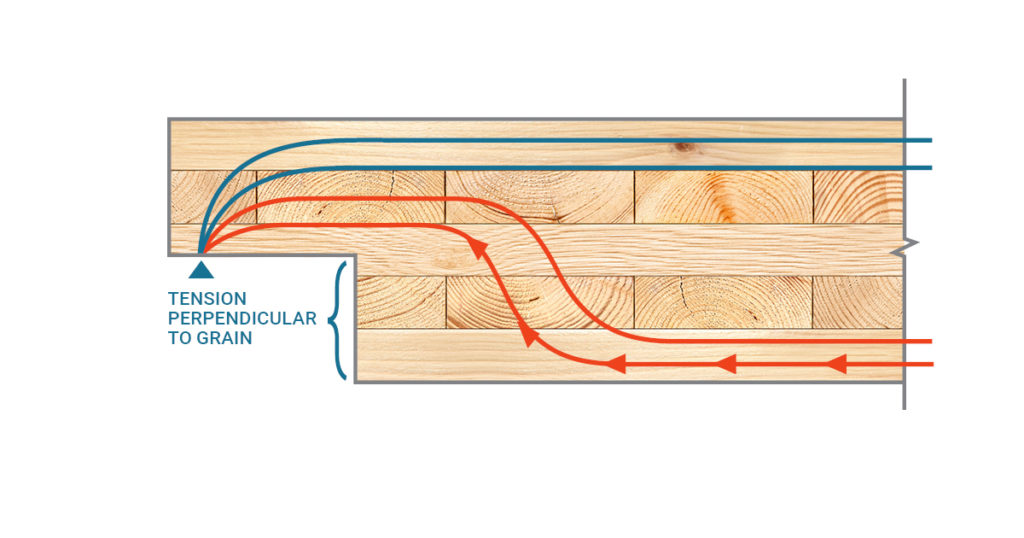

The lap joint is a common panel-to-panel connection employed with CLT panels, largely due to ease of installation. Lap joints are highly effective at transferring shear forces, but designers should be aware that lap joints can be especially vulnerable for out-of-plane loading, as the panel interfaces are deeply notched,

resulting in a perpendicular to grain splitting hazard.

Tension-site notches may result in excessive stresses acting perpendicular to the grain of the panel leading to fracture shear failure. In many cases, ICC-ESR approved fully threaded ASSY fasteners can be designed to transfer these tensile load components, limiting the risk of potential brittle failure modes.

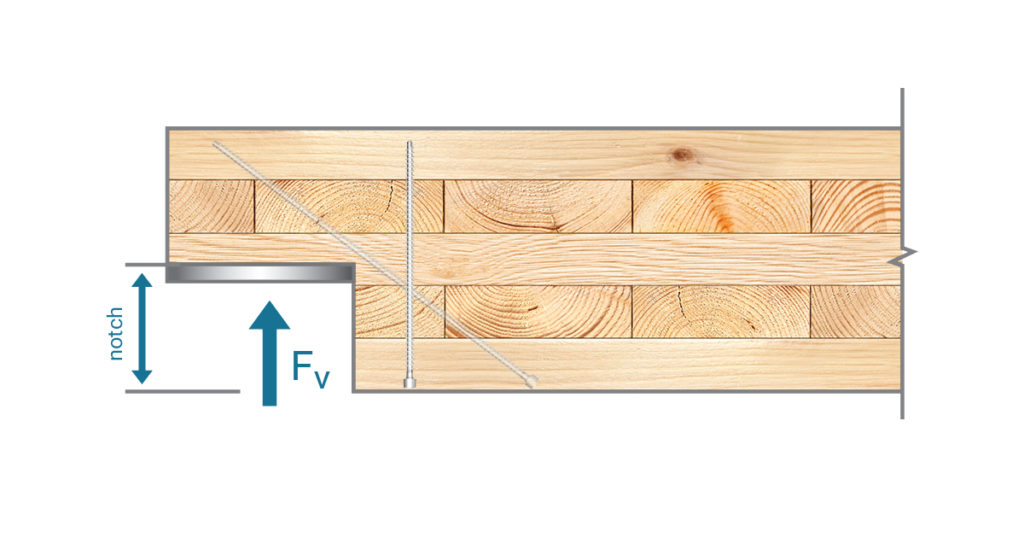

Compressive stresses perpendicular to the grain typically do no cause brittle failure modes. However, in this direction timber strength is generally limited. Designers may compensate for this strength limitation by using fully threaded ASSY screws and taking advantage of their high axial resistance. Compressive load components will be then transmitted into the panel through the screws, where the stresses will be diffused.

This increases the effective bearing area, resulting in a more effective force distribution. In the case of CLT notch reinforcement, a definitive mechanical model has not yet been developed. However, notched CLT panels can certainly be reinforced with ASSY fully threaded screws. A few key points need to be addressed in order to do this.

The mechanical model used to calculate splitting stresses assumes that the wood member is under unidirectional bending. More importantly, it assumes a parabolic shear stress distribution along the cross-section of the member based on Simple Beam Theory. Due to the anisotropic behavior of CLT, lamellas will experience different shear stresses depending on their orientation. This effect is called rolling shear and can limit the CLT’s shear resistance and stiffness in the crossing plies. Reducing the thickness of cross layers may mitigate this issue. ASSY fully threaded screws can be used to reinforce the CLT against shear stresses activated by this panel bending as well as point loads.

To our knowledge, crack formation and propagation in the crossing layers at the notched corner of a lap joint, and the influence of sliding shear fracture, have not yet been investigated. Lamellas are typically glued on their wide face and not their narrow face. This means that cracks can propagate following a path through gaps in the panels rather than developing the full strength of the timber.

Register for a Technical Learning Session

Sign up for MTC Newsletter and keep up to date with all our progress.