APEX

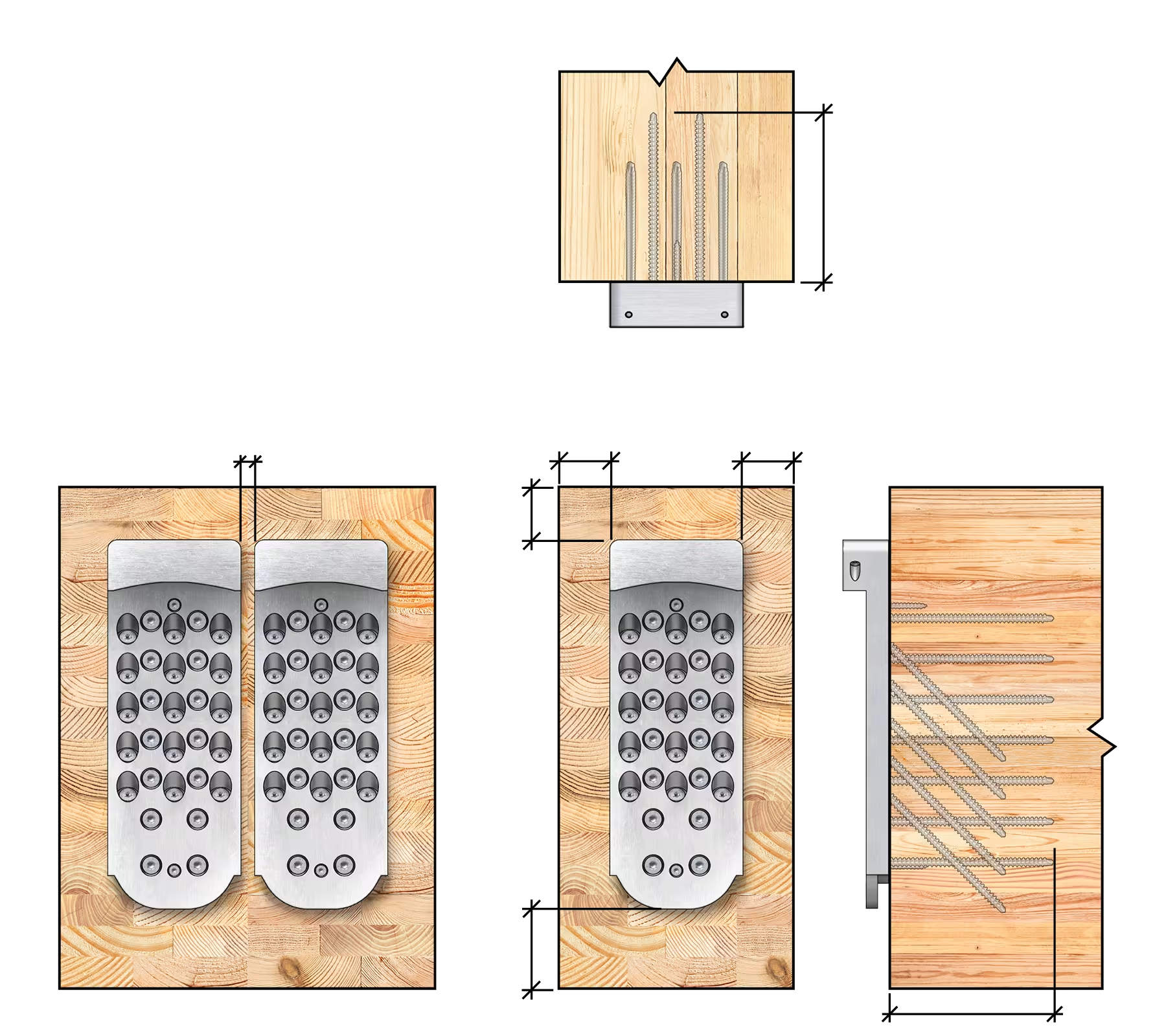

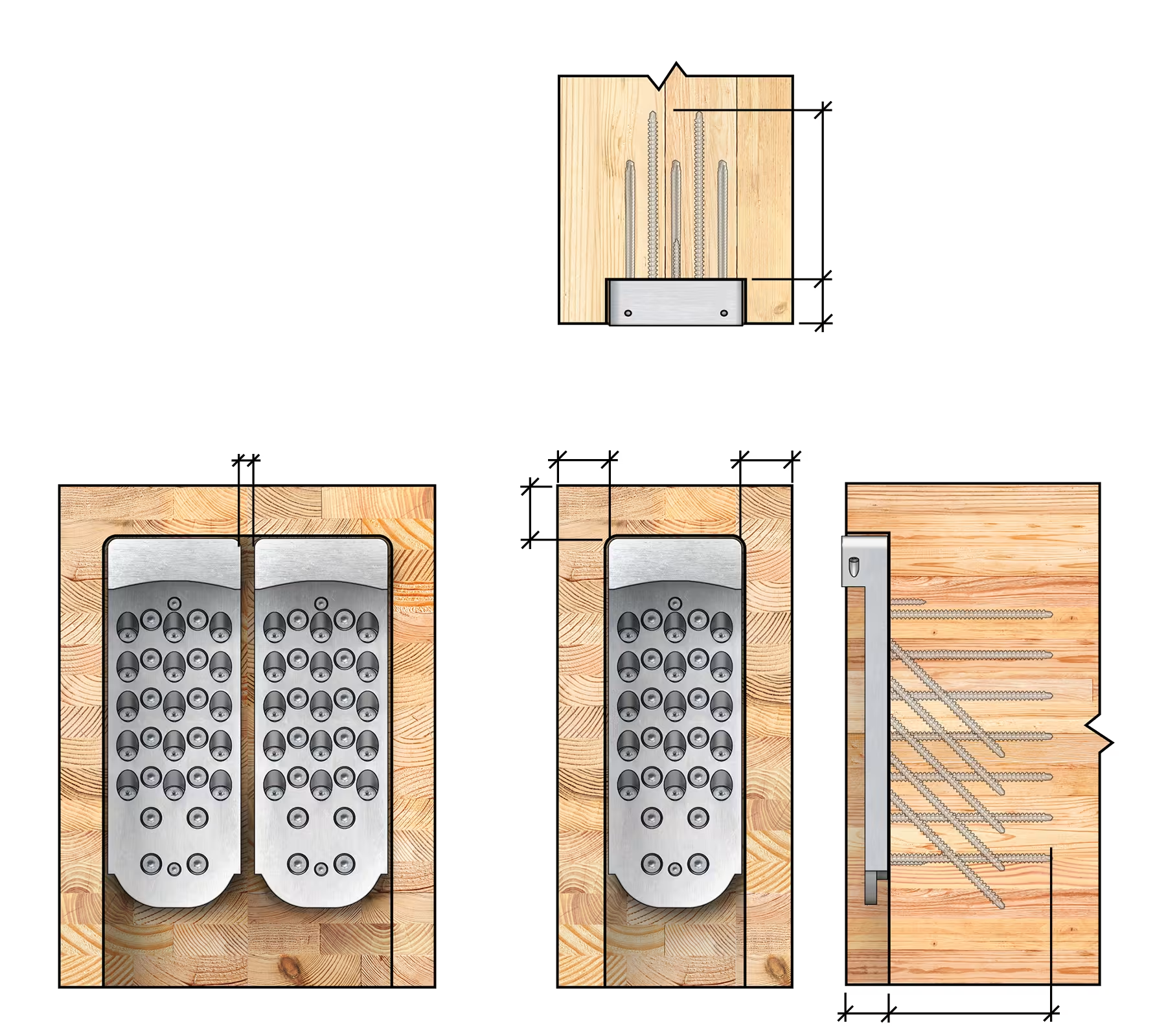

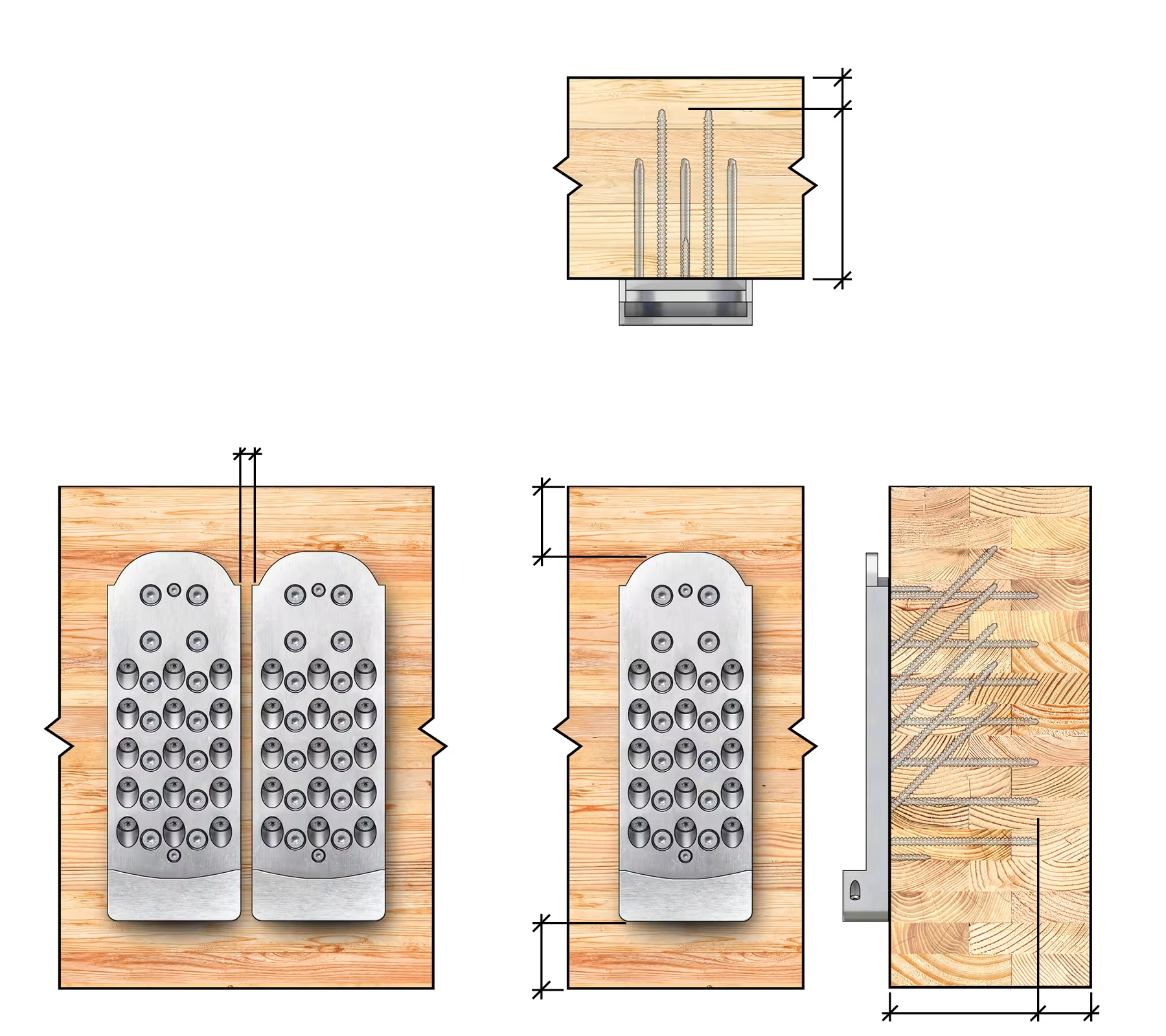

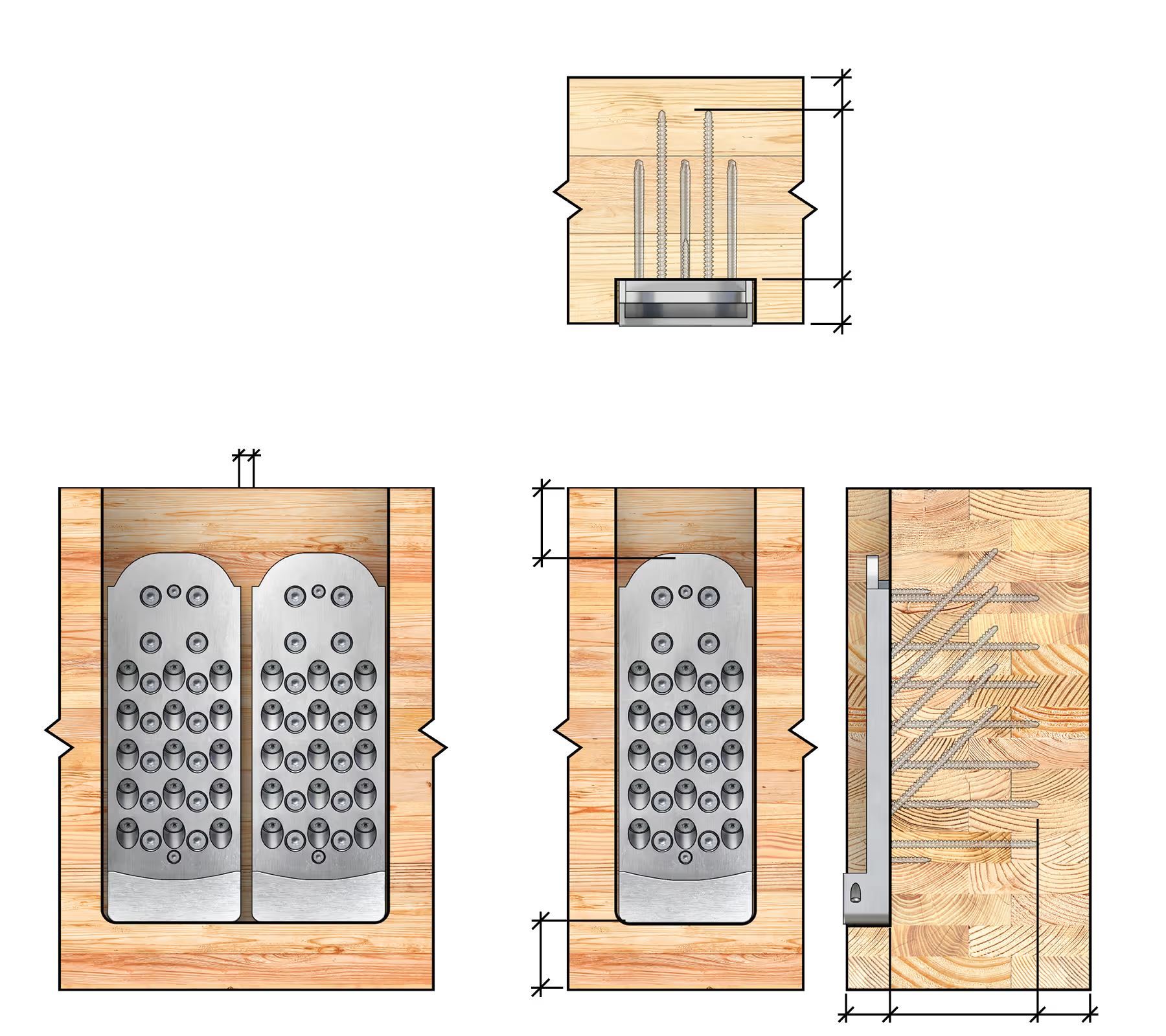

Pre-engineered Connection System

-

