Safety and efficiency are key to successful rigging. To avoid issues and keep operations running smoothly, proper checks are essential at every stage of a lift. Whether you are just starting out and want to learn the basics quickly, or you are a veteran looking for field-proven tips to enhance your workflow, this quick guide has you covered. Read on to discover the critical steps you can easily follow to ensure a worry-free rigging process. Also, be sure to check out our Rigging Design Guide for more information.

Approximately 5-minute reading time.

MTC Solutions rigging devices are designed for use with our ASSY self-tapping screws and RW driver bit, following the installation procedures outlined in our Rigging Design Guide and previous article, “Rigging Device Installation: Essential Tools and Top Tips.” The capacity and safety of these anchors cannot be guaranteed if there are any deviations in hardware or installation.

A thorough inspection is critical to the success of hoisting operations and the prevention of accidents. To facilitate this process, we recommend the easy-to-follow steps outlined below. Importantly, the inspection must be performed by a rigging professional licensed by the regulatory body of the jurisdiction where the project is located.

(1) Rigging Hardware

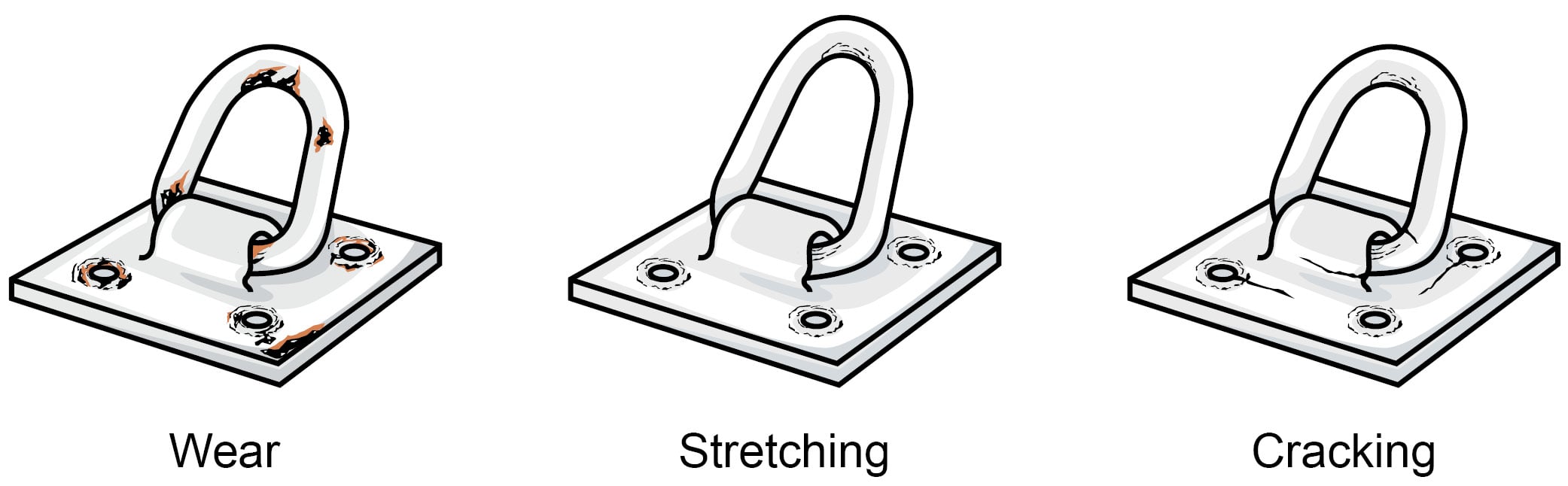

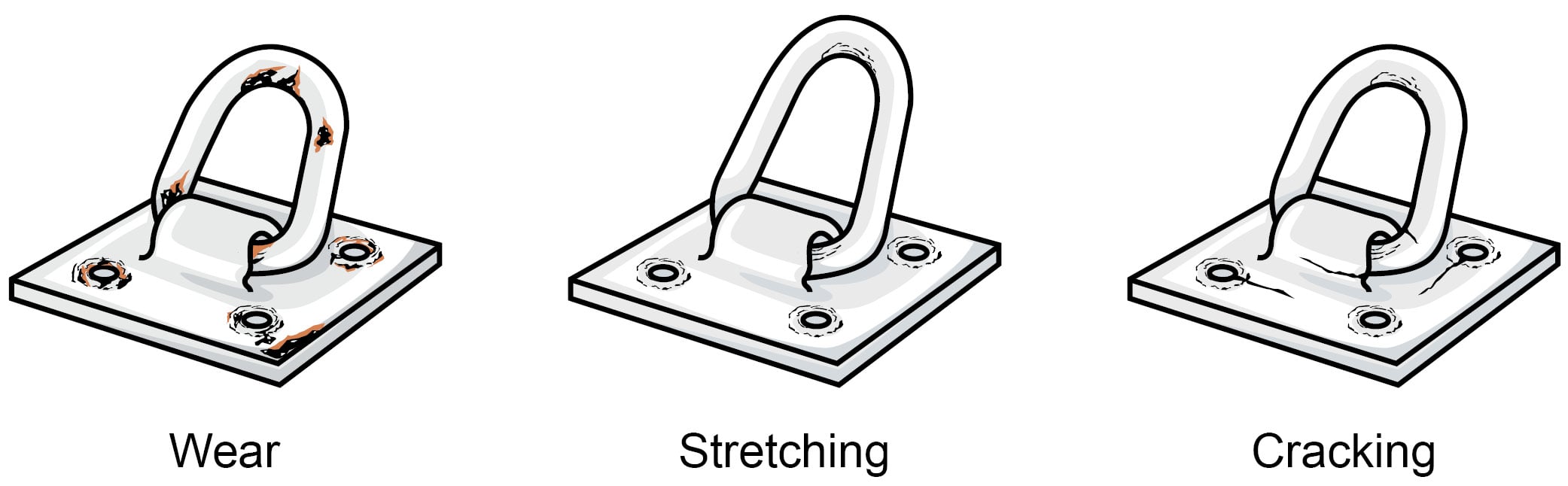

Figure 1. Typical damage on anchors

- Inspect the anchors for visible signs of damage, including wear, stretching, and cracks:

- wear often occurs around the screw holes; and

- remove the anchor from service immediately if there is damage greater than 1/16” in depth.

- Ensure that the screws are brand new:

- screws must never be reused (i.e., reinserted after removal) for rigging.

- Verify that all rigging indicators required by rigging regulations and guidelines are present on the anchors.

- Confirm that the anchors have sufficient load capacity for lifting the construction element:

- load capacity varies with a number of factors, including wood species, sling angle, and screw pattern and type.

