MTC Solutions offers an extensive range of ASSY® self-tapping screws, available in a variety of sizes and head shapes for both partially and fully threaded options. This article compares the characteristics, design features, and functions of the partially and fully threaded screws. Key considerations are also presented to assist designers in selecting the most suitable screws for their specific applications.

Approximately 7-minute read.

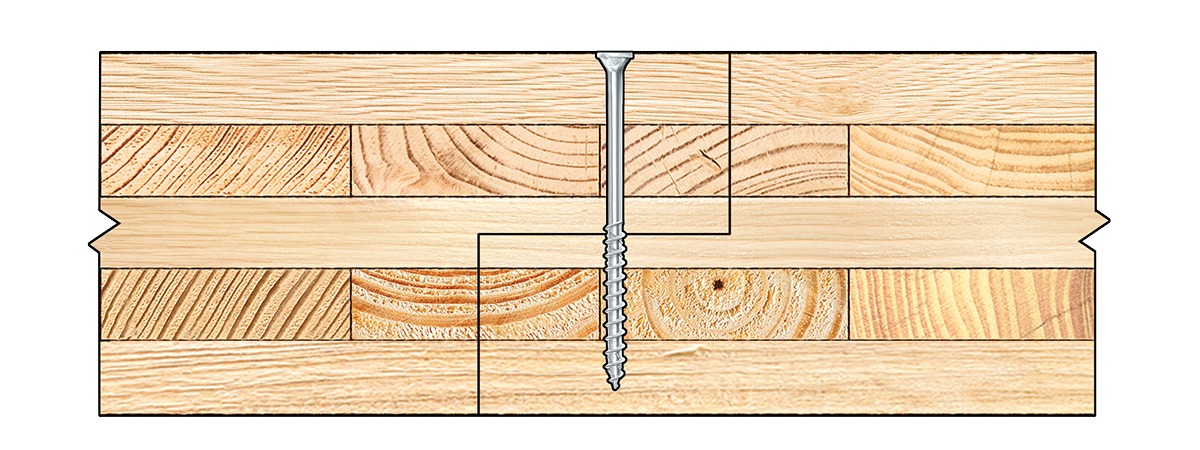

Modern self-tapping screws (STSs) generally fall into two categories: partially and fully threaded. A partially threaded screw contains a shank consisting of both a threaded portion and a smooth portion, with the latter positioned between the threaded portion and the head. This design allows the side member to move freely along the unthreaded portion. In contrast, a fully threaded screw features threads along its entire shank, restricting the movement of the side member or the main member along its axis. Both types are equipped with a self-tapping design, eliminating the need for pilot holes or predrilling to facilitate their installation.