Canadian and US Engineered

-

Canadian and US Manufactured

-

Interstory Drift Tested

-

MTC Solutions Owned

-

Download and axially tested

-

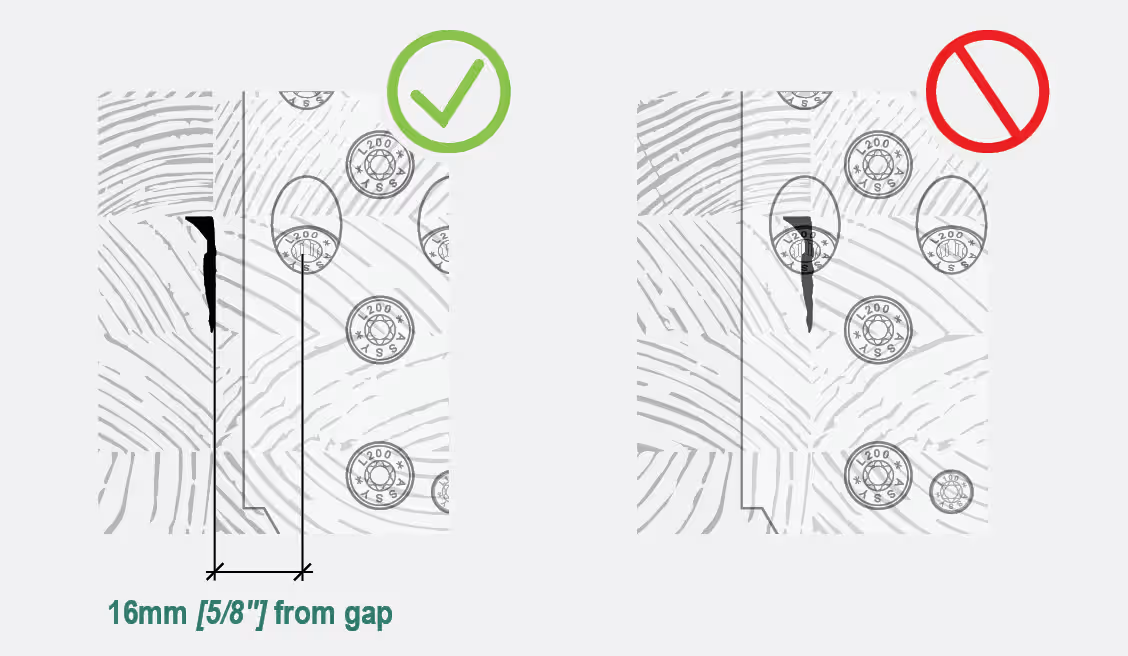

Installation Tolerances up to 1/8" (3.2mm) and 0.5°

