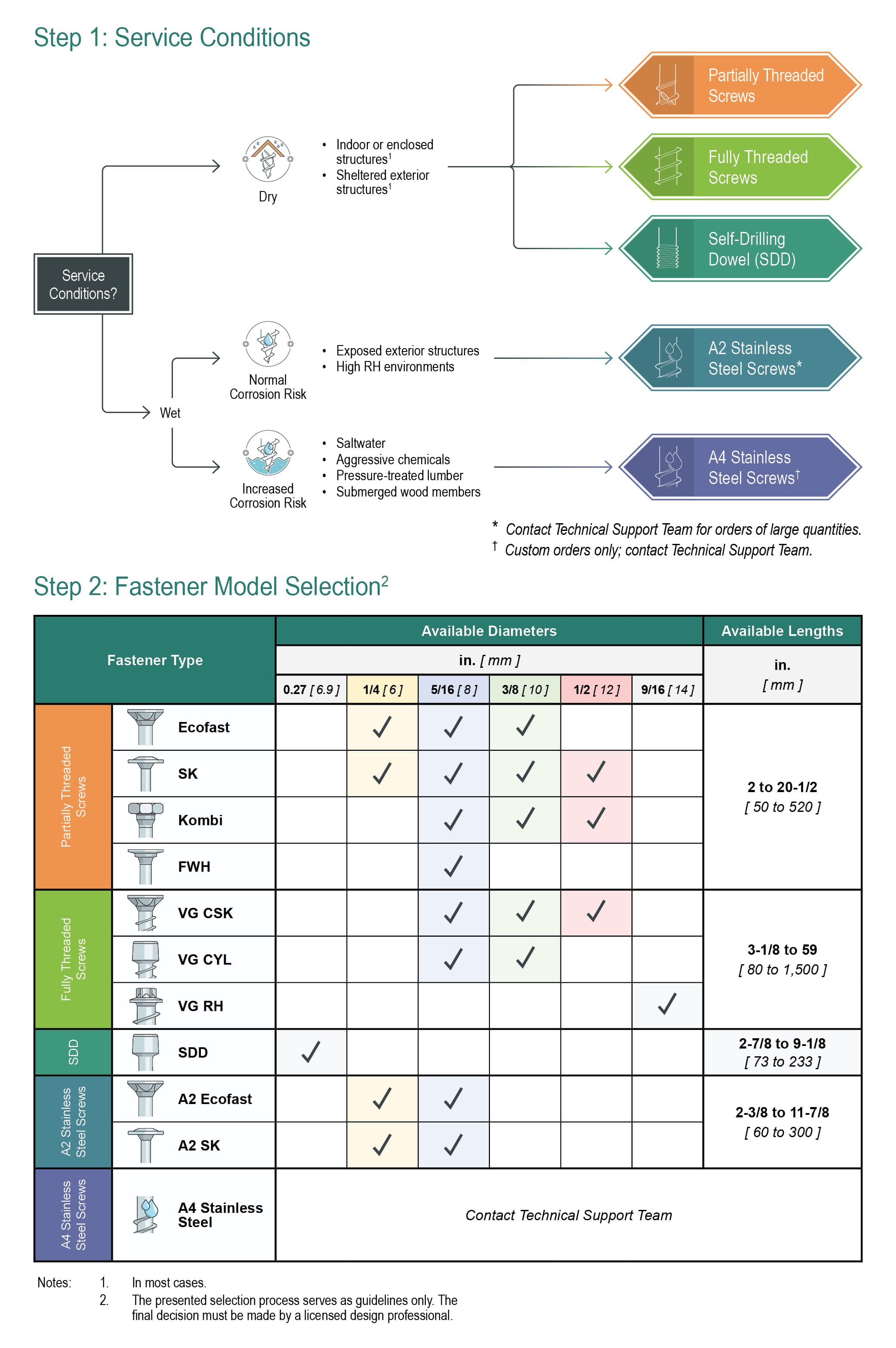

When selecting fasteners for mass timber projects, understanding service conditions conducive to corrosion—such as wood with high moisture content—is crucial. These factors directly impact fastener durability, making them a top priority for designers to consider.

In this article, we’ll explore dry and wet service environments and recommend suitable fasteners for each to ensure your connections stay strong and durable.

Approximately 6-minute read.

The first step in designing mass timber connections is understanding the environment your structure will face. Will the connection remain indoors in a dry, conditioned space, or will it be directly exposed to water or high levels of humidity for prolonged periods?