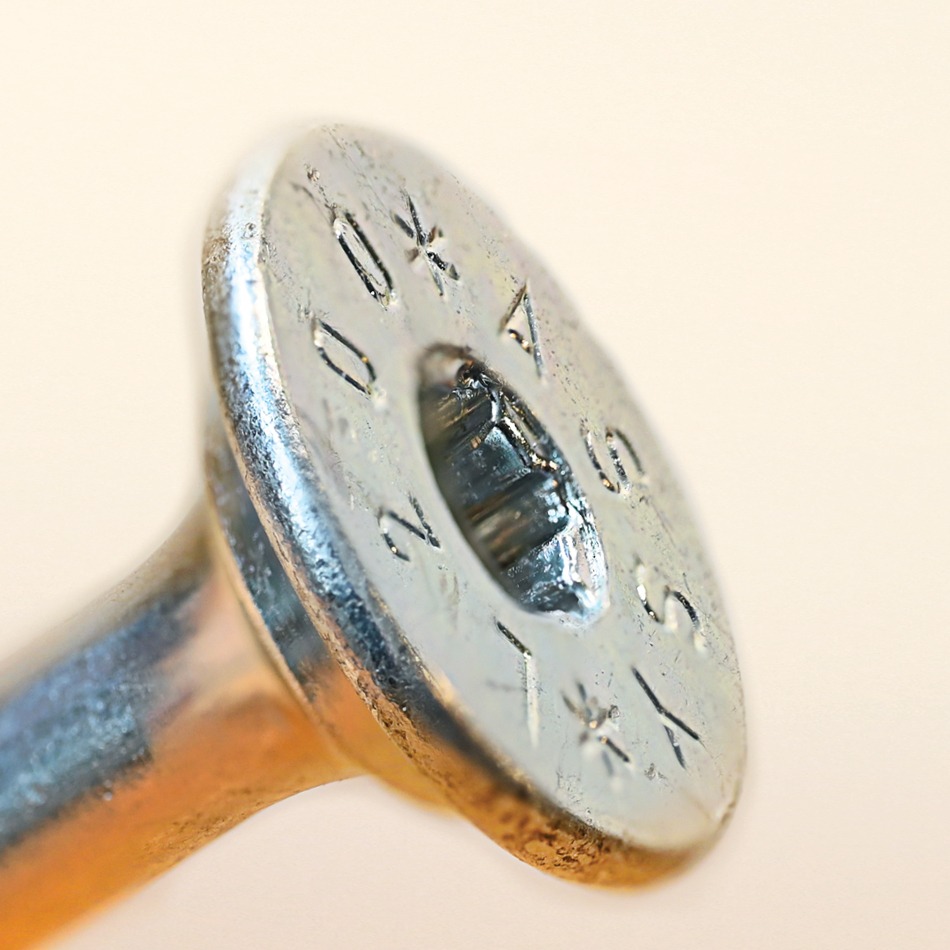

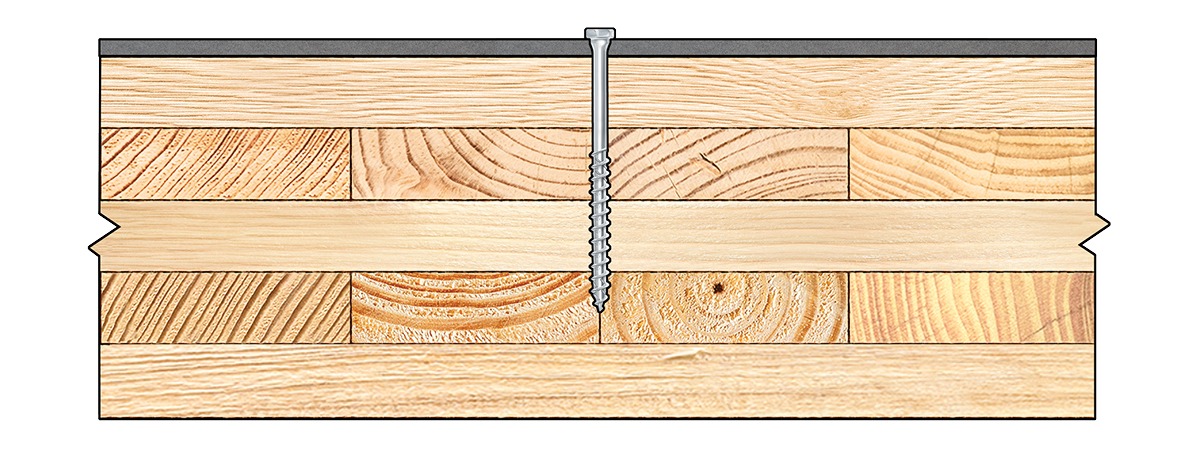

All STSs undergo a case-hardening process that imparts them with a ductile core and a high-density layer towards the outer diameter. This treatment yields an optimal bending yield strength along with exceptional ductility and stiffness, which prove advantageous for shear and withdrawal applications, respectively. Electroplated with a zinc coating, ASSY® carbon-steel partially and fully threaded fasteners (see Figure 1 for their structural differences) are adequate for use in dry service conditions.