Uplift Capacity Range

Uplift Capacity Range  Axial Capacity Range

Axial Capacity Range  Manufactured in

Manufactured in  Material

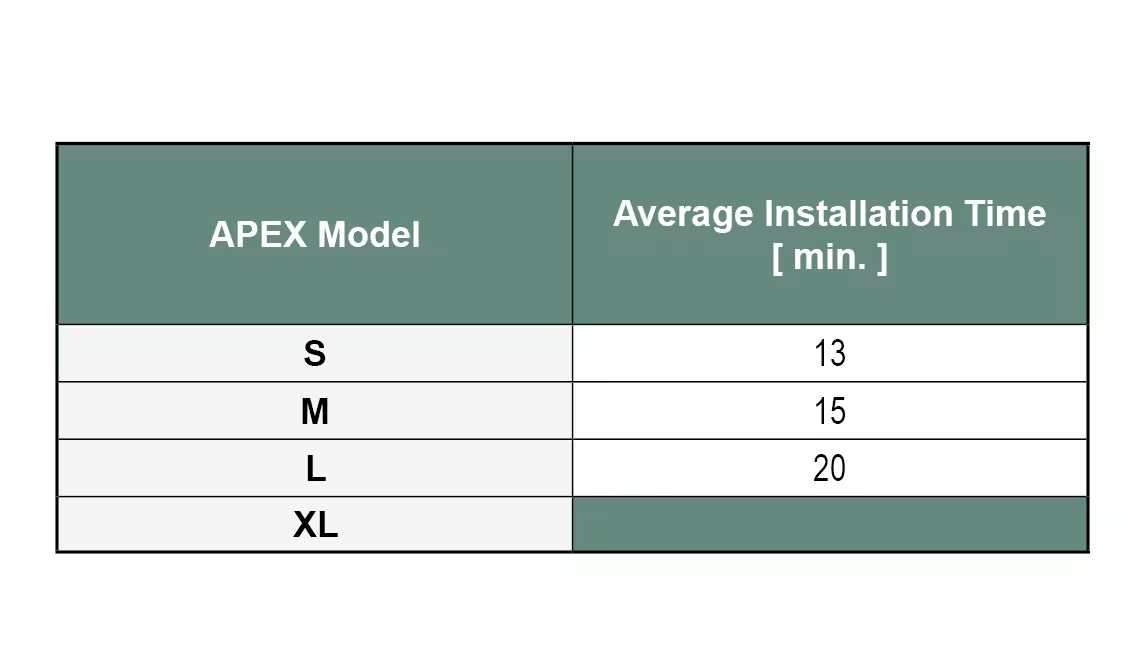

Material  Installation Time

Installation Time

