MTC Solutions beam hanger systems are complete pre-engineered solutions available in a variety of capacities to meet the needs of any building project. These beam hanger systems are commonly used in post-to-beam and beam-to-girder connections to support gravity loads. However, in some applications, these connections may be required to resist uplift forces. This blog post will outline the different solutions that exist to resist uplift in conjunction with the GIGANT and RICON S VS hangers.

Approximately 8-minute read.

The Beam Hanger Systems

The MTC Solutions GIGANT and RICON S VS beam hangers are pre-engineered connection systems consisting of identical plates that slide together, designed primarily to resist gravity loads. Pre-installed in a controlled shop environment and delivered on-site, these connectors allow a simple drop-in assembly and an efficient workflow during installation. To learn more about MTC beam hangers, their different applications, and configuration possibilities, read our related blog post on the subject.

![]()

Figure 1. GIGANT and RICON S VS beam hangers in shop-prepared installations

Due to this straightforward design, the beam hanger plates easily fit together to resist gravity loads but offer no uplift resistance. In most building connection applications, uplift forces can be resisted solely by the weight of the gravity loads, but in some cases, like during construction or in connections with high wind loads, additional resistance may be necessary. The GIGANT and RICON S VS beam hanger systems can be used with one of two solutions, the Clip Lock system, or the usage of fully-threaded inclined self-tapping screws, commonly referred to as “toe screws”.