Figure 1. Structural comparison of partially and fully threaded screws

Partially Threaded Fasteners

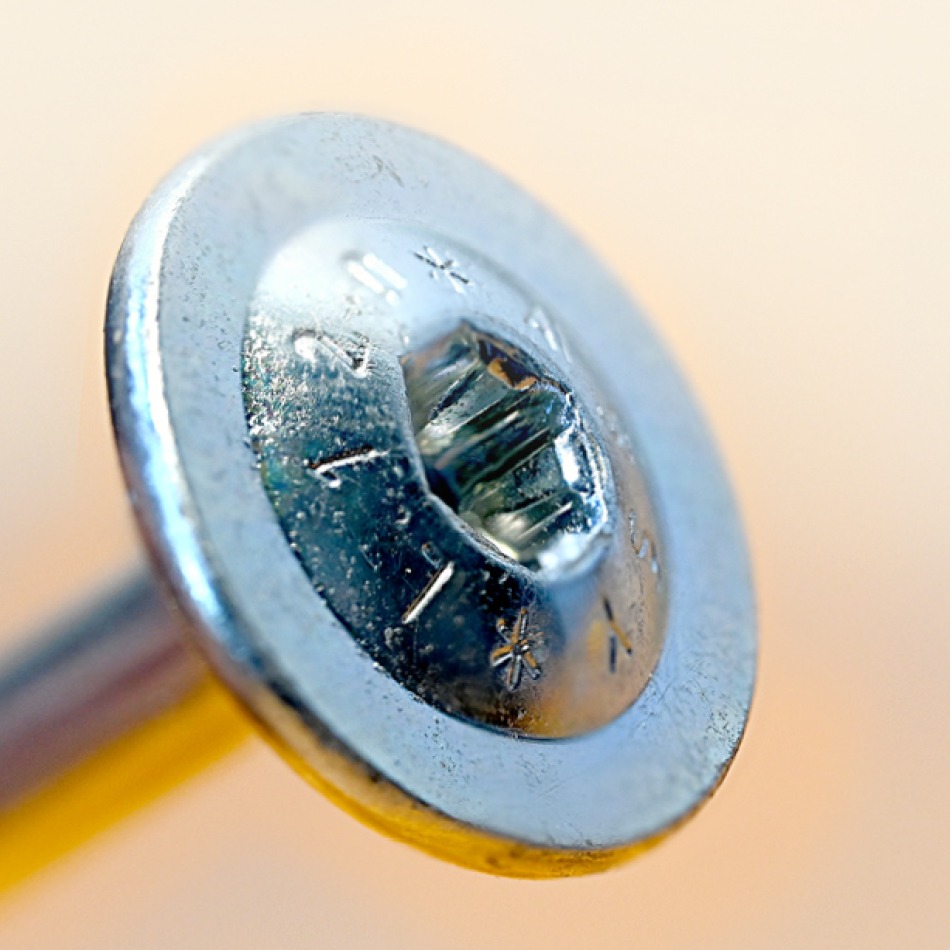

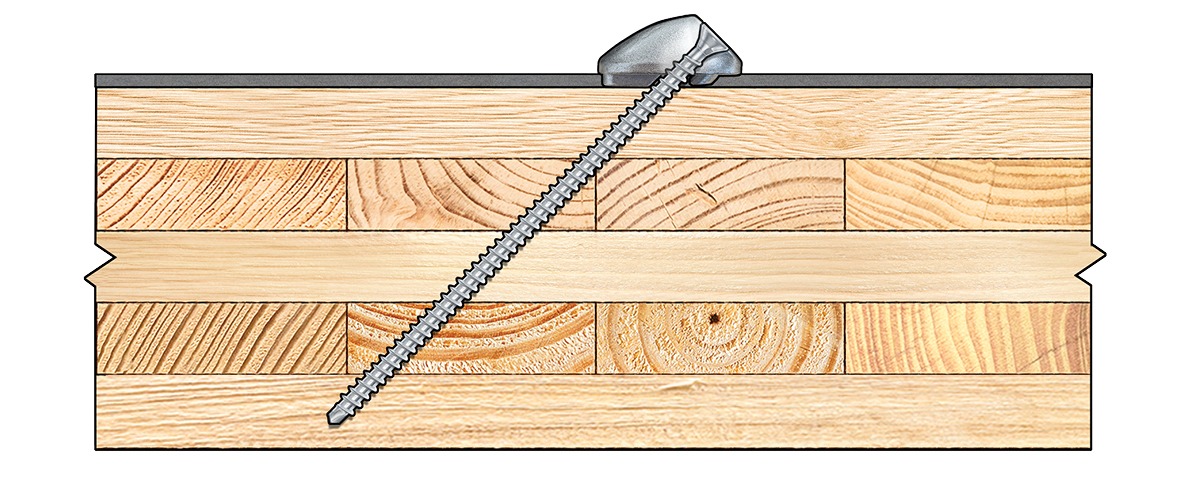

Partially threaded fasteners exhibit distinctive design features in their tip, shank cutter, and head. Each of these screws is equipped with a reamer tip capable of quickly biting into wood, facilitating rapid installation while minimizing the risk of wood splitting. Embedded within the thread, the shank cutter reduces the friction created by the passage of the shank by widening the installation hole, thereby decreasing the torque required for installation. Each screw head is designed specifically to provide unique properties to the overall connection. Below is a summary of the characteristics and benefits of the various head shapes of these partially threaded fasteners.

Countersunk Head, Featured in Ecofast Screws

The countersunk head, known for its high versatility, enables a clean architectural finish suitable for both wood-to-wood and steel-to-wood connections. To enhance efficiency in steel-to-wood connections, screws furnished with this head shape, known as Ecofast, can be installed together with MTC Solutions’ 90° Cup Washer.

Washer Head, Featured in SK Screws

Large in size, the washer head is designed to deliver an exceptional head pull-through capacity. Screws featuring this head shape, referred to as SK, are an ideal choice for wood-to-wood connections and may also be used for steel-to-wood connections.

Hexagonal Head, Featured in Kombi Screws

