Structural self-tapping screws (STSs) are essential hardware in the making of mass timber structures. Their performance is the result of a carefully controlled manufacturing process that enhances their strength properties. Of the two common steel types used in STS production, carbon steel dominants the market with a wider selection of diameters and lengths. While stainless steel offers superior corrosion resistance, its application in STSs remains limited due to its mechanical properties coupled with production and material costs.

In this article, we’ll break down the STS manufacturing process and explore some challenges encountered while producing certain screw types.

Approximately 6-minute read.

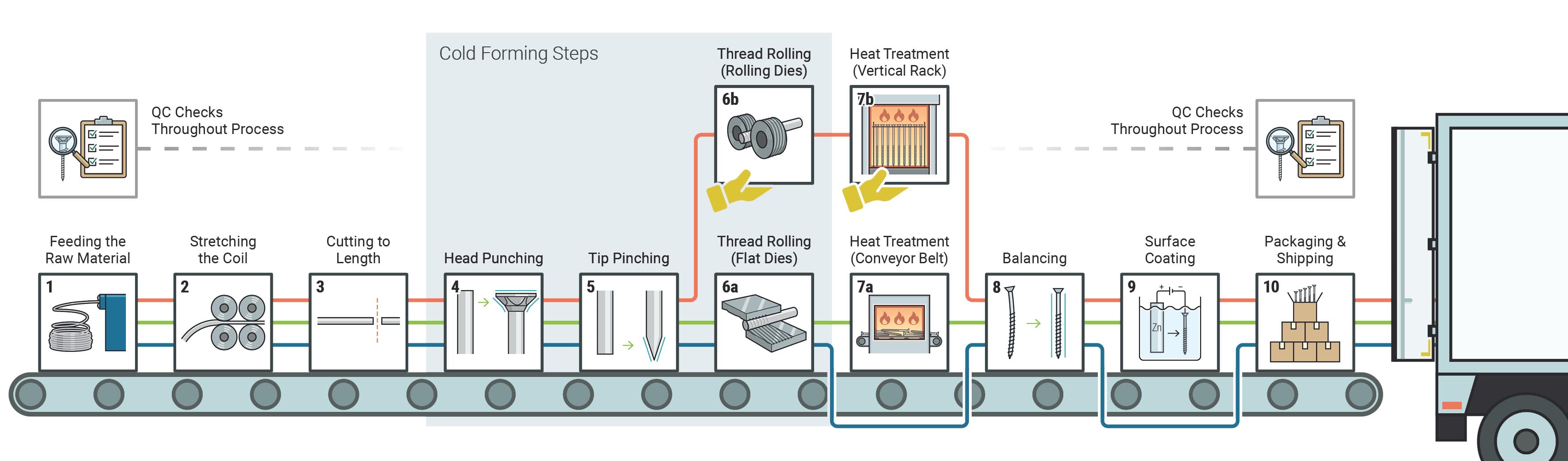

Self-tapping screw (STS) production is largely automated, though some steps require manual operations. Stringent quality control (QC) procedures are implemented throughout the process to ensure compliance with industry standards. The scrolling flowchart below shows the major steps involved in this process:

*QC checks: Conducted throughout the process.

💡 How does screw length affect production costs?

Longer screws cost more to manufacture due to greater material use and increased manual labor required in two steps of the process: thread rolling and thermal treatment:

Flat dies are fully automated and faster but limited to shorter screws.

Horizontal rolling dies—consisting of grooved spinning wheels—are, however, required for longer screws. This method involves manual handling, increasing production costs.

A conveyor belt automatically feeds shorter screws into the heating chamber.

Longer screws, however, must be manually placed vertically in a cage before entering the chamber, adding to production costs.

Importantly, screw manufacturing costs do not increase linearly with length.

💡 Does screw diameter affect cost?

Yes, mainly due to higher material costs.

💡 Carbon steel vs. stainless steel in strength and manufacturing

Stainless steel does not go through thermal treatment. Stainless steel screws share the same tensile strength of ~600 N/mm2 with the raw material.

In comparison, carbon steel is thermally hardened during the process. Heating results in a considerably higher tensile strength of 900–1,200 N/mm2 for carbon steel screws, compared to both that (400–500 N/mm2) of raw carbon steel and that of stainless-steel screws.

The thermal treatment for carbon steel screws creates a “soft” core and a hardened case, allowing them to withstand both the drive-in torque during installation and heavy loads by yielding and deforming without breaking in service. This makes carbon steel screws the preferred choice for mass timber applications in dry service conditions, where both installation performance and long-term load capacity are key considerations.

💡 Why are stainless steel screws more expensive?

Beyond their application possibilities, stainless steel screws are considerably more expensive to manufacture compared to carbon steel screws due to two key factors:

💡 Limitations of stainless-steel screws

Stainless steel screws are a viable choice for applications requiring corrosion resistance due to their durability, notably in wet service conditions, provided that the forces from wood movement stay within their tensile capacity. If you’re designing for such service conditions and want to learn more, check out the following article that outlines key considerations:

Manufacturing STSs is a complex process that balances strength, cost, and performance. If you have questions about selecting the right fasteners for your project, our Technical Support Team is here to help! Reach out today to get expert advice on the best solutions for your mass timber applications. 😉

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.