ASSY self-tapping screws are widely used in mass timber applications including lateral connections. Connections using self-tapping screws loaded laterally include but are not limited to CLT butt joint or CLT lap joint connections, beam hanger systems and tension straps. Within these connections, a screw can be loaded in shear or inclined towards the shear plane, where the screw is loaded axially. This blog post will discuss the advantages of using inclined screws in lateral connections and will explain the process of designing these connections through example calculations of a simple wood-to-wood connection using USA design codes and the MTC Solutions Structural Screw Catalog.

Approximately 10-minute read.

Lateral connections where screws are loaded in shear are simple to design and assemble, achieving high strengths while remaining ductile. However, it is possible to increase the capacity and the stiffness of a screwed connection by inclining the screws to the shear plane. This can be beneficial in situations where deflection must be limited. By sufficiently inclining the screw towards the shear plane (typically between 30° to 45°), lateral connections can be predominantly characterized by axial effects rather than dowel effects.

Fully threaded screws are optimized for axially loaded configurations and can produce high strengths when used in connections. For example MEGANT Beam Hanger Systems take advantage of the increased strength and stiffness of inclined screws, reliably pushing the connectors to higher capacities.

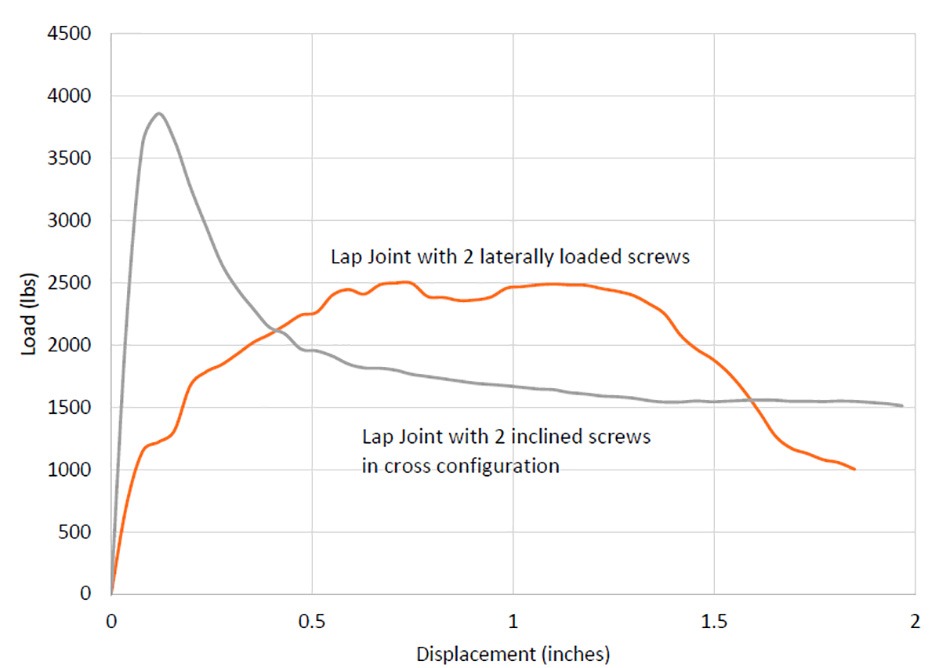

The following graph summarizes research at The University of British Columbia demonstrating that a CLT lap joint designed with fasteners inclined at 45° to the shear plane in a screw cross configuration will have significantly higher fastener yield points than a connection designed with screws loaded only in shear (oriented 90° to the shear plane). Additionally, inclined screw configurations provide stiffer connections due to the decrease in elastic deformation. By understanding the behavior of ASSY screws in both inclined and 90° orientation, it is possible to utilize both configurations in combination to create a high capacity connection with a well-defined and predictable ductile region.