The Clip Lock Brace System

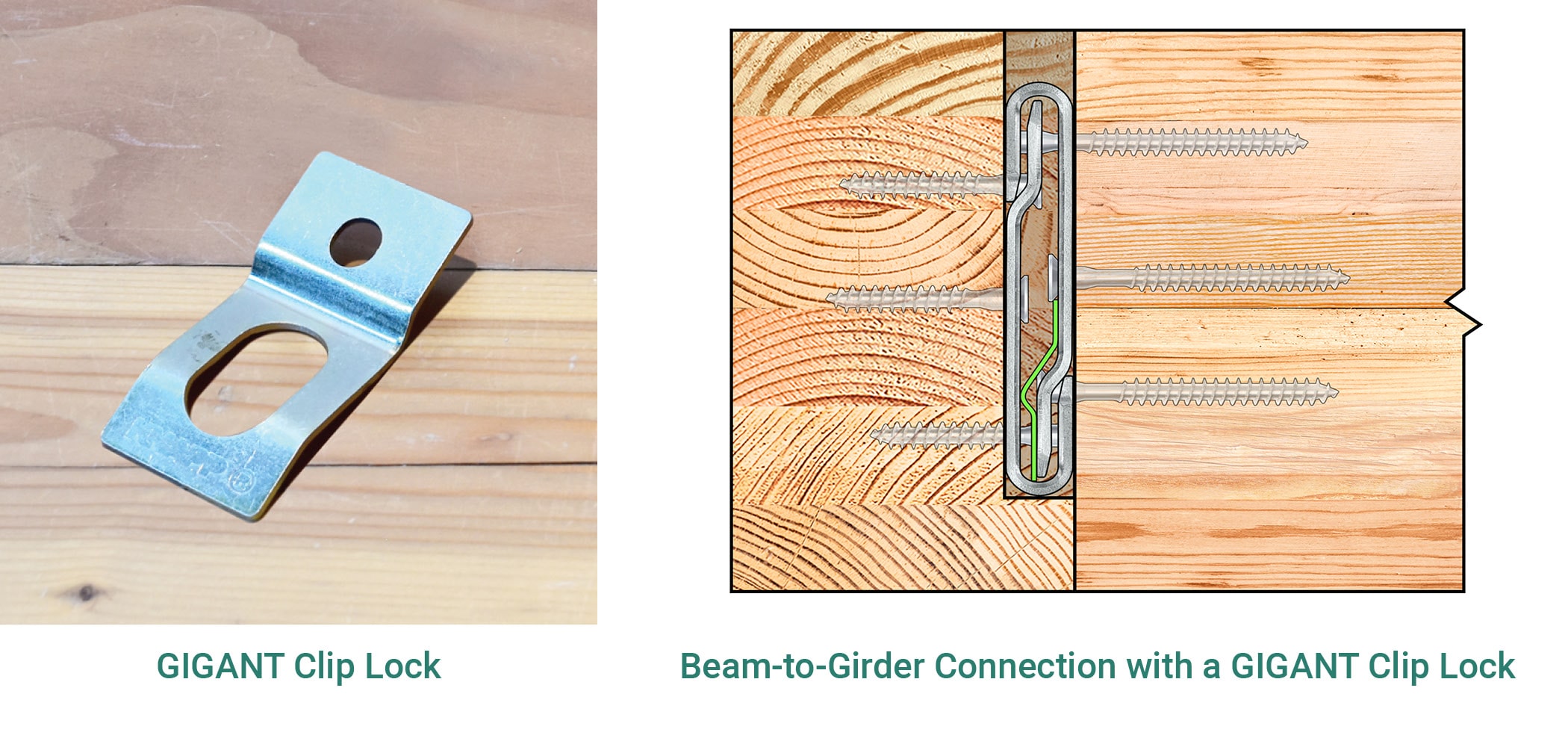

The Clip Lock Systems are additional components available for both RICON S VS and GIGANT beam hangers. They are thin steel plates specially designed to fit into and lock the GIGANT and RICON S VS beam hanger plates together, providing resistance to uplift forces. As the beam is lowered into place, the Clip Lock automatically engages the screw heads on the opposite plate, providing resistance in the upward direction. These components are installed using the same screws used to fasten the beam hanger plates into the wood member.

The GIGANT Clip Lock is installed on the primary member beam hanger plate and must be in place prior to installing the beam hanger’s regular self-tapping screws. Using the Clip Lock in conjunction with the GIGANT hanger will not change the connector’s screw pattern or gravity load capacity. MTC’s Technical Support experts can provide designers with uplift values for the GIGANT Clip Lock system upon request.

Figure 2. GIGANT Clip Lock component (highlighted in green) positioned on the primary member plate

The RICON S VS has Clip Lock models designed to fit either the 60 series (S60) or 80 series (S80). Both the S60 and S80 are made from stainless steel and are installed on the primary member beam hanger plate, prior to the installation of the regular self-tapping screws. Using the RICON S VS Clip Lock will require a slight modification of the screw pattern, reducing the beam hanger’s overall allowable load (in the USA) and factored resistance (in Canada). For more information on this detail, see the RICON S VS Design Information Tables in the MTC Beam Hanger Design Guide.

![]()

Figure 3. RICON S VS Clip Lock models S60 & S80 (highlighted in green) positioned on the primary member plate

Fully Threaded Toe Screws

A straightforward solution for resisting uplift forces is using fully threaded self-tapping screws installed at approximately a 45° angle to the surface of the secondary beam. These inclined fasteners, also known as toe screws, can resist uplift loads through their withdrawal capacity. The ASSY VG CYL excels in this application due to its easily concealed head, high capacity in withdrawal, and simple installation. For Canadian projects, the VG CYL complies with all relevant requirements of CSA O86 for self-tapping screws. In the US, the VG CYL demonstrates compliance with relevant design standards through ICC ESR-3178.

After setting the GIGANT or RICON S VS beam hanger into place, a minimum of two fully threaded VG CYL toe screws are installed at the top of the connection, penetrating from the secondary member into the primary member. If higher uplift capacity is required, more than two screws can be used. Tabulated geometry requirements and capacities for VG CYL toe screws are given in Appendix B of the Beam Hanger Design Guide.

Figure 4. Installation of fully threaded VG CYL toe screws at a 45° angle for uplift resistance

Solution Combination?

Due to a difference in stiffness, the capacity of the Clip Lock solution is not additive with that of fully threaded toe screws for uplift. The toe screws are intended to keep the primary & secondary wood members in place and would prevent slip necessary to fully engage the Clip Lock.

MTC Solutions offers a series of simple options solve uplift design challenges when using Beam Hangers. For more information on these products, download our Beam Hanger Design Guide, which provides further detailed instructions and considerations for designing with MTC Solutions beam hangers and provides additional details on the content mentioned in this blog post.

If you have any questions, contact our Technical Support Team 🙂

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.