As mass timber construction gains momentum in North America, designers frequently turn to European design standards for structural hardware like ASSY self-tapping screws (STSs), which are often regarded as more established, given their earlier development. However, directly applying European design values in North American projects can lead to significant design errors due to regional differences in design standards. For safety and optimal performance, it’s crucial to apply these values accurately according to each jurisdiction’s code requirements.

In this article, we’ll unpack the distinctions between North American and European approaches to design values for STSs and show how MTC Solutions simplifies the design process for Canadian and U.S. mass timber projects.

Approximately 6-minute read.

European vs. North American Design Values

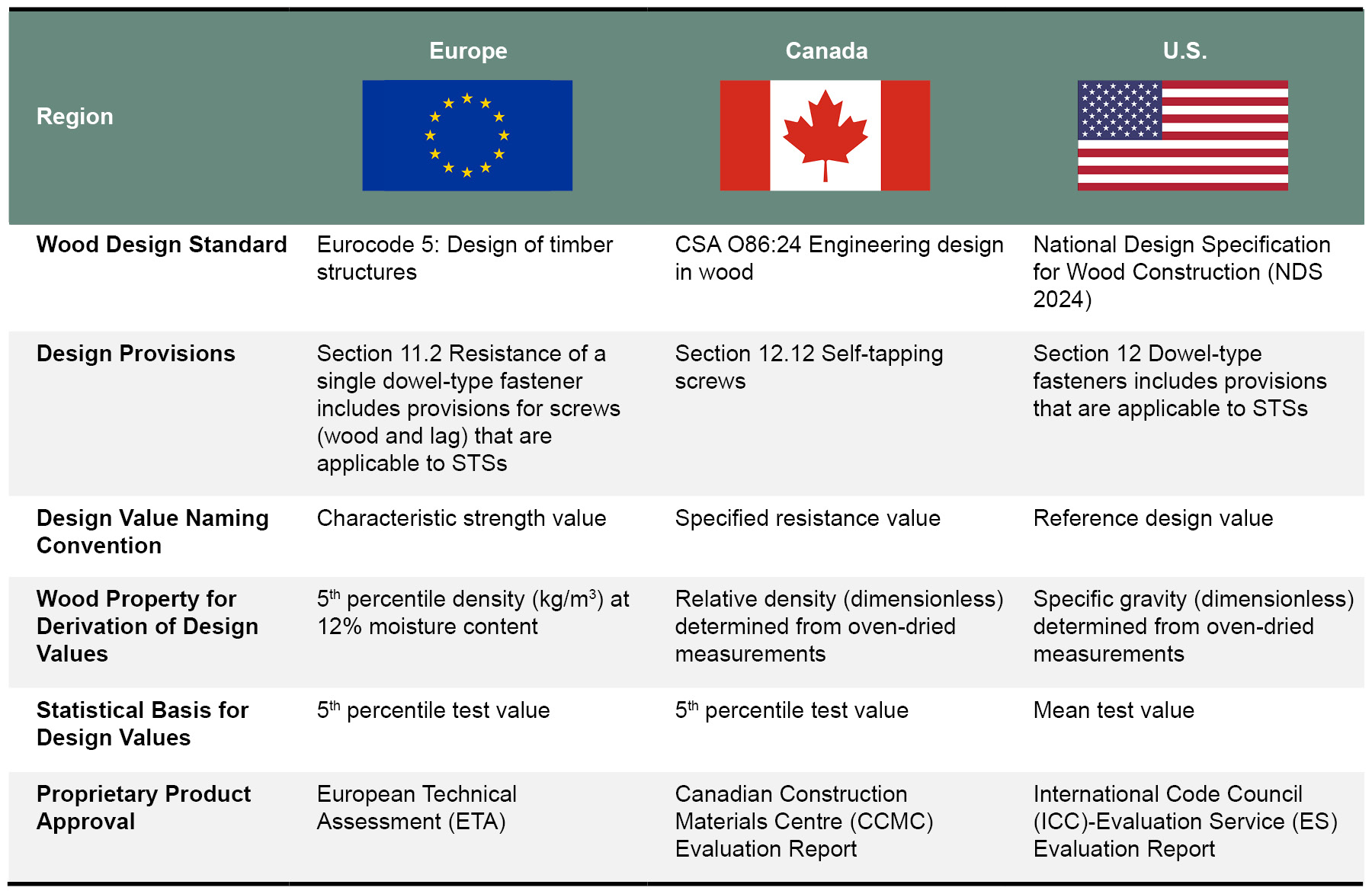

The table below summarizes the certification frameworks and wood design standards for Europe, Canada, and the U.S. They are foundational for establishing design values—like withdrawal, head pull-through, and lateral resistance—for STSs in mass timber connections.

Each region’s design values are based on unique combinations of wood properties and statistical methods. This means that transferring values directly from one framework to another can lead to substantial design errors in many cases.

Currently, many European hardware suppliers provide two types of design values for the North American market:

Using these Eurocode-based values without adjustments to align with North American design standards can overestimate connection capacity by as much as 100%.

These values should only be used with a clear understanding of how they’re derived from testing and applied in design equations.

Canadian vs. U.S. Design Values

Despite their similarities, Canadian and U.S. design values are not directly interchangeable.

CSA O86:24 (Section 12.12 for self-tapping screws) provides equations for calculating factored resistance values for STSs using specified resistance values, which can be obtained in one of two ways: (1) identifying the 5th percentile test value with a 75% confidence interval through testing per Chapter 17 guidelines; or (2) by referencing a published test report from CCMC or ICC-ES.

NDS 2024 provides equations for calculating adjusted design values using reference design values, which similarly can be obtained in one of two ways: (1) using the prescriptive values provided for lag screws for withdrawal and the prescriptive equations for dowel-type fasteners for other failure mechanisms; or (2) by referencing a published test report from ICC-ES.

ASD vs. LRFD Values in the U.S.

In the U.S., two primary structural design methodologies are used:

These two methods produce distinct design values, which are not interchangeable. NDS 2024 (Table 11.3.1) provides adjustment factors for both ASD and LRFD values.

Design Values in MTC Solutions Documentation

At MTC Solutions, we simplify design value integration into Canadian (CSA O86:24) and U.S. (NDS 2024) design standards through our country-specific Structural Screw Catalogs:

Specified resistance values can be input directly into CSA O86:24 factored resistance equations.

Reference design values are ready for use with adjustment factors in NDS 2024 to obtain allowable (ASD) or design (LRFD) loads. Both ASD and LRFD fastener strength properties are provided, with metal strength properties already configured without needing additional adjustment factors.

This “plug-and-play” solution streamlines the design process while ensuring compliance with local standards.

Our approach combines rigorously tested, local regulation-compliant design values with straightforward guidance for application, giving designers confidence in their decisions.

If you have any questions, our Technical Support Team is always ready to assist 😉

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.