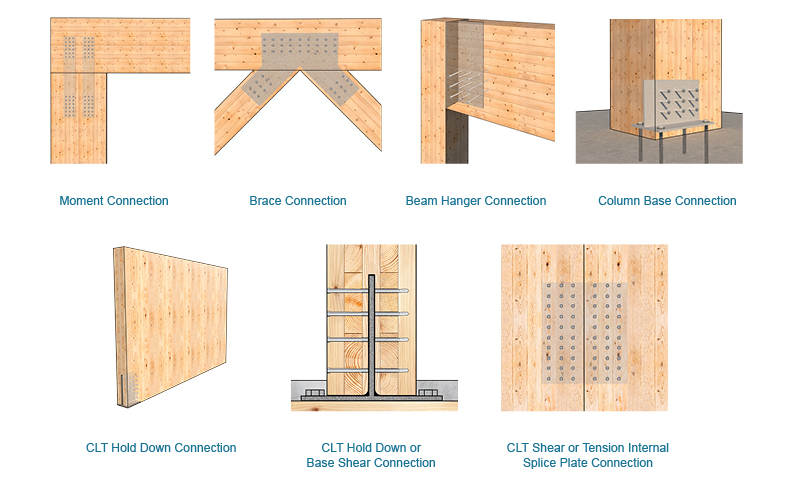

The Self-Drilling Dowel (SDD) can be used in multiple connection scenarios where internal steel plates are used for load transmission. Examples are shown below such as timber moment connections, custom beam hangers and hold down connections.

Approximately 6-minute read.

When designing connections with internal knife plates using our Self-Drilling Dowels, there are a few important details to keep in mind to ensure a proper and simple installation.

Wood member machining.

Before selecting knife plate dimensions, the designer should confirm routing capabilities with the mass timber material supplier. The type of tool used to machine the wood member will directly influence the width and maximum depth of the knife plate slot that may be cut in the timber.

Shape of the saw blade.

Saw blades typically leave a rounded edge saw kerf after machining, which may complicate the installation of a squared edge knife plate. The designer may either design the knife plate with rounded corners or overdesign the slot dimensions to account for the curvature radius.

Depth of knife plate slot.

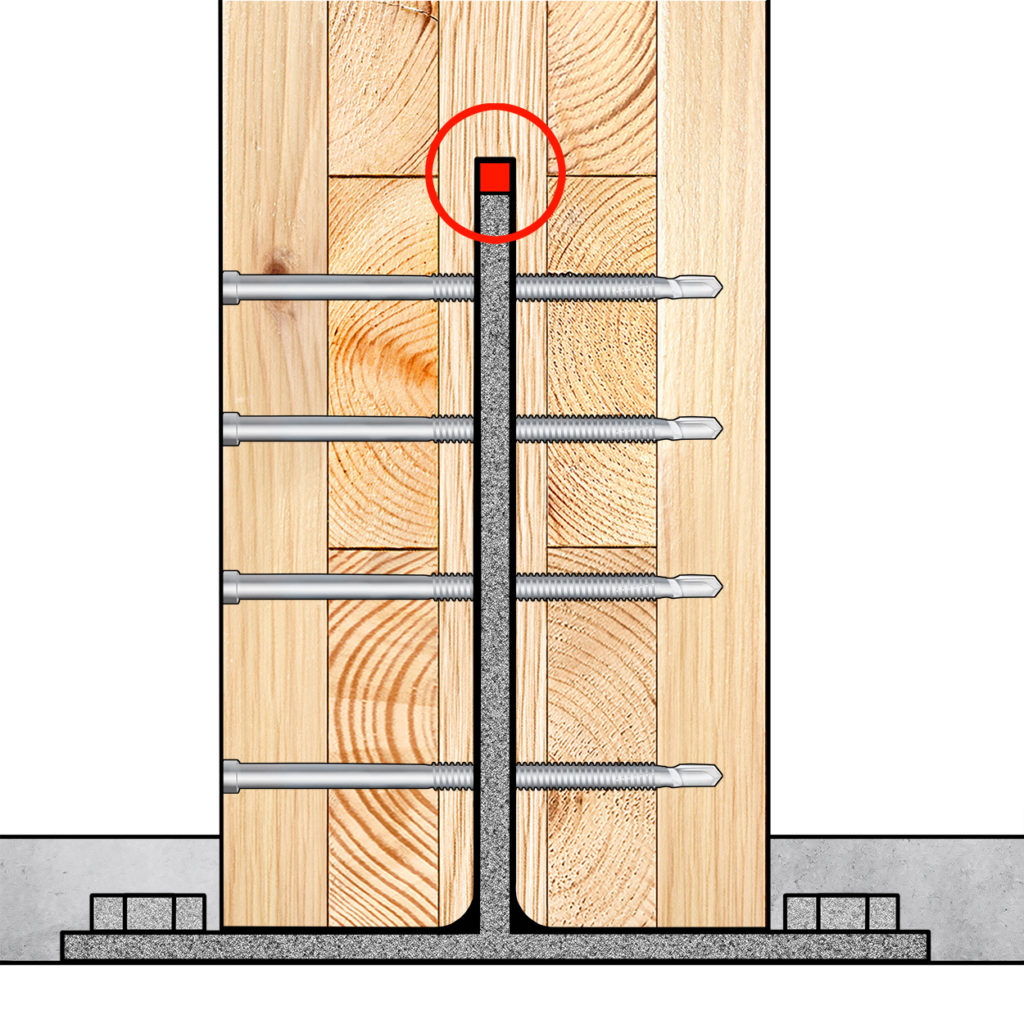

It is recommended to design the knife plate slot to be deeper than the knife plate. If the extremity of the knife plate is in direct contact with the mass timber member under compression loads, a wood splitting effect may occur where the steel plate acts as an axe point separating the wood member in two.

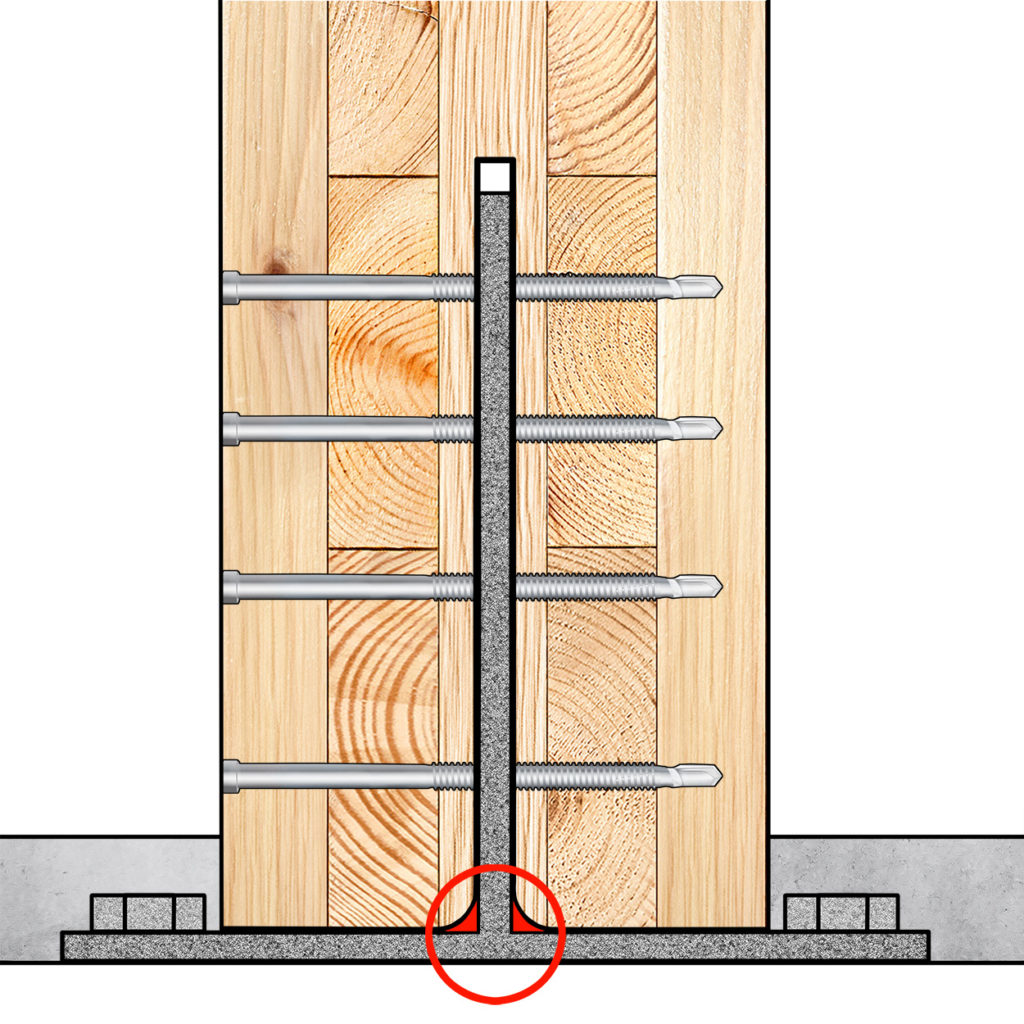

The designer must verify and accommodate the geometry of the base connection of the knife plate. Hot-rolled T-sections may have rounded corners. Similarly, custom assemblies may have welded corners at the base of the knife plate. In both cases, the designer must account for the geometry of the steel connector by bevelling the corners of the wood member, allowing for a clean fit with the steel and easier installation on site.

Swelling and shrinkage.

It is recommended to account for potential wood swelling or shrinkage due to moisture content variation when designing knife plate connections. To do this, the designer should specify a knife plate slot larger than the thickness of the steel plate and should limit the distance between the two outer rows of dowels installed perpendicular to the grain to 5” (125mm)

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.