Standard & Certifications

Standard & Certifications  Seismic Compatibility

Seismic Compatibility  Tested Fire Resistance Rating

Tested Fire Resistance Rating

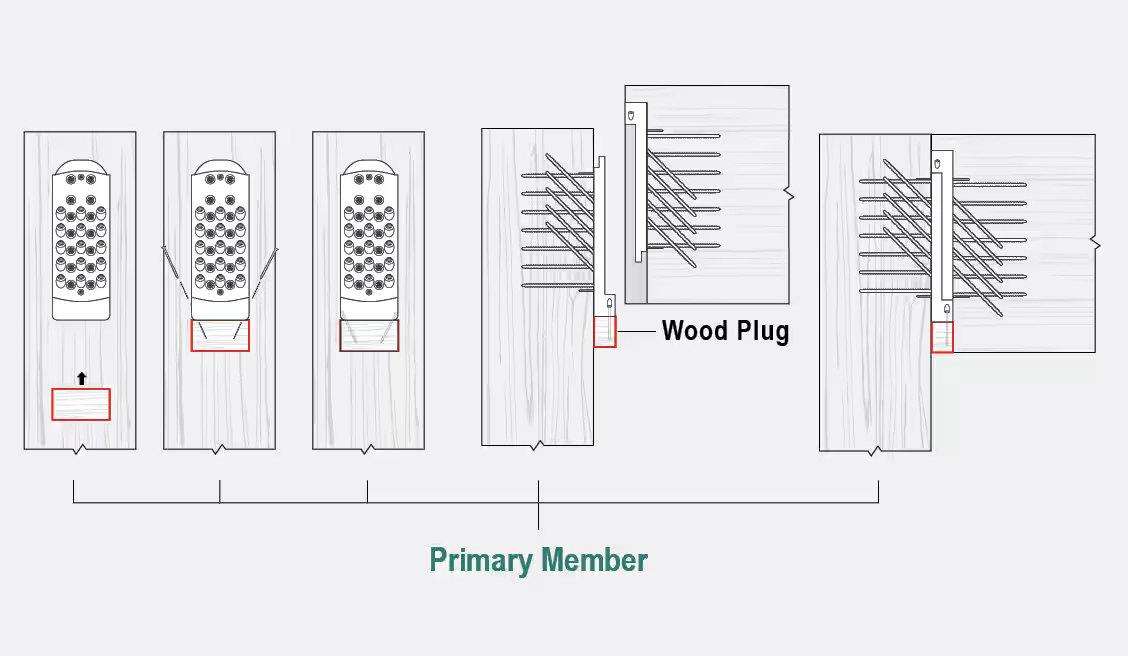

Download Installation Guide