In short, assessing the anticipated moisture content (MC) of the wood in service is essential. It determines whether carbon steel or stainless steel is the right material for your fasteners, as each offers varying levels of corrosion resistance.

Dry Service Conditions

In both the U.S. and Canada, a dry service environment for wood connections means the timber’s MC is not expected to exceed 19% at any time throughout its service life. Canada goes a step further by requiring climatic conditions (i.e., temperature and relative humidity (RH)) that ensure the average equilibrium MC will remain below 15% on average over a year.

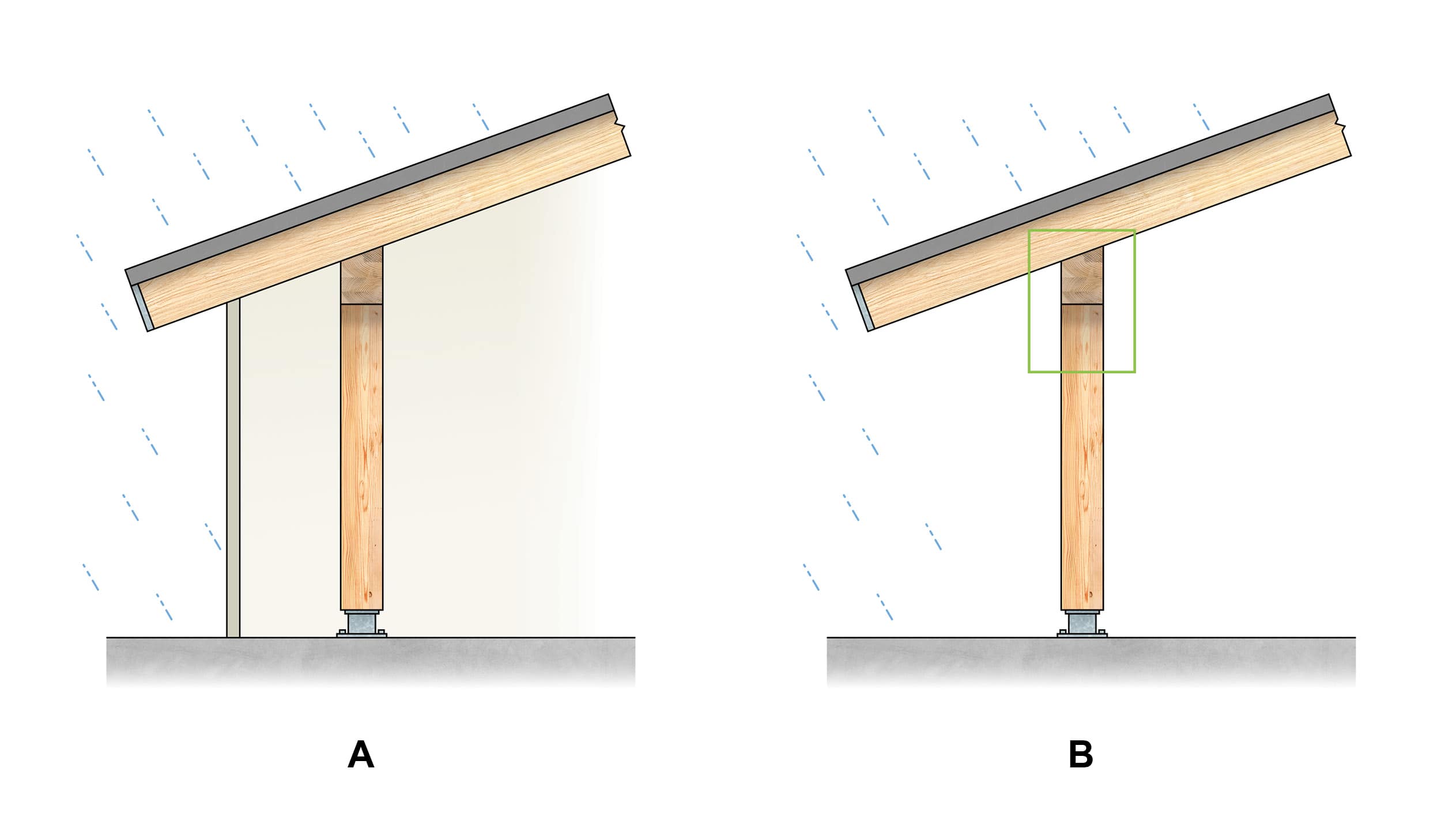

Typical dry service environments include:

Figure 1. Common dry service environments

For dry service conditions, MTC Solutions provides carbon steel fasteners with regular corrosion resistance:

💡Pro tip: Ensure timber’s MC doesn’t exceed 19% during fabrication (unless stated otherwise in the construction document) to prevent connection strength loss due to wood shrinking or swelling.