(2) Anchor placement

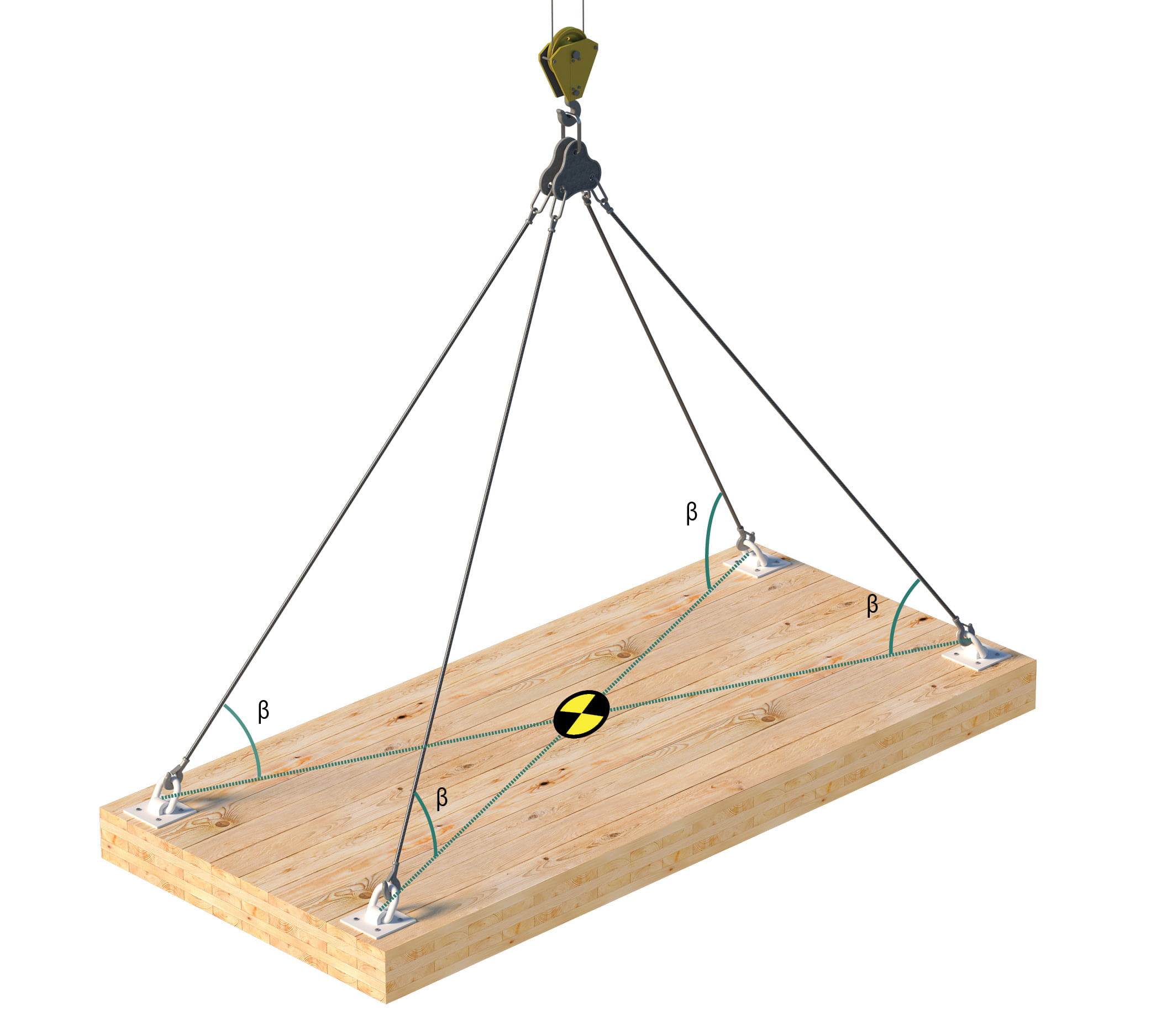

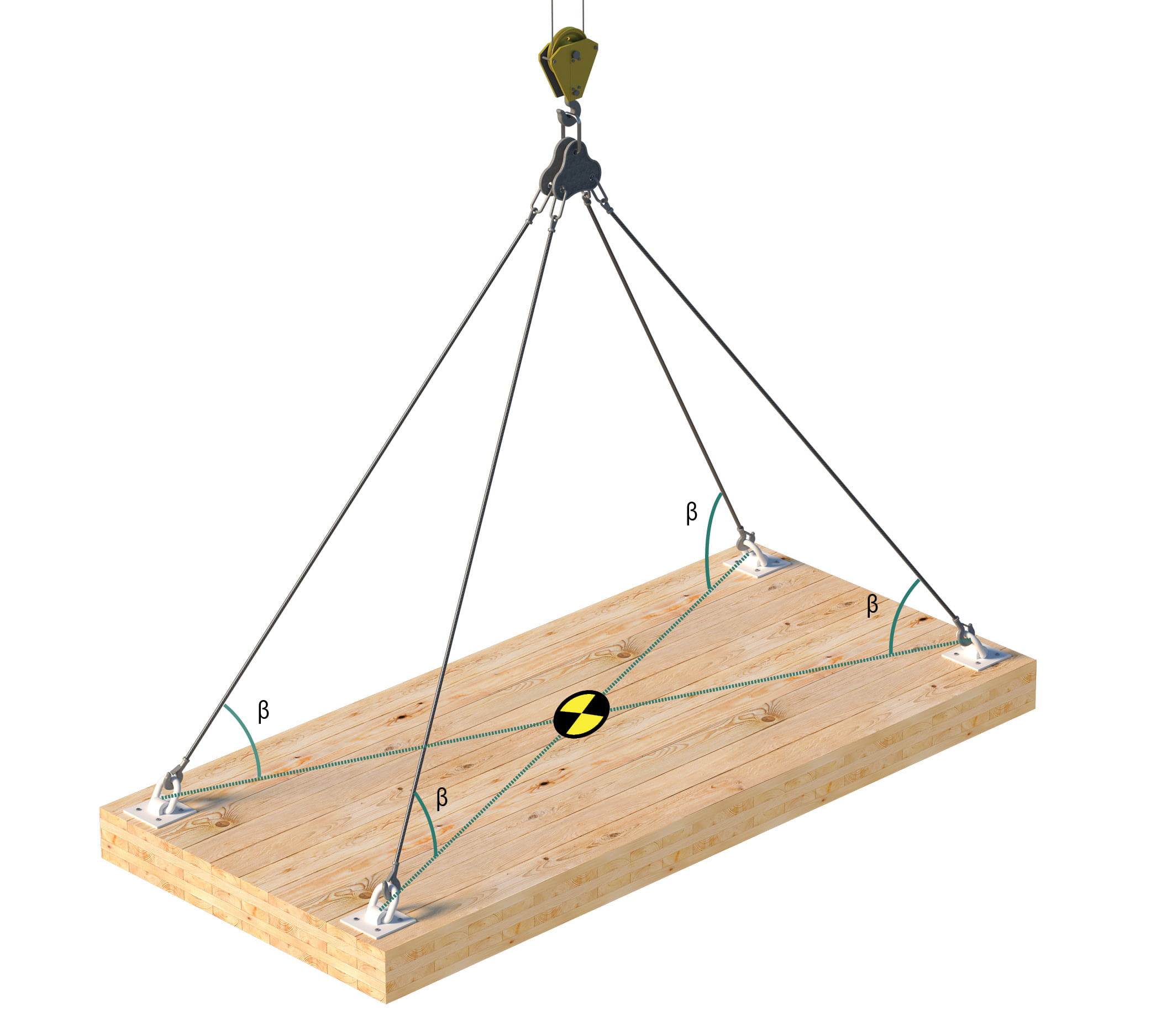

Figure 2. Essential anchor placement: around and above element’s center of gravity

- Ensure that the anchors are arranged around the element’s center of gravity.

- Verify that the anchor placement is above the element’s center of gravity relative to the hook.

- Confirm that the anchor positions allow for alignment between the loads and the slings, as well as free rotation of the anchors.

- Ensure that the sling angle (β), which is the acute angle between the sling and the element surface, is equal to or greater than 60°:

- the load capacity of the anchor decreases appreciably as the sling angle decreases.

(3) Rigging conditions

- Ensure that there is a clear line of communication between the crane operator and the rigger:

- unclear or delayed communication may lead to accidents.

- Recheck for anchor damage:

- damage may occur during installation or transportation.

- Reconfirm that the correct anchors are used, especially in cases where the anchors are preinstalled in the shop.

- Verify that the correct screws have been used to install the anchors by checking their heads.

- Ensure that the screws are not over-torqued:

- over-torquing diminishes load capacity or can cause the screws to break during installation.

- Confirm proper sling attachment.

- Ensure that suspended loads are secured and balanced.

- Ensure that there is no live load (e.g., a person or an unsecured object) on the element during lifting.

- Ensure that no lifting is conducted over persons at any time.

- Confirm that the load is kept under control:

- taglines are recommended for preventing uncontrolled motion.

- Verify that the load is safely landed and properly blocked before unhooking and unslinging the element after lifting.

Following the above steps will help you, as a licensed rigging professional, streamline and enhance your rigging safety checks. If you have questions about our rigging devices or need guidance on rigging planning or on-site support, contact our Technical Support Team.