When it comes to mass timber hardware installation, using the right tool makes all the difference. While impact drills might seem like a convenient option for installing structural fasteners, they can actually end up causing more harm than good.

In this article, we’ll explain why that’s the case and share why MTC Solutions generally advises against using them for structural hardware installation (unless specific precautions are taken).

Approximately 6-minute read.

What Impact Drills Are Good for

Before we get into why we generally don’t recommend the use of impact drills, we acknowledge that they are a popular choice on construction sites for a variety of reasons:

These powerful tools shine in various construction tasks, particularly those involving hardware and devices that are less sensitive to overtorquing and fatigue, such as nuts and bolts, heavy equipment, and structural steel assemblies and connections. Their high torque output makes them ideal for challenging materials, and by minimizing kickback, they help reduce strain on the operator. When used in the right applications, impact guns can significantly boost productivity on a job site.

However, when it comes to structural fasteners in mass timber, the game changes completely.

Choosing the Right Tool: Rotary, Impact, or Percussion?

With so many drill types on site, it’s important to pick the one best suited to mass timber fastener installation.

Understanding these differences ensures you’re using the safest and most efficient tool for your installation.

Rotary Drill vs. Impact Drill, Which One is Faster?

Before we delve into “why” impact drills are likely not the right tool to install mass timber hardware, the MTC Solutions team took on a quick hands-on experiment. Following up on the industry hot topic about impact drills, we tested the installation speed of 3/8 in. × 8 in. [ 10 mm × 200 mm ] fully threaded fasteners into a beam hanger system, comparing a 20V cordless rotary drill vs. an 18V high-torque impact drill….and the results were eye-opening! See for yourself 😉

Impact Drills Don’t Cut it for Structural Fasteners

Despite all their strengths, impact drills are simply not suitable for installing structural fasteners in mass timber projects. Here’s why:

Mass timber screws, with their hardened casing, are more vulnerable to damage from excessive torque and fatigue. Impact drills, with their signature stop-and-go motion, can actually cause cyclic fatigue loading, potentially weakening the fastener. This is especially true in long screws (over 8 in. [ 200 mm ]) and in higher-density timber (e.g., southern yellow pine), for which higher torque is required.

Rotary drills with a feather trigger, on the other hand, allow for precise control and consistent torque, crucial for mass timber screws. For more details, refer to the ICC Evaluation Service Report 3178.

Figure 1. Idealized torque output comparison between impact drills and rotary drills

Made from high-strength steel, structural screws are designed to be slender for optimized installation into wood. However, this profile also requires an installation torque significantly lower than the typical output of impact drills. Using an impact drill can easily exceed this limit, leading to accidental over-stressing (i.e., overtorquing, see annex at the end of this blog) and potential fastener damage.

The lack of feedback from impact guns, while handy in some applications, becomes a problem here. It’s harder for installers to detect if something goes wrong during installation—until it’s too late.

In short, impact drills can compromise the structural integrity of fasteners, reducing their strength and impairing their ability to transmit structural loads and demands. This weakening increases the risk of fastener breakage. What’s more, the damage is often invisible, making it difficult to detect and heightening the chance of unexpected failure in design load scenarios.

If you want to know How to Install Structural Self-Tapping Screws in mass timber applications, then this article is the right one for you, otherwise, our Technical Support Team is just a message away if you have any questions or need further assistance 😉

Annex

The following annex section of the blog article covers the primary factors that influence fasteners’ insertion torque. This is complementary information to the overtorquing risks associated with the use of impact drills when installing structural hardware.

Key Determinants of Insertion Torque

Generally, the denser the wood, the more torque you’ll need to drive a screw in, assuming the moisture content (MC) remains constant. Higher specific gravity means that the wood fibers are tightly packed together, increasing the resistance and therefore the rotational force required.

Driving screws perpendicular to the grain requires the highest torque. As the angle of installation decreases from 90° to 0° relative to the grain, a progressive reduction in required torque is observed, with the lowest torque needed when driving screws parallel to the grain.

Wood with higher MC tends to be softer and more pliable, and has been shown to reduce the torque needed and make it easier to drive the screw in.