Wet Service Conditions

If a wood connection is expected to experience an MC greater than 19% during its service life, it falls into the “wet” service category. This significantly increases the risk of corrosion, impacting fastener durability and longevity.

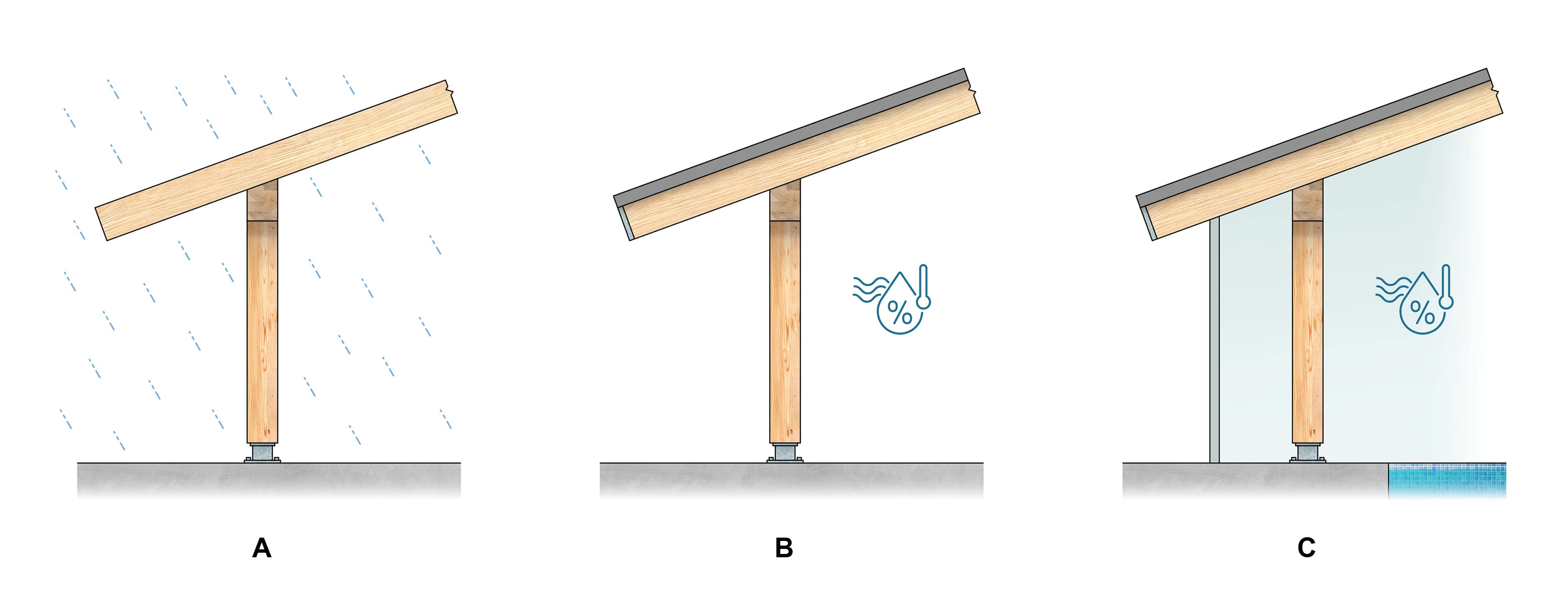

Common wet service conditions include:

Figure 2. Common wet service environments

For wet service conditions, we recommend fasteners with enhanced corrosion resistance, such as:

⚠️Why electroplated carbon steel screws shouldn’t be used in wet service conditions:

⚠️Why hot-dip galvanizing (HDG) isn’t used for corrosion protection in STSs:

Figure 3. Service conditions and fastener options at a glance

For tips on protecting your connections from corrosion, check out our other article, Tips for Preventing Fastener Corrosion in Mass Timber Connections.

💡Note: Manufacturing complexities can affect the cost and availability of carbon and stainless steel fasteners in different diameters and lengths. For more details, contact our Technical Support Team and read our article on preventing fastener corrosion.

Choosing the right fasteners means accounting for service conditions and corrosion risks. By following best practices, you can ensure durable, high-performance mass timber connections. Contact our Technical Support Team for fastener recommendations tailored to your project’s environment—or for any other questions you might have! 😉

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.