Kombi screws are equipped with a hexagonal head with a widened under-head shoulder engineered for use in high-performance, slip-free steel-to-wood connections. They can be installed with either an RW bit or a Magnetic Socket.

Flat Washer Head, Featured in FWH Screws

The flat washer head combines the high head pull-through capacity of a washer head with a flat design that enables embedment into the wood surface to deliver a flush architectural finish. Screws with this head shape, known as FWH, are particularly well-suited for wood-to-wood connections.

Examples are provided in Figure 2 to demonstrate the use of partially threaded fasteners in different connection configurations, as determined by their head shape.

(a) Knee brace connection (a type of post-to-column connection) facilitated by SK fasteners

(b) Half lap joint (a type of panel-to-panel connection) facilitated by Ecofast fasteners

(c) Steel plate-to-panel connection facilitated by Kombi fasteners

Figure 2. Applications of partially threaded fasteners equipped with various head shapes

Fully Threaded Fasteners

Fully threaded screws feature a specialized tip that mimics a drill bit, effectively reducing the splitting potential of the wood. This characteristic proves valuable in accommodating tighter geometry requirements, especially in scenarios warranting numerous fasteners to withstand high load demands. Threaded along their entire shank, these fasteners offer high withdrawal resistances, making them an ideal option for axial loading applications. Like partially threaded fasteners, fully threaded fasteners come in various head shapes, each providing distinct advantages that are discussed as follows:

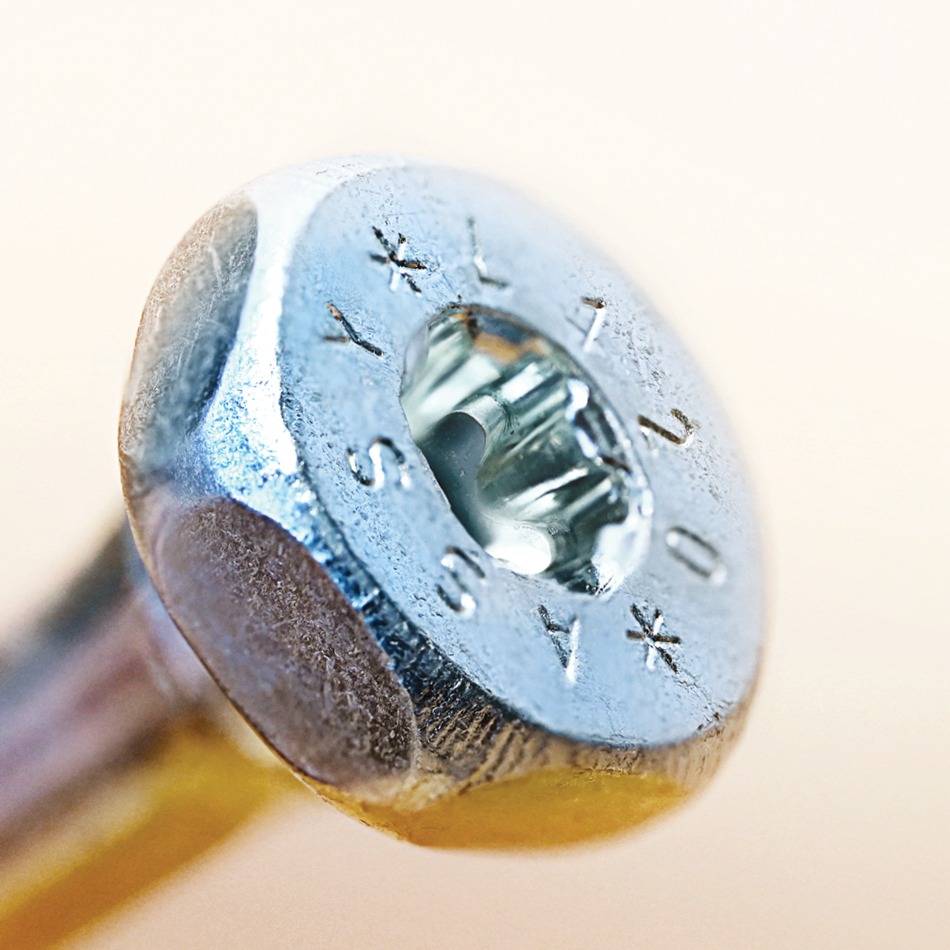

Countersunk Head, Featured in VG CSK Screws

Similar to their partially threaded counterparts, screws with a countersunk head, referred to as VG CSK, are a perfect choice for steel-to-wood connections under lateral loading. These screws can be installed at an incline with 45° Wedge Washers. VG CSK screws are used to install MTC Solutions’ beam hangers.

Cylinder Head, Featured in VG CYL Screws

The cylinder head is designed to be small enough to be almost invisible when installed, as it will drive itself into the wood member. Such feature makes screws with this head design, known as VG CYL, the preferred choice for reinforcing both new and in-situ timber beams.

Reverse Head, Featured in VG RH Screws

VG RH Screws, currently the longest screws offered by MTC Solutions, feature a specially engineered reverse head, designed to use a 6-point Reverse Head Socket to achieve maximum torque transfer while minimizing the risk of head stripping. With lengths up to 59” [1.5 m], these screws are perfectly suited for massive-scale reinforcement.

Figure 3 provides examples of the use of fully threaded fasteners in different connection configurations, as determined by their head shape.

(a) Steel plate-to-panel connection facilitated by VG CSK fasteners and 45° Wedge Washers

(b) Cross-laminated timber panel reinforcement with VG CYL fasteners

Figure 3. Applications of fully threaded fasteners equipped with various head shapes

How to Select the Right Screws?

