There are several options available to detail a steel-to-wood connection using ASSY self-tapping screws. It can be done by sitting the screw directly on the steel plate, by countersinking the screw head into the steel plate, or by installing the screw with a washer. This blog post will summarize these three types of steel-to-wood connections.

Approximately 8-minute reading time.

Screws on Steel Plate, Installed at 90-Degree

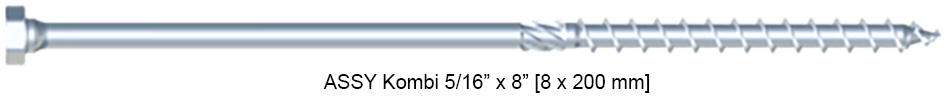

When designing a steel-to-wood connection with fasteners sitting directly on a steel plate, the ASSY Kombi screw with its hexagonal head is ideal. This fastener is specifically designed for steel-to-wood connections. Under the head of the screw, a shoulder of diameter matching the width of the screw thread helps provide a snug fit reducing initial connection slip.

Based on the exact needs of the connection, several other screw options are available. The ASSY VG CSK and the ASSY Ecofast screws are reliable alternatives with a versatile countersunk head shape that can be used in this scenario, as well as be installed countersunk into the steel plate, and installed using MTC’s 90-degree and 45-degree wedge washers which will be explained later in this blog post.

The calculation method presented in the NDS assumes that there is no strength contribution stemming from the end fixity. The convention to ignore the effects of end fixity is justified by the difficulty of quantifying the behavior of generalized connections under the numerous design parameters for all types of fasteners. One of the consequences of ignoring the end fixity is that the yield model presented in the NDS and CSA O86 assumes screws are simply held in place. No matter their head type self-tapping screws are considered as smooth dowels in a shear plane despite testing showing ASSY self-tapping screws provide considerable increases in design strength compared to smooth dowels, but those increases are neglected.

This means countersunk head screws like the Ecofast and the VG CSK screws can be used without washers or countersunk holes in the steel plates with no effects on the design value of the screws.

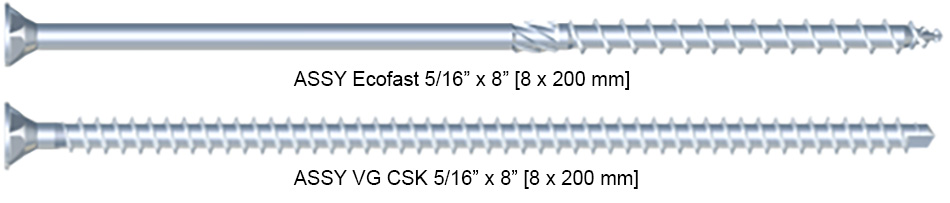

To illustrate the tolerance or space left between the screw and the steel plate, the following figure showcases the fit of all ASSY screw head types in a 1/2″ [12mm] thick steel plate, with the proper pre-drilled holes. All head types available at MTC Solutions were included to show all different options.

Notes: 1. Rendering is to scale with a 5D of spacing in between each screw axis

Inclined Countersunk Head Screws in Steel Plate

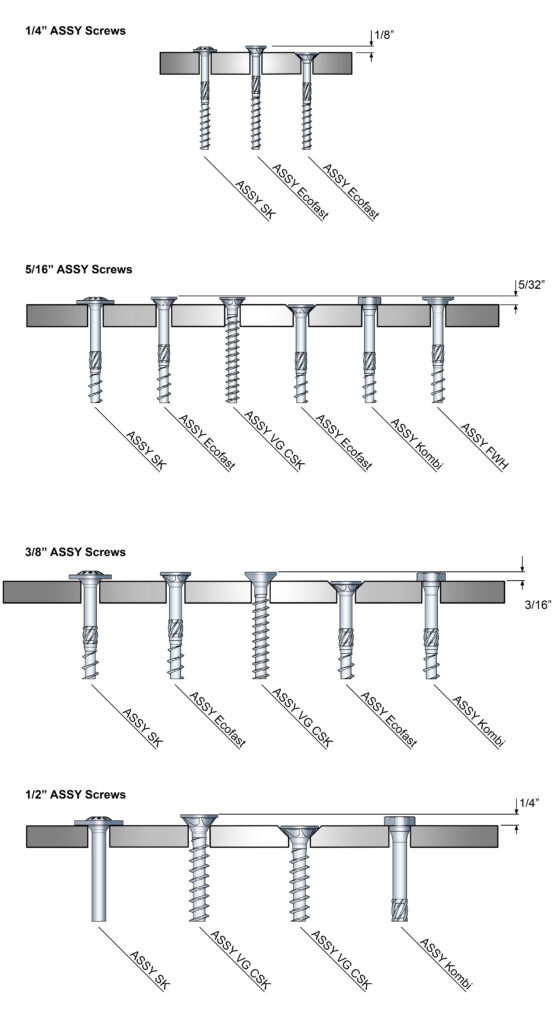

If the design requires countersinking the head of the fastener into the steel plate, the usage of the ASSY VG CSK fully threaded screw or the ASSY Ecofast partially threaded screw is suggested. As shown below, the screw head is completely countersunk within the milled hole.

To completely countersink the screw head, the steel plate must be milled at an appropriate angle and with the right head dimensions. The different screw head dimensions can be found in our Structural Screw Catalog.

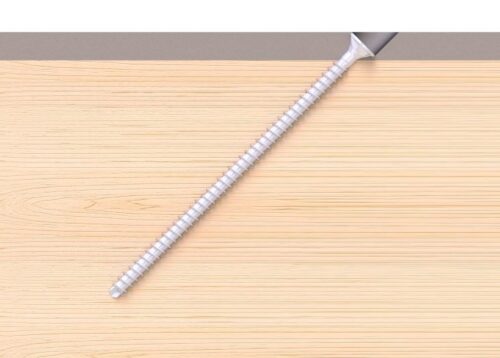

As seen in a recent blog post,ICC-ESR approved 45-Degree Washer Detailing and Installation Tips, MTC Solutions offers an alternative around the complex process of milling for this type of connection, the MTC Solutions wedge washer. MTC’s 45-degree wedge washer can be used to achieve an inclined steel-to-wood connection, typically used with the VG CSK for axially loaded inclined screw connections.

These washers help in the installation of the screw by providing the correct angle for installation and provide enough bearing for the screw head while reducing the thickness of the steel plate used. Installation with the washer is simple as they only require a punched hole in the steel plate. In contrast, milling the steel plate at an angle to accommodate the screw head may be more difficult. Washers in steel-to-wood connections offer a more cost-effective solution compared to milling the steel plate to house the screw head.

Steel Plate – Pre-Drilling Requirements

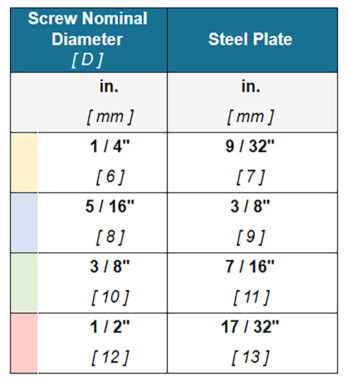

Finally, when using self-tapping screws with steel plates, the steel side member must always be pre-drilled with the proper sized hole prior to the installation of the screws. The pre-drilled holes for ASSY self-tapping screws depend on the diameter of the screw used. The following table, from our Structural Screw Catalog, summarizes the pre-drilling requirements in steel plates for several screw diameters.

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.