Download Installation Guide

Menu

Menu

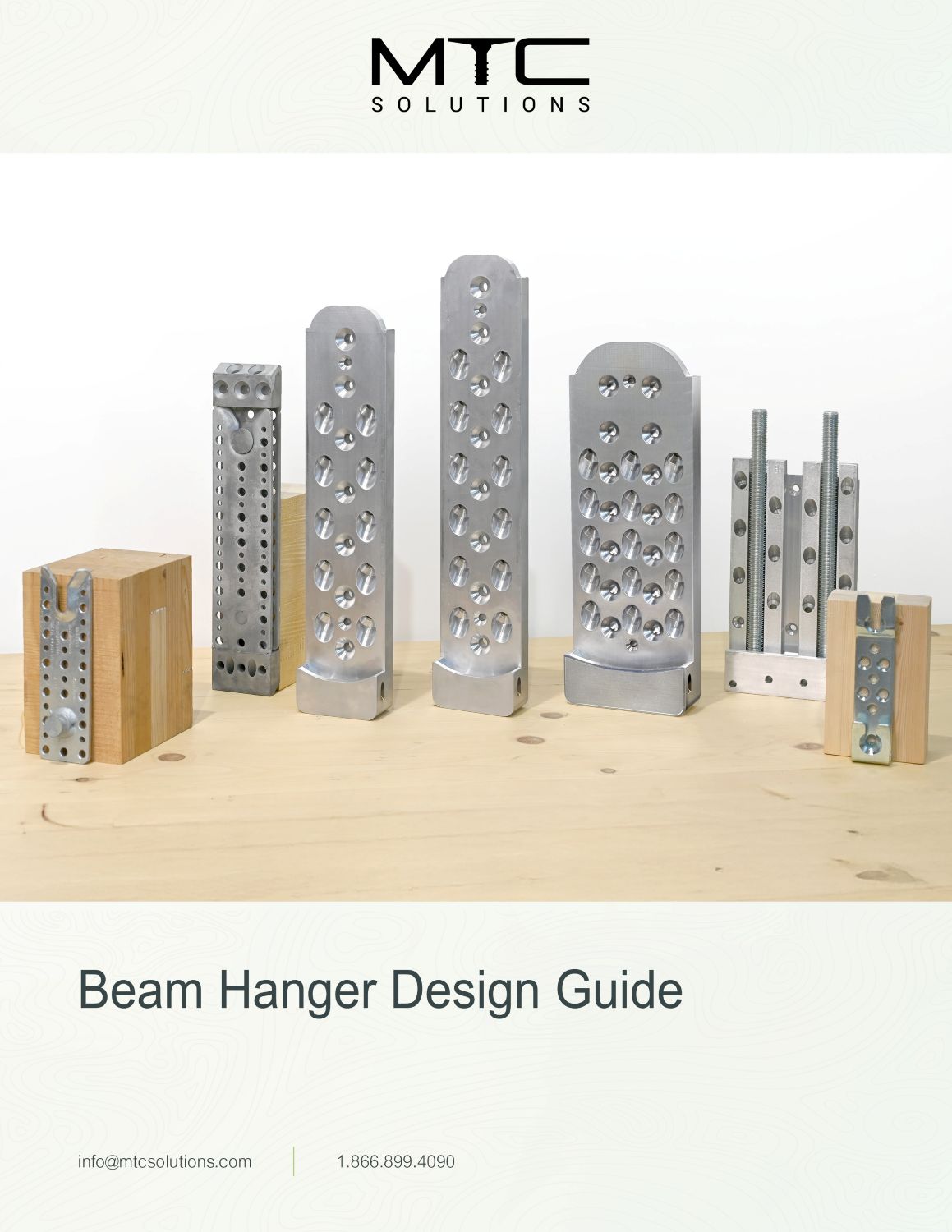

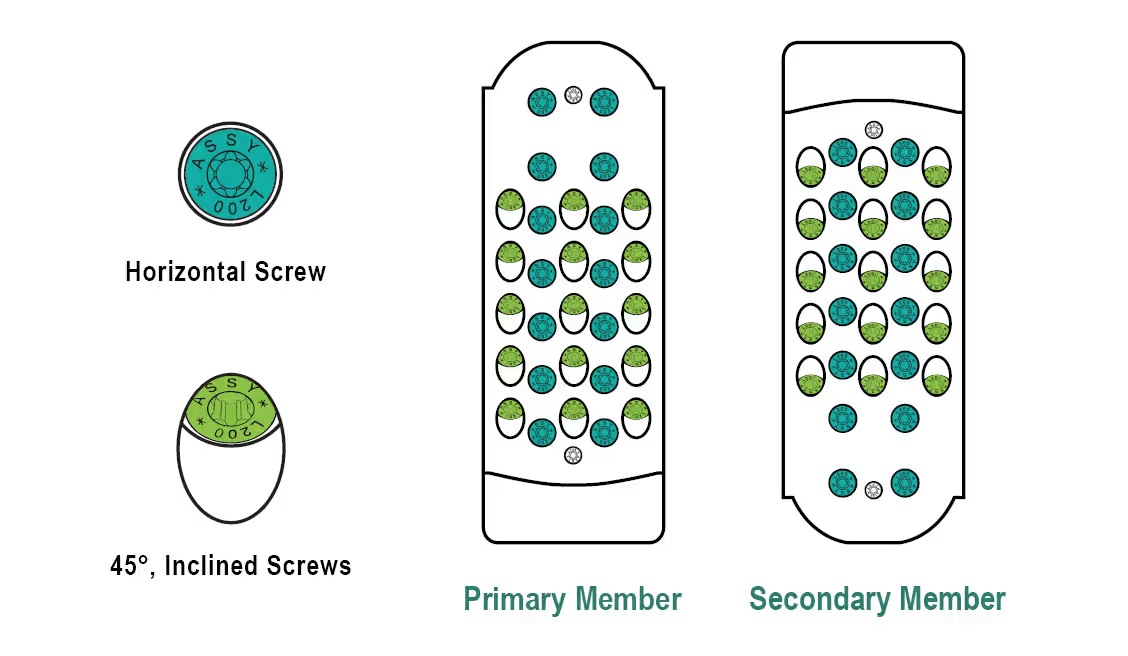

Beam Hanger Comparison

Beam Hanger Comparison

Capacity

Capacity