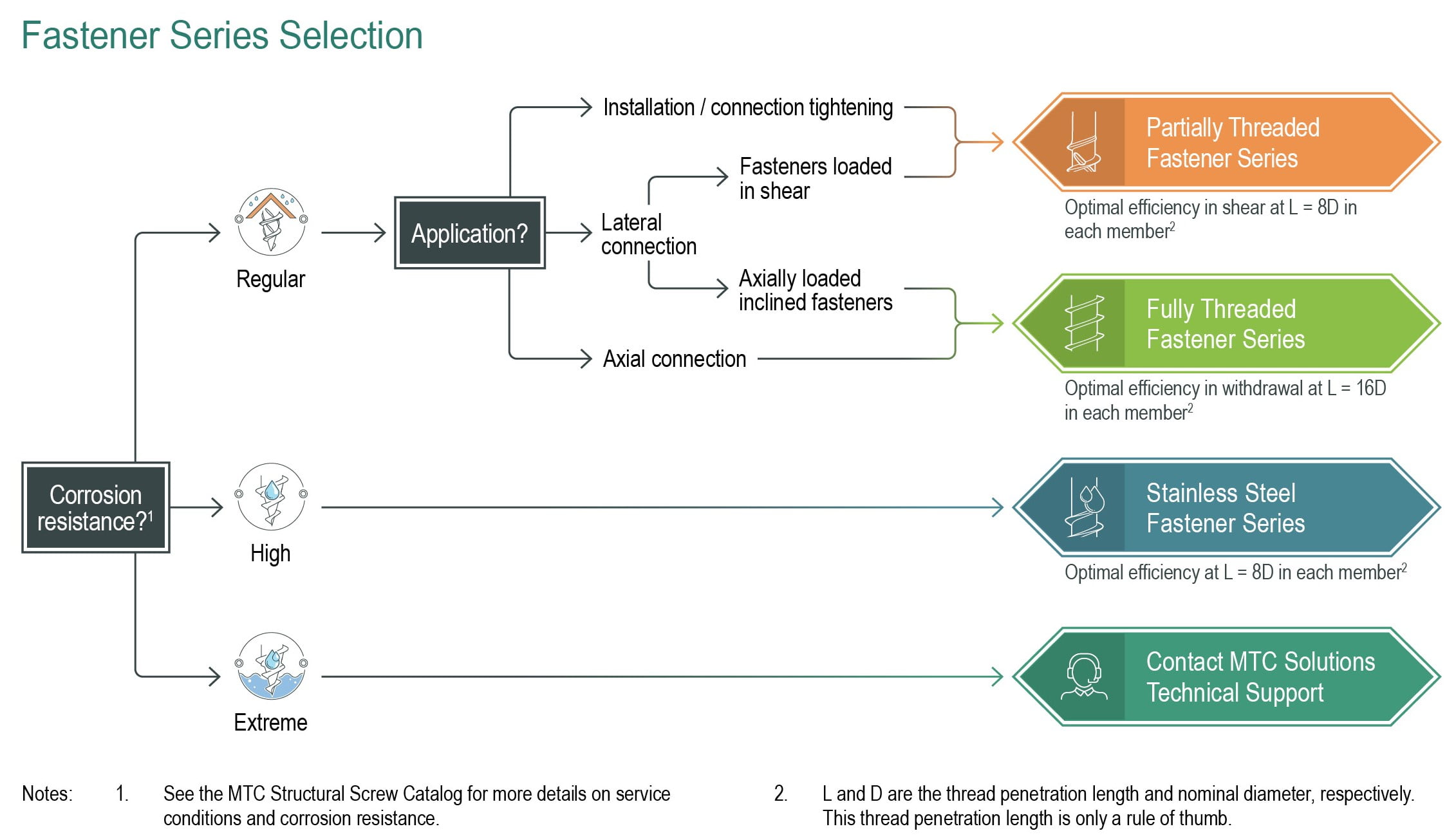

Several factors merit consideration in the selection of the right screws.

