Cost comparison between different fastening technologies must consider the entire picture to have any relevance. A fastener-to-fastener cost comparison leaves out important information that affects the total cost of the connections, including:

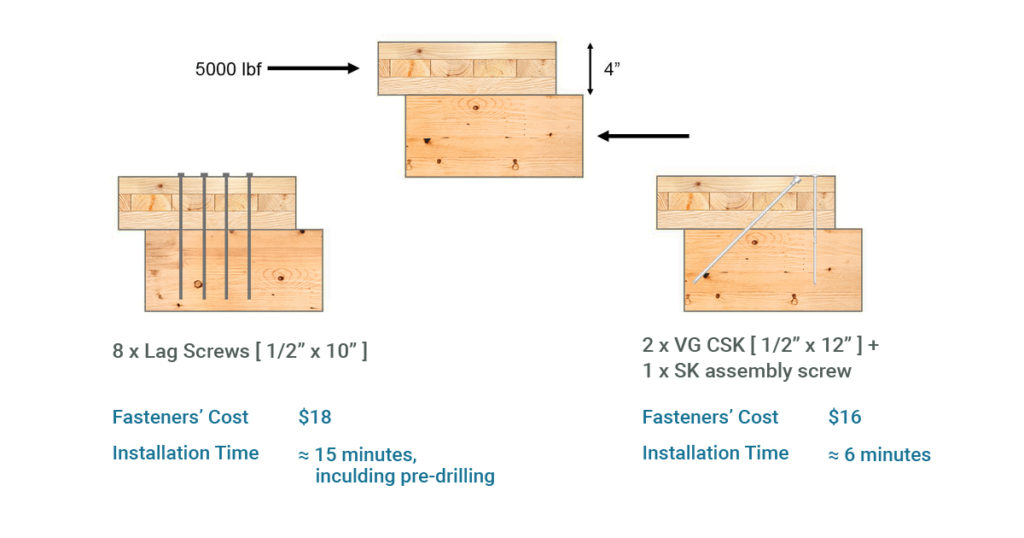

Time savings generally add up to large cost reductions, while for small projects this will have less of an impact. A fully threaded screw may cost more than a similarly sized lag screw, but inclined screw applications allow for higher capacities with fewer screws in smaller timber sections. The figure below shows a short example:

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.