Load Displacement Curves of Lap Joint Connection with ASSY Self-tapping Screws

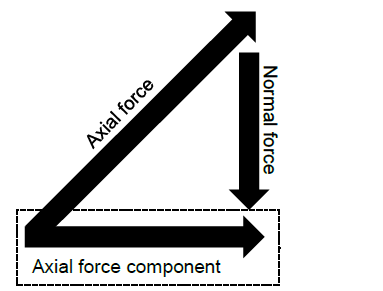

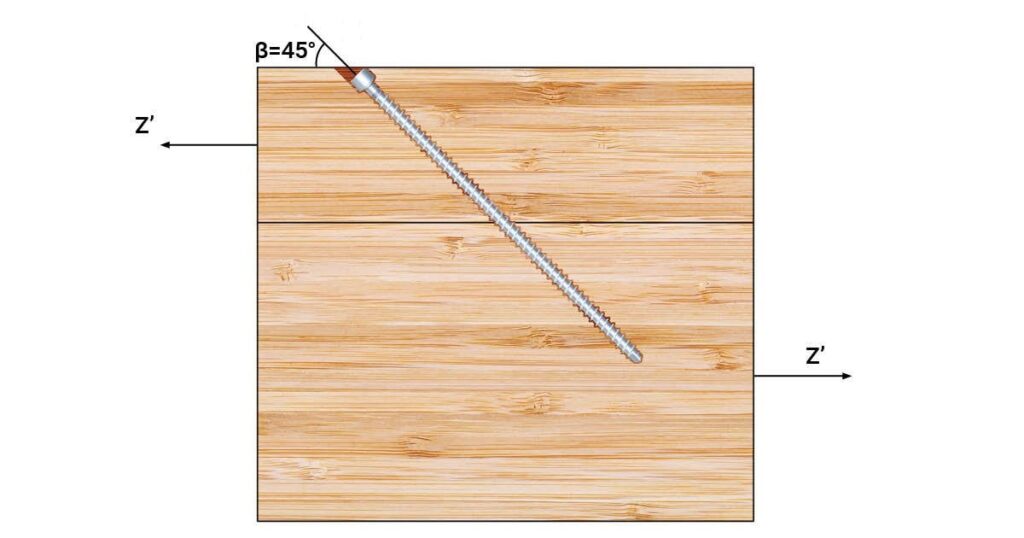

Calculating the design capacity of inclined screw connections is done by utilizing the simplified truss model shown below. The truss model is based on the idea that all design strength can be considered as the product of axial effects only, and that dowel effects can be neglected for the sake of practicality. For more design information on ASSY self-tapping screws, refer to MTC Solutions Structural Screw Catalog.

The following example will go through calculations of an inclined axially loaded screw with appropriate geometry requirements placed 45° to the shear plane. The ultimate capacity of an inclined fully threaded screw, Z, will be limited by withdrawal in the side member, withdrawal in the main member or screw tensile fracture.

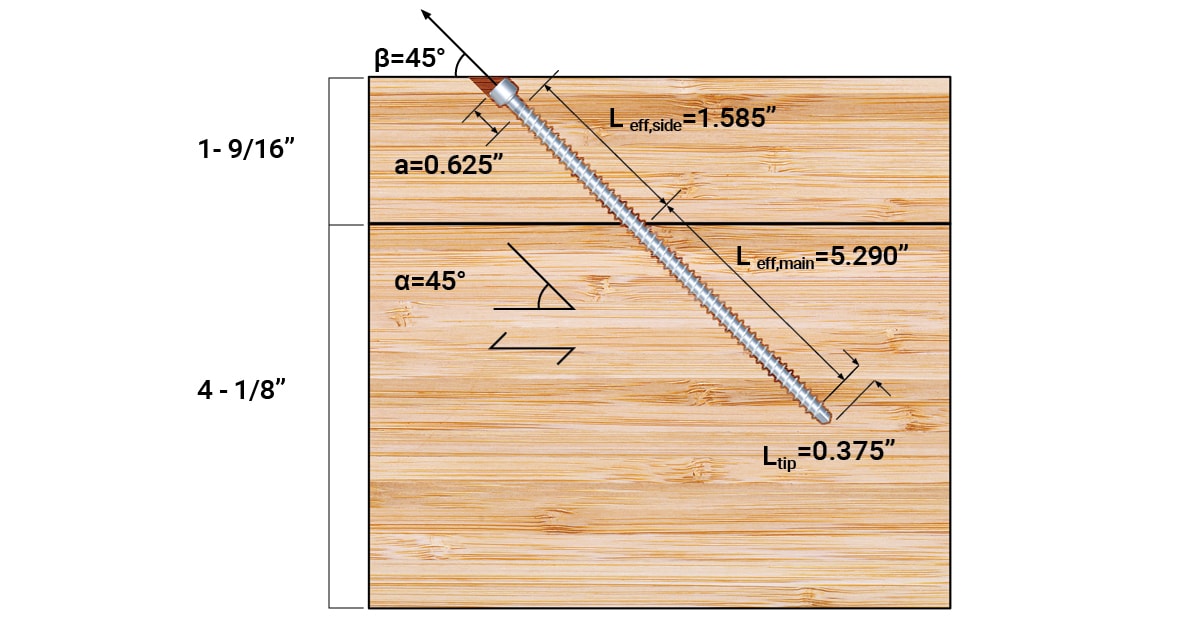

In this example, the following geometry and conditions are considered.