(1) Service environment. As mentioned earlier, the carbon-steel fasteners MTC Solutions supplies meet most of the current market demands and are adequate for use in dry service conditions. Additionally, MTC Solutions offers a selection of partially threaded screws in chromium-nickel austenitic A2 stainless steel, making them suitable for use in low-level and specific corrosive environments, as well as in wet service conditions. Read our blog post on Dry & Wet Service Conditions for more information.

(2) Head shape. Selecting the appropriate head shape entails careful consideration of three main factors: the composition of the connection materials (e.g., wood, steel, and/or concrete), the demand for load-bearing capacity, and the desired architectural aesthetics, the last of which often governs the choice of solutions.

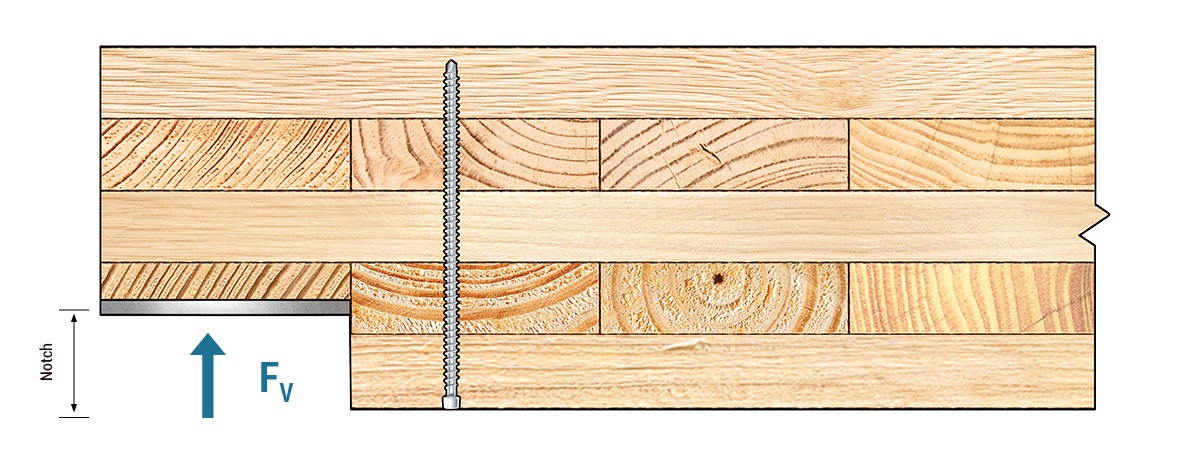

(3) Anticipated loading conditions. With superior pull-out capacity derived from high thread engagement, fully threaded screws are recommended for connections subjected to withdrawal loading. Conversely, partially threaded screws are an excellent choice for shear connections, as the unthreaded section of their shank allows the side member to slide, effectively bringing it closer to the main member.

(4) Length. Wherever possible, opting for shorter fasteners offers a cost-effective solution. Designers should always aim for the shortest fastener that meets their connection needs, as this minimizes material usage and thus reduces cost. Additionally, longer screws do not necessarily translate into increased capacity beyond a certain point, where the failure mode is influenced more by the material properties of the fastener than wood failure. As a rule of thumb, optimal efficiency is generally achieved when the thread penetration length (L) in each member reaches eight times the fastener’s nominal diameter (D) for shear connections and 16D for withdrawal connections.

The chart below facilitates quick navigation of available options and offers tips to aid selection. Individual project requirements may dictate alternative fasteners. It is advisable to consult with a licensed design professional to ensure the selection of the correct fasteners for the specific application. For more information, please refer to Pages 22–24 of our Structural Screw Catalog.

For more information on the capacity and installation requirements of partially and fully threaded STSs, please refer to our Structural Screw Catalog. If you have any questions, please contact our Technical Support Team. 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.