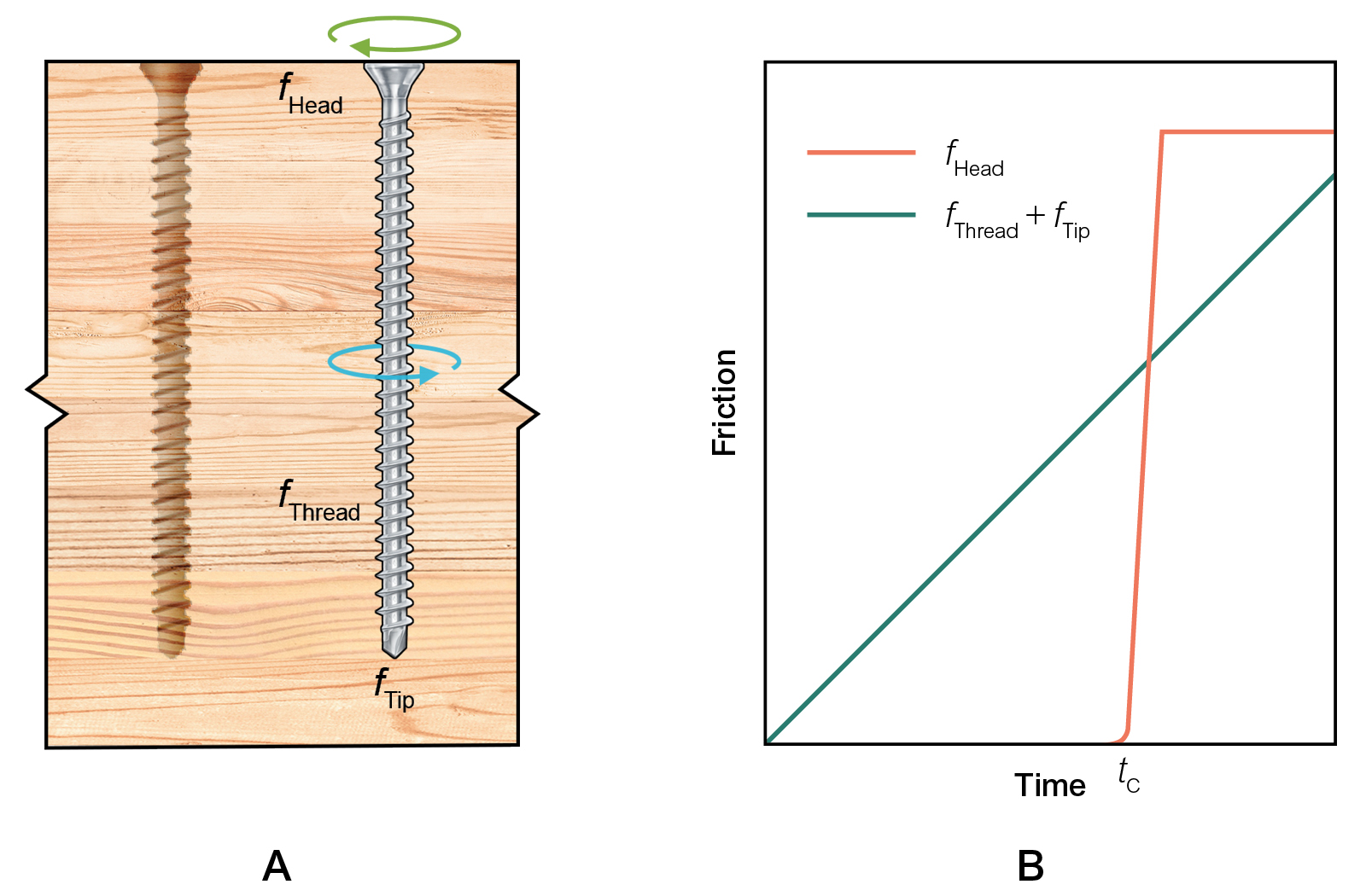

Drive-in friction—a major factor in required torque—arises from several elements. As the screw’s self-tapping tip “mills” and displaces wood fibers during installation, it generates resistance, much like a drill bit. However, the primary contributor to torque is the physical friction between the screw’s cylindrical body and the wood fibers. The screw’s diameter plays a critical role here—larger diameters increase friction. Additionally, the screw wings contribute further resistance, adding to the overall torque demand.

Seating the screw head onto the wood member or the steel plate requires extra torque, as the friction increases when the threads pull the head into place.

Figure 2. (A) A screw being driven into wood experiences friction from two primary sources: (1) the displacement of wood by the tip and the rubbing action between the screw threads and the wood (fTip + fThread), and (2) the friction between the head and the wood once contact is established (fHead). These forces together determine the overall insertion torque. (B) As installation progresses, fTip + fThread gradually increases, while fHead emerges only when the screw head contacts the wood (tC), rising sharply thereafter. (illustrative plot)

While all of these factors impact insertion torque, specific gravity, grain orientation, and drive-in friction are the most important to watch out for in wood-to-wood connections. In steel-to-wood connections, head seating friction (torque) is also critical, as it can lead to the screw head snapping off or pose a safety risk to the operator.

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.