Dear Colleagues,

Until recently, North America has seen limited progress in developing design standards for commercial timber buildings. Curiously, even today, we are still dealing with standards that harbor legacy clauses that may, in some respects, appear outdated.

Recent developments have brought to the forefront one of the most advanced design standards for mass timber structures—Eurocode 5 EN 1995-1-1. Following multiple rounds of revisions, this standard has been submitted for public review by the European Committee for Standardization. Within this draft, an array of interesting clauses and suggestions can be found, some of which have particularly captured our attention. We believe that they could serve as a solid foundation for discussions here in North America.

We are sending this letter with the intent of raising awareness on the matter relating to the effective number of fasteners and providing relevant background information.

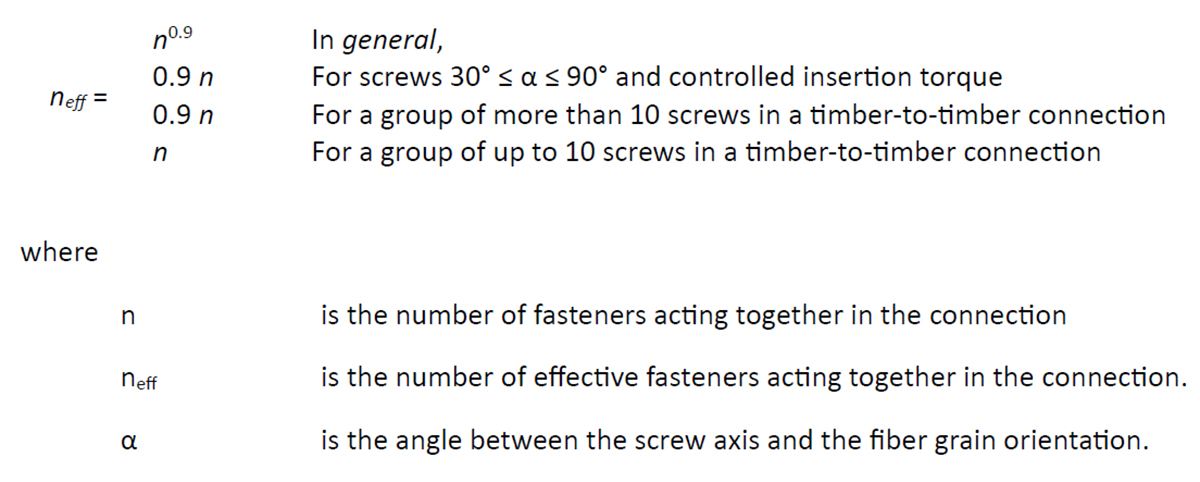

The draft in question distinguishes between axially and laterally loaded fasteners. As similarly emphasized in the guidelines provided by MTC Solutions, these two types of connections exhibit distinct behaviors, thereby requiring separate design considerations. In this instance, we are mostly interested in axially loaded fasteners, including axially loaded inclined fasteners in lateral connections. The proposed provision stands as follows:

We believe that this revised clause offers valuable and intriguing insights, from which we, as North Americans, can glean knowledge. Having taken the time to analyze its meaning and implications, we have arrived at a few conclusions:

This final point, in our view, is of marked importance. This is especially true considering the multiplication of high-capacity connections utilizing axially loaded inclined fasteners as points of attachment, such as beam hangers. Given the current trend towards longer spans and the prevalence of post-and-beam framing systems in the North American mass timber sector, beam hangers must now contend with increasingly heavy loads. It is for this reason that many designers specify custom connectors with fasteners loaded in tension.

High-capacity, critical connections necessitate careful design and installation—a practice firmly established in other industries. Yet, there persists an inherent belief, likely originating from stick frame construction, that abundant redundancy exists in timber buildings. Practical solutions are available now for immediate implementation. For instance, these important connections could benefit from:

These are just a few tips that can be relatively easily applied to avoid heavy penalties on connection resistance.

The time has come for us—engineers, manufacturers, developers, installers, and those committed to leaving a positive legacy—to pay due attention to the installation requirements for key structural connections.

At MTC Solutions, we take pride in supporting our customers and delivering the most practical solutions conceivable. Please do not hesitate to reach out to us for any support that we can provide. It is our hope that this letter will make you think of the importance and care required when working with axially loaded fasteners used in steel-to-wood applications.

Cheers,

MTC Solutions

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.