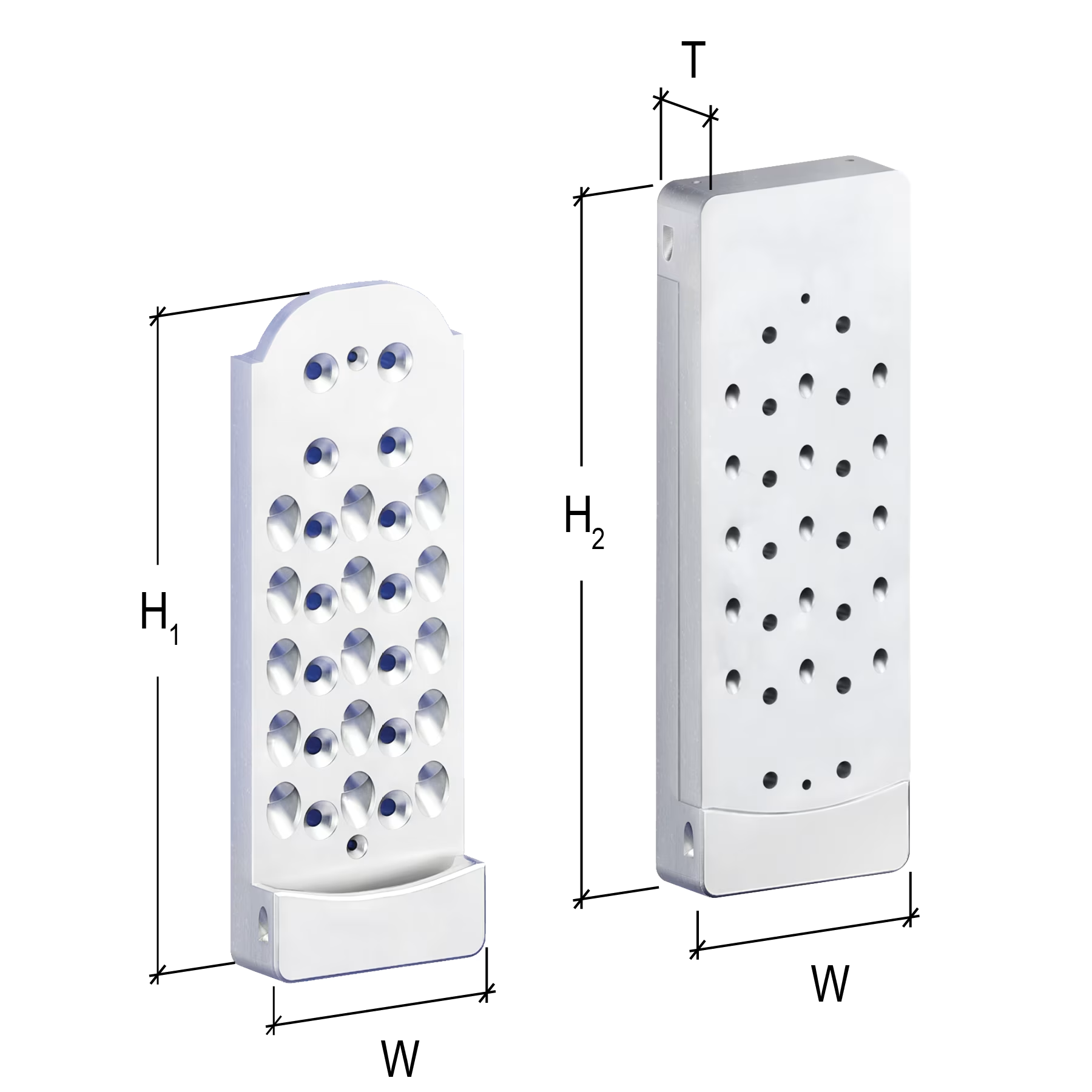

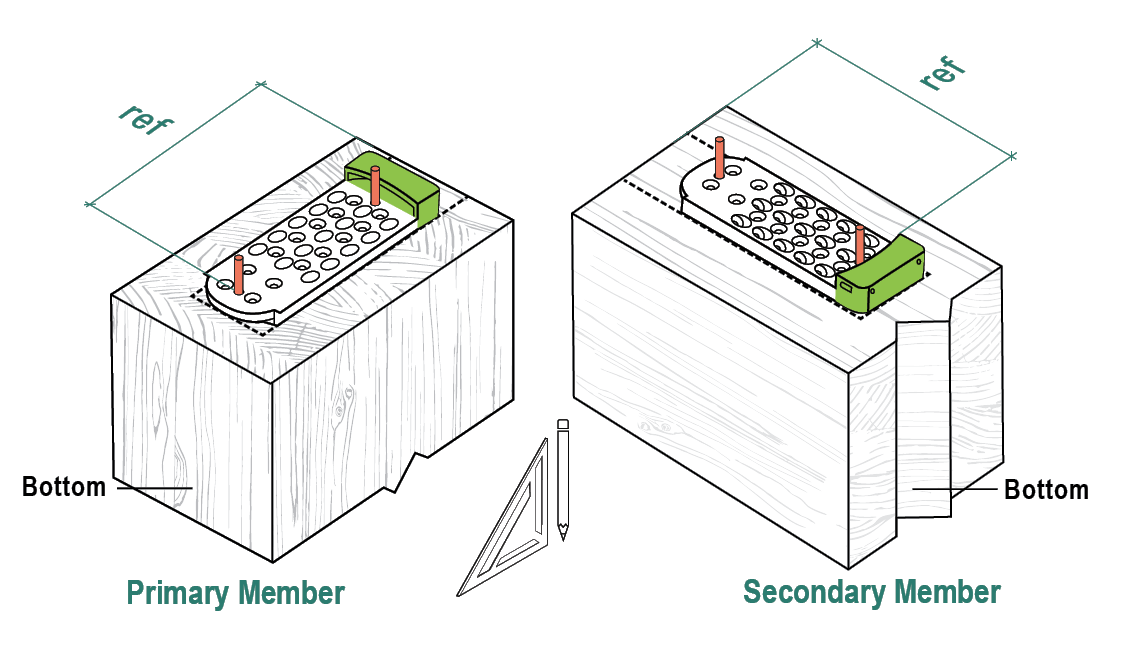

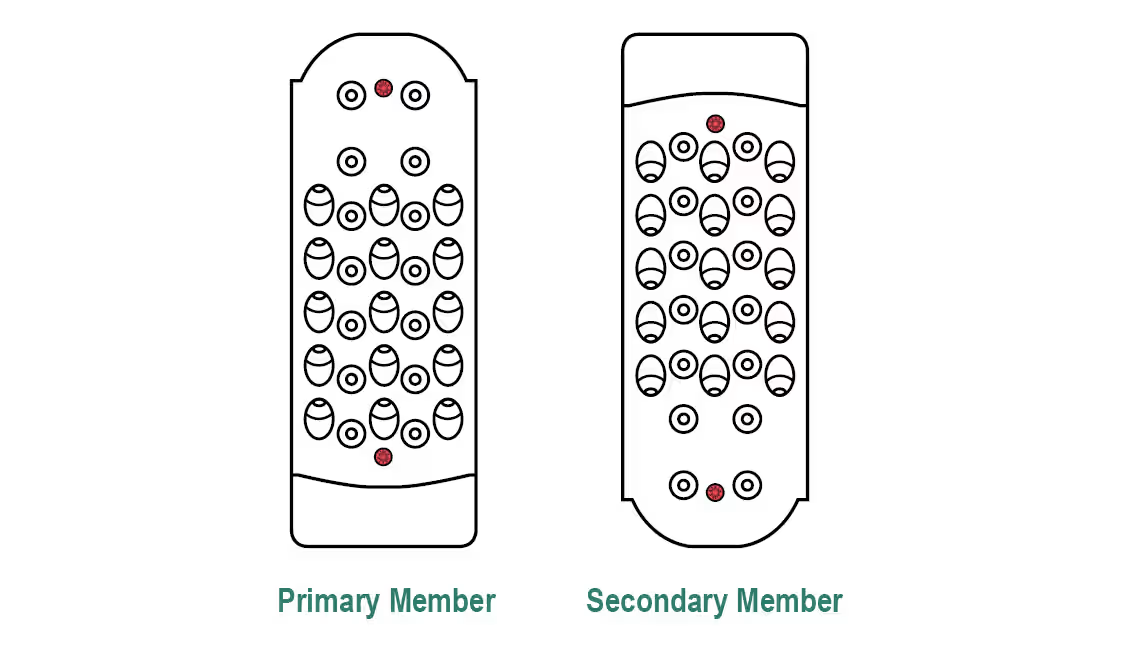

Secondary Member Req's

Secondary Member Req's

Primary Beam Req’s

Primary Beam Req’s

Primary Column Req’s