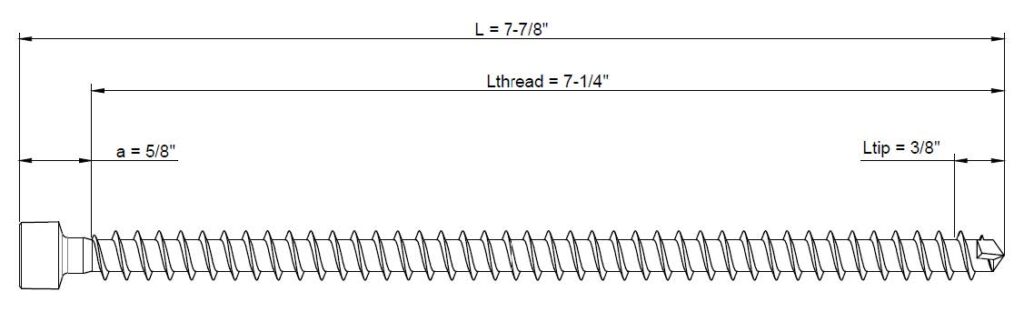

Screw, 1 piece* of ASSY VG Cyl 3/8 x 7-7/8”

* Note that a load bearing connection shall consist of at least two 2 screws

Wood material,

Adjustment factors,

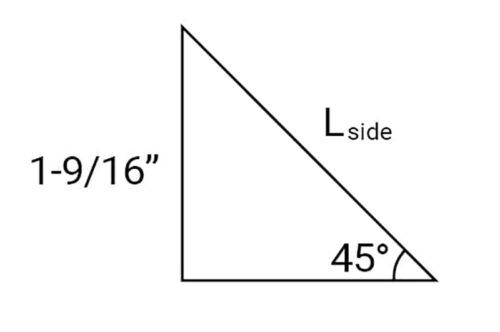

1. Total length of screw in the side and main members

First, the total screw length in each wood member is calculated,

Lmain = 7.875 – 2.210 = 5.665″, screw length in the main member including screw tip.

2.Find W’side withdrawal resistance in side member

Inclined screws utilize withdrawal capacity. The adjusted withdrawal resistance calculation in the MTC Solutions USA MTC Solutions Structural Screw Catalog

can be used with an Angle to Grain Reduction Factor for Withdrawal (R𝛼) equation to account for screw inclination,

W’side = W90 ✕ R𝛼 ✕ Leff,side

W90 = 237 lbs/in, Reference withdrawal design values for withdrawal at 90° angle to the grain, from the MTC Solutions USA MTC Solutions Structural Screw Catalog

Table RDV.1.1, relates to specific gravity of specified wood species.

𝛼 =45°, representing angle between axis of screw and direction of wood grain(𝛼 ≥ 30°). Using MTC Solutions USA MTC Solutions Structural Screw Catalog. Table RDV.1.2, 𝛼=45° corresponds to R𝛼 = 0.857. This represents the angle to grain reduction factor for withdrawal, which reduces the withdrawal resistance of self-tapping wood screws according to the insertion angle to the grain orientation.

The effective length of the screw head (a) is subtracted from the total screw length in the side member (Lside) to find the effective screw thread embedment (Leff,side) in the side member.

Leff,side = Lside – a = 2.210 – 0.625 = 1.585″

W’side = 237 ✕ 0.857 ✕ 1.585 = 321.9 lbs

3. Find W’main withdrawal resistance in main member

Calculating withdrawal resistance in the main member follows the same process as with the side member. All variables, except the effective length as we are in the main member, will be equal to the one used in step 2.

W’main = W90 ✕ R𝛼 ✕ Leff,main

The effective length of the screw tip (Ltip) is subtracted from the total screw length in the side member (Lmain) to find the effective screw thread embedment (Leff,main) in the main member.

Leff,main = Lmain – Ltip = 5.665 – 0.375 = 5.290″

W’main = 237 ✕ 0.857 ✕ 5.290 = 1074.4 lbs

4. Find Z, allowable axial resistance of a shear-tension screw

Now, compare component capacities as below. Allowable tensile strength of ASSY screws can be found in the MTC Solutions USA MTC Solutions Structural Screw Catalog.

Table RDV.3.1.

5. Find connection shear capacity, Z’

The final step is to find the connection capacity in shear by taking a simple component resistance.

Z’ = Z ✕ nF ✕ nR ✕ C’

Since only one screw is used in this example, nF = (n0.9, 0.9n) = 10.9 = 1

For this example, adjustment factors all equal 1, C’= CD CMCtCegCtn =1

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.