North American mass timber structures must maintain continuous load paths under a range of loading scenarios, including gravity, wind, and seismic effects. While beam hangers are primarily designed to support gravity loads, they may also be required to accommodate incidental axial forces without compromising their load-carrying capacity.

MTC Solutions beam hangers are commonly used in beam-to-column and beam-to-girder connections to support gravity loads. In some applications, these connections may be required to resist axial forces associated with structural integrity requirements, load redistribution, or building movement, while remaining fully engaged and supporting gravity load.

This blog post outlines why axial performance at beam hanger connections matters, how axial behavior was evaluated through testing, and the results of how MTC beam hangers performed under combined gravity and axial loading.

6-minute read.

Why Does Axial Capacity in Beam Hanger Connections Matter?

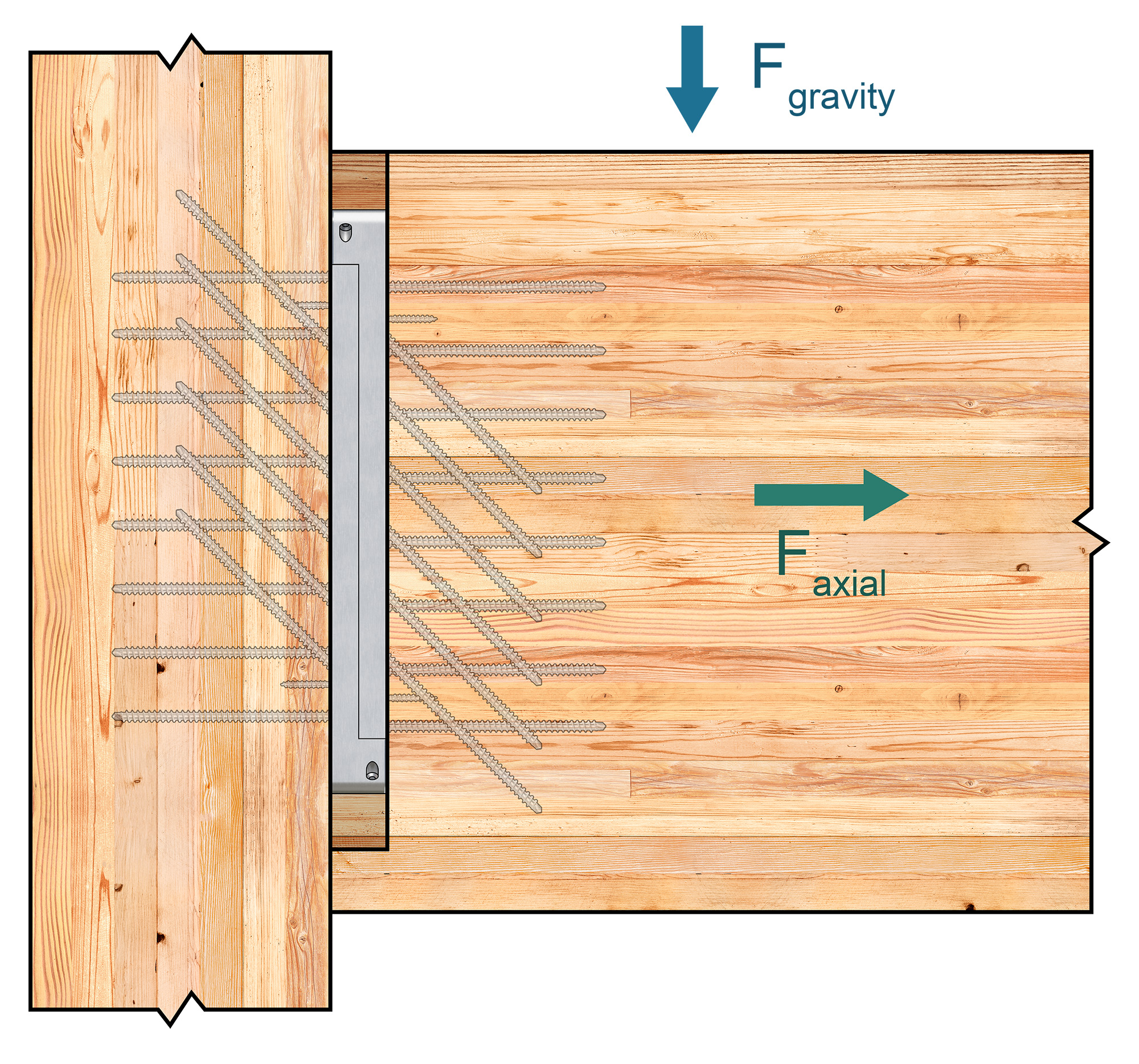

Beam hangers are not traditionally part of a lateral force resisting system; however, gravity connections may still be subjected to incidental axial forces in a wind or seismic event. Because of this, ASCE 7-22 Sections 1.4.3 and 12.1.4 require a positive connection to resist a horizontal force acting parallel to the member (i.e., axial force) of at least 5% of the gravity load (Faxial ≥ 0.05·Fgravity). While the National Building Code of Canada (NBCC) does not specify an explicit axial requirement, the Engineer of Record (EOR) must still consider these forces to maintain a continuous load path and ensure the structural integrity of the building.

Figure 1. Combined Gravity and Axial Loading on a Beam Hanger System

A common approach to addressing axial demand in concealed beam hangers is to calculate axial resistance based on fastener withdrawal or tension capacity. At MTC Solutions we undertook a dedicated testing program to confirm that the calculated axial capacities and recommended interaction approach presented in our design guides were acceptable representations of actual connection behavior.

How is a Beam Hanger System Tested to Evaluate Its Axial Performance?

No standardized protocol exists to test the axial performance of pre-engineered connectors. Therefore, MTC Solutions’ research and development team developed a procedure to do so in collaboration with the University of Northern British Columbia (UNBC) with the goal of simulating realistic conditions.

The APEX, MEGANT, and RICON S VS beam hangers were each tested in two subsequent phases of combined gravity and axial loading:

Gravity load applied to the beam was simulated with a hydraulic ram connected to a load cell. Axial load was controlled via a self-reacting tension testing frame with a fixed displacement rate in accordance with ASTM D7147-21. Load and deformation were monitored throughout testing to observe connection response under combined loading.

Figure 2. Axial Test Setup at UNBC

How do MTC Solutions’ Beam Hangers Perform Under Axial Loading?

All tested beam hangers supported the initial loading step, in which axial force exceeding 5% of the gravity load was applied while the full gravity load was maintained. No significant deformation or visible damage was observed during this phase, confirming that MTC beam hangers can accommodate axial forces associated with structural integrity demands while remaining fully engaged in supporting gravity load.

During the second loading step, gravity load was reduced and axial load was increased until failure. The ultimate axial loads achieved exceeded the minimum integrity demand by a substantial margin while still maintaining sustained gravity load.

Connection response under axial loading was ductile, with deformation occurring in the fasteners and connector components rather than through sudden loss of capacity or brittle failure. This further supports the performance of the hangers under seismic loading, where ductile connection behavior is critical.

For Engineers of Record, these results provide confidence that the axial capacities published in the MTC design guides are representative of actual beam hanger behavior when evaluated using the recommended interaction approach. While beam hangers are not intended to resist lateral loads, the verified axial performance helps support design decisions where incidental axial demand must be considered to maintain a continuous gravity load path.

Through ongoing research, testing, and product development, MTC Solutions focuses on advancing beam hanger systems that balance structural capacity, seismic resilience, fire performance, and constructability. These efforts are intended to support more consistent detailing, reliable installation, and predictable in-service performance across a range of mass timber applications.

If you’d like to learn more about our beam hanger systems for your North American projects, contact our Technical Support Team, and we’ll be there to guide you and your team.

Annex

Further discussion of the axial testing methodology and results is available in the published paper, “Biaxial Resistance of Pre-Engineered Beam Hangers in Glulam” (Authored by Tong F., Ganjali H., & Tannert T.).

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.