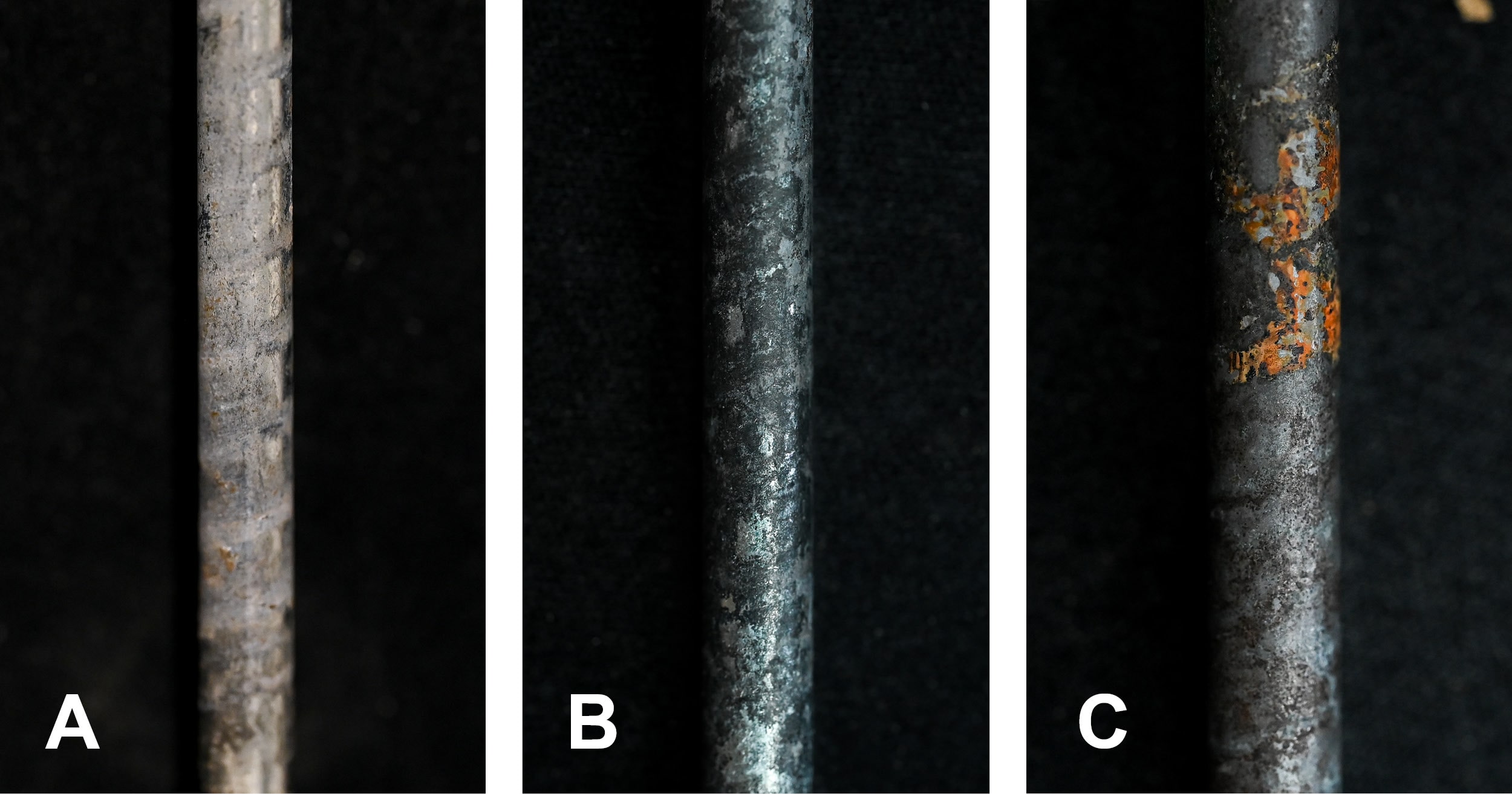

Zinc-plated fasteners may develop white and black rust, which is typically cosmetic. However, red rust, which generally forms when the zinc coating is compromised, indicates steel corrosion, signaling inappropriate fastener selection and potential connection failure. In such cases, it’s imperative to replace fasteners with appropriately designed corrosion-resistant alternatives.

Figure 1. Images of (A) white rust, (B) black rust, and (C) red rust formed on mass timber screws tested in-house for corrosion performance in SPF and D. Fir specimens in late 2024

III. Moisture Considerations

Accommodate wood swelling and shrinkage due to fluctuating moisture conditions to prevent excessive perpendicular-to-grain tension in wood. For example, use multiple narrow steel side plates rather than one wide plate.

Detail connections to promote shedding of water and prevent pooling.

Account for strength reductions by applying the appropriate wet service factor.

Plan for green wood use through appropriate detailing that accommodates high-moisture timber.

IV. Protecting Metals

Avoid damage to surface coatings on metal components to maintain protection against corrosion.

Corrosion doesn’t have to be a threat to your mass timber connections. By evaluating service conditions, selecting the right fasteners (more details can be found in our Structural Screw Catalog and blog post, The Right Fastener for the Job: Navigating Service Environments in Mass Timber), and accounting for moisture and material compatibility, you can build durable, long-lasting structures.

Have questions about the best fastener choice for your project? Our Technical Support Team is here to help! 😉

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.