Primary Column Req’s

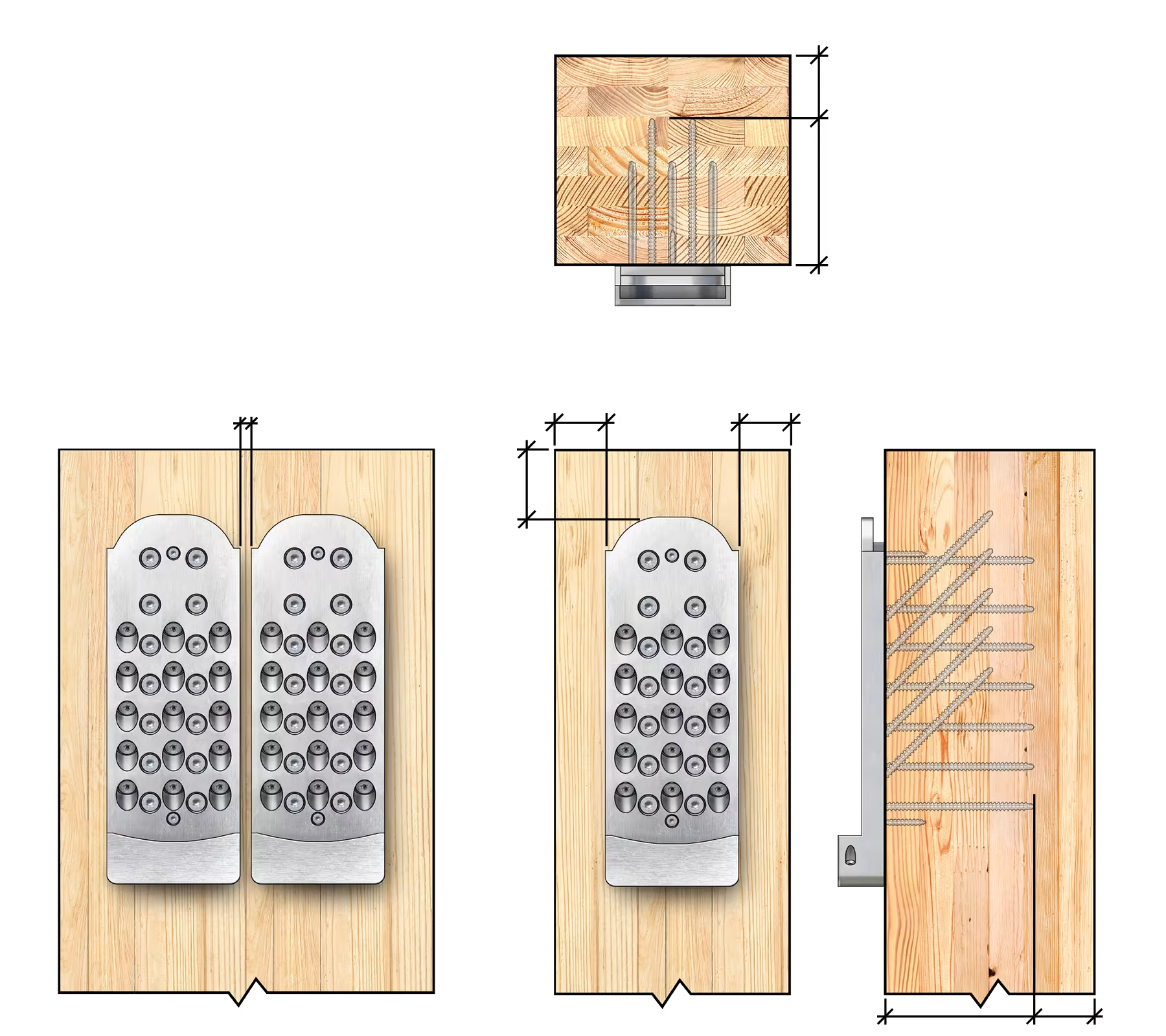

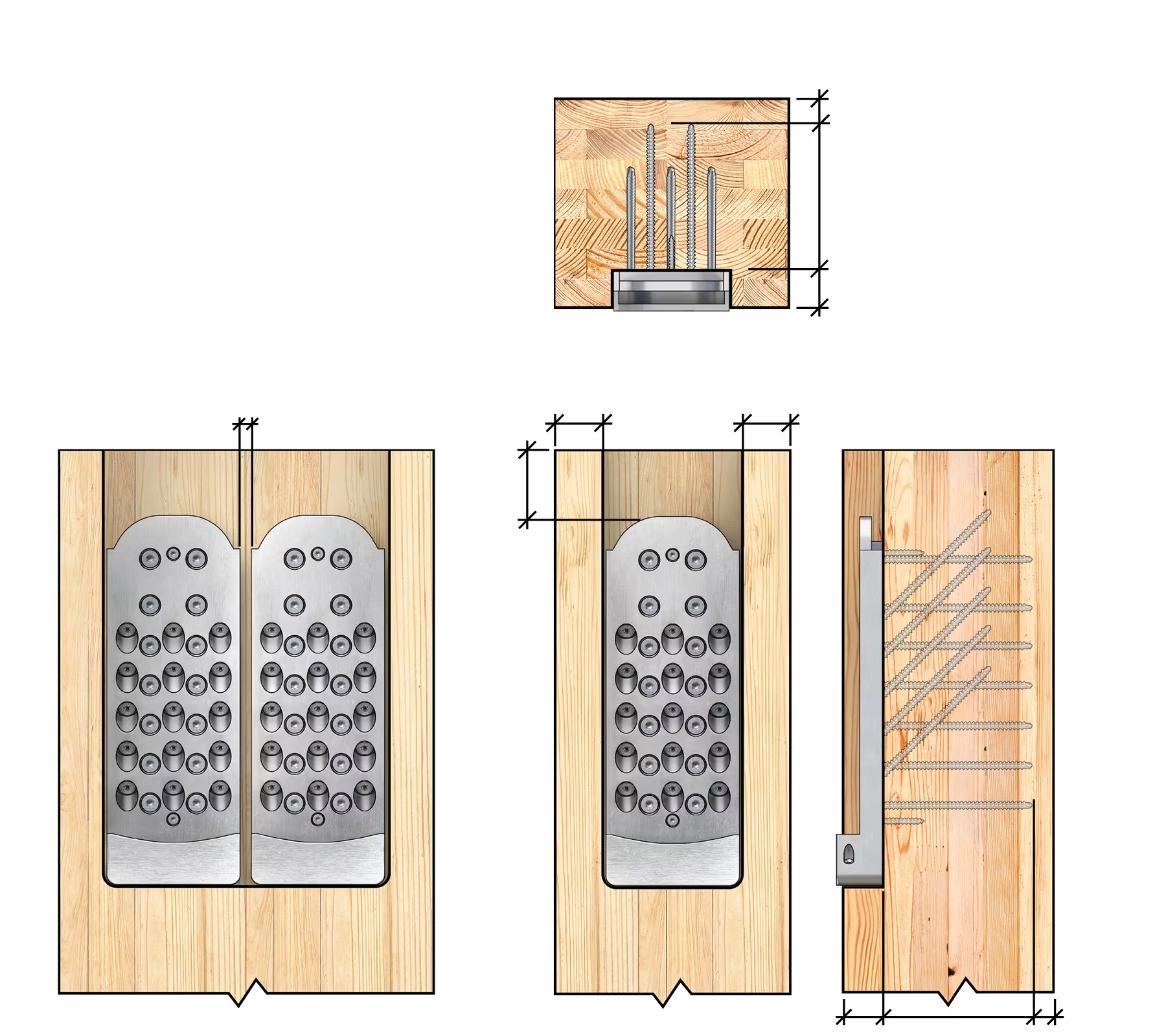

2D & 3D Geometry

2D & 3D Geometry

Design Guide

Design Guide

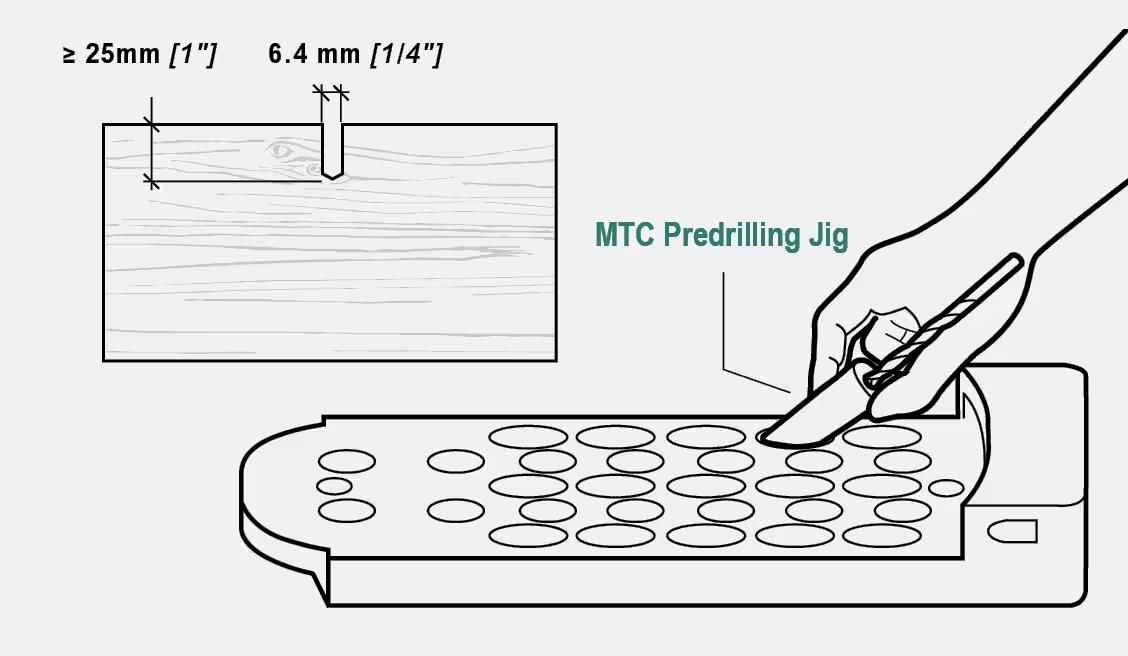

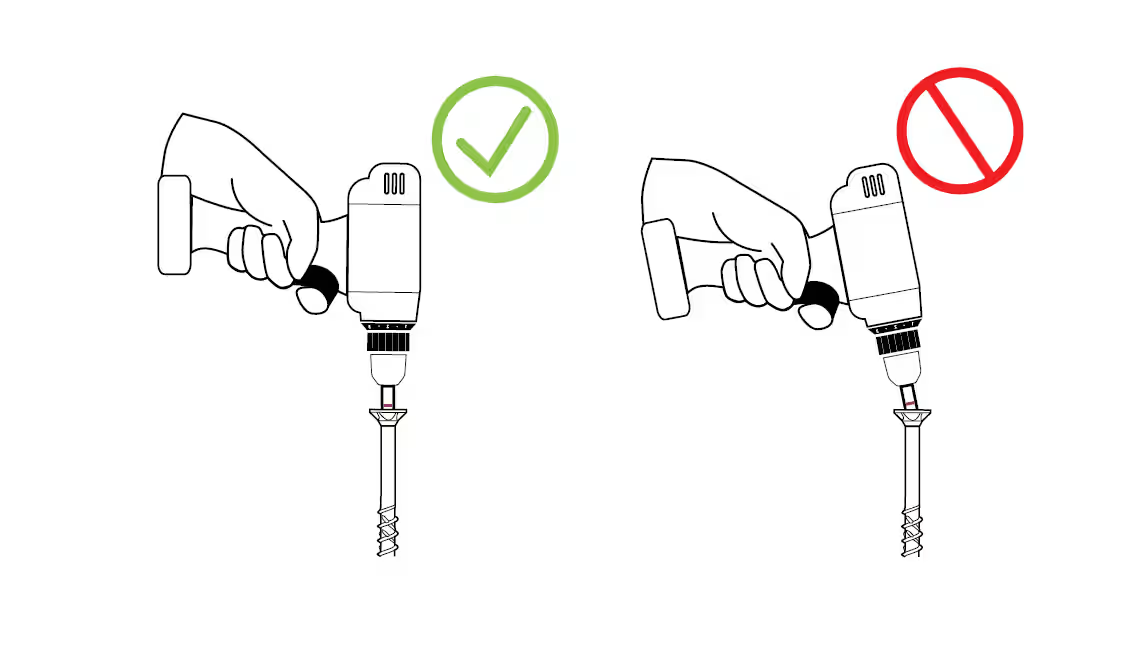

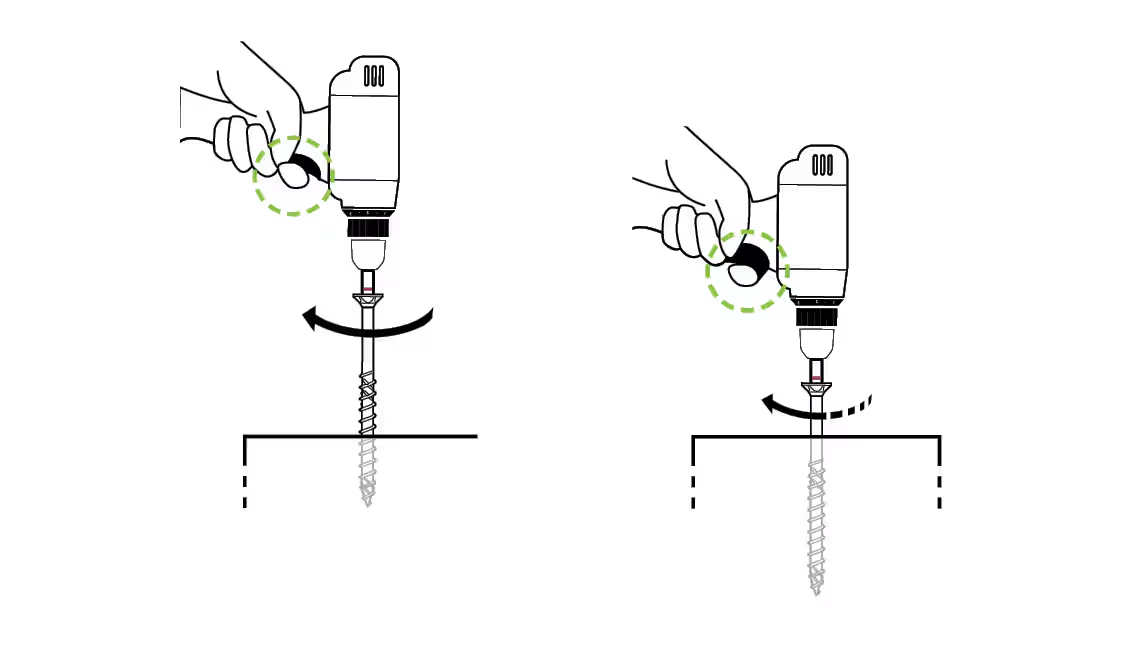

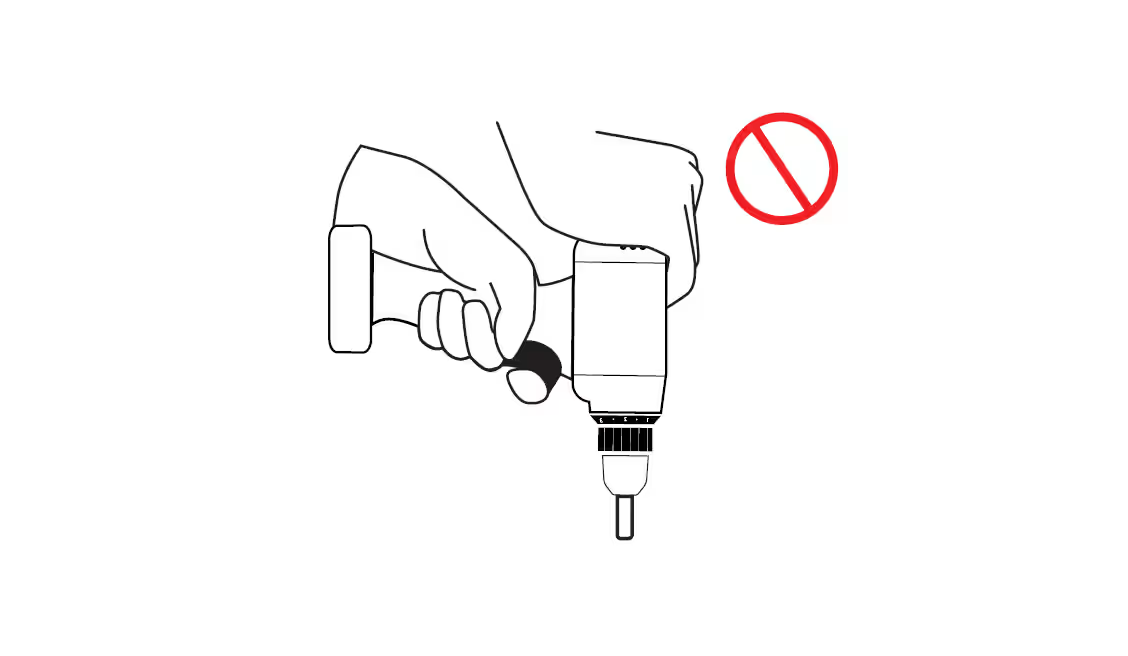

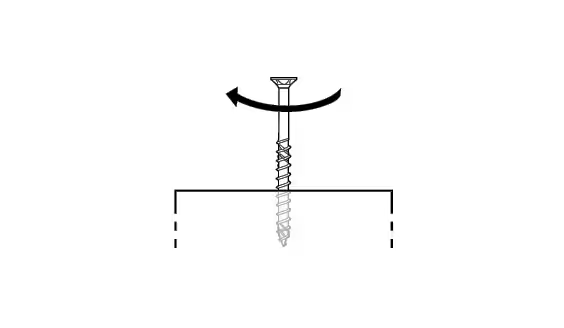

Installation Instructions

Installation Instructions

Tech Blogs

